Answered step by step

Verified Expert Solution

Question

1 Approved Answer

process control IV. PROJECT SCENARIO The particular level of liquid in the vessel is of great significance in many processes such as distillation columns, evaporators,

process control

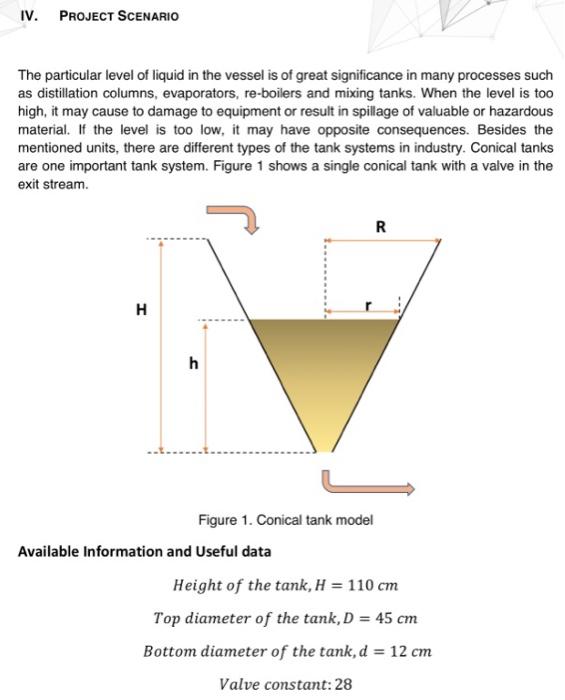

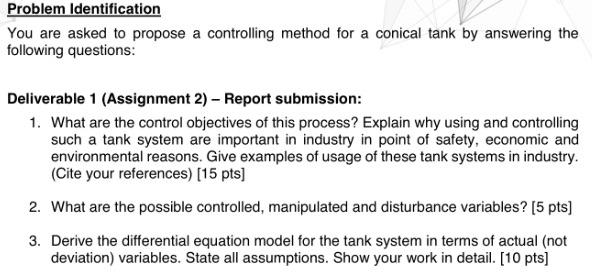

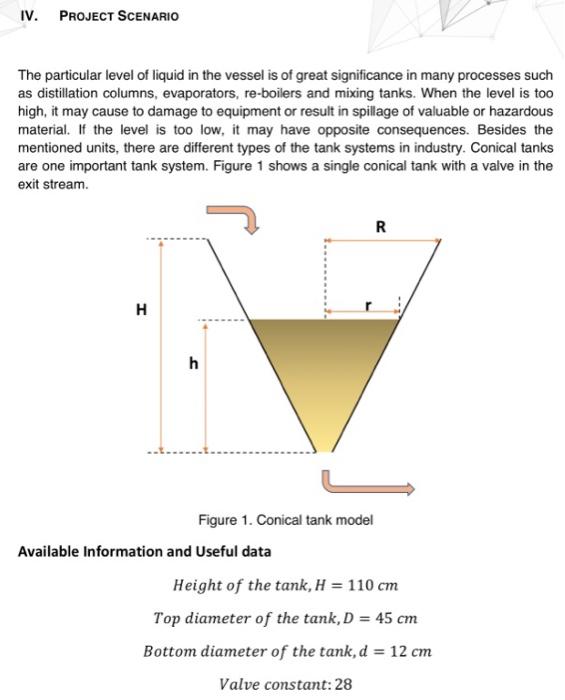

IV. PROJECT SCENARIO The particular level of liquid in the vessel is of great significance in many processes such as distillation columns, evaporators, re-boilers and mixing tanks. When the level is too high, it may cause to damage to equipment or result in spillage of valuable or hazardous material. If the level is too low, it may have opposite consequences. Besides the mentioned units, there are different types of the tank systems in industry. Conical tanks are one important tank system. Figure 1 shows a single conical tank with a valve in the exit stream. R H H h Figure 1. Conical tank model Available Information and Useful data Height of the tank, H = 110 cm Top diameter of the tank, D = 45 cm Bottom diameter of the tank, d = 12 cm Valve constant: 28 Problem Identification You are asked to propose a controlling method for a conical tank by answering the following questions: Deliverable 1 (Assignment 2) - Report submission: 1. What are the control objectives of this process? Explain why using and controlling such a tank system are important in industry in point of safety, economic and environmental reasons. Give examples of usage of these tank systems in industry. (Cite your references) (15 pts) 2. What are the possible controlled, manipulated and disturbance variables? (5 pts] 3. Derive the differential equation model for the tank system in terms of actual (not deviation) variables. State all assumptions. Show your work in detail. [10 pts]

Step by Step Solution

There are 3 Steps involved in it

Step: 1

Get Instant Access to Expert-Tailored Solutions

See step-by-step solutions with expert insights and AI powered tools for academic success

Step: 2

Step: 3

Ace Your Homework with AI

Get the answers you need in no time with our AI-driven, step-by-step assistance

Get Started