Answered step by step

Verified Expert Solution

Question

1 Approved Answer

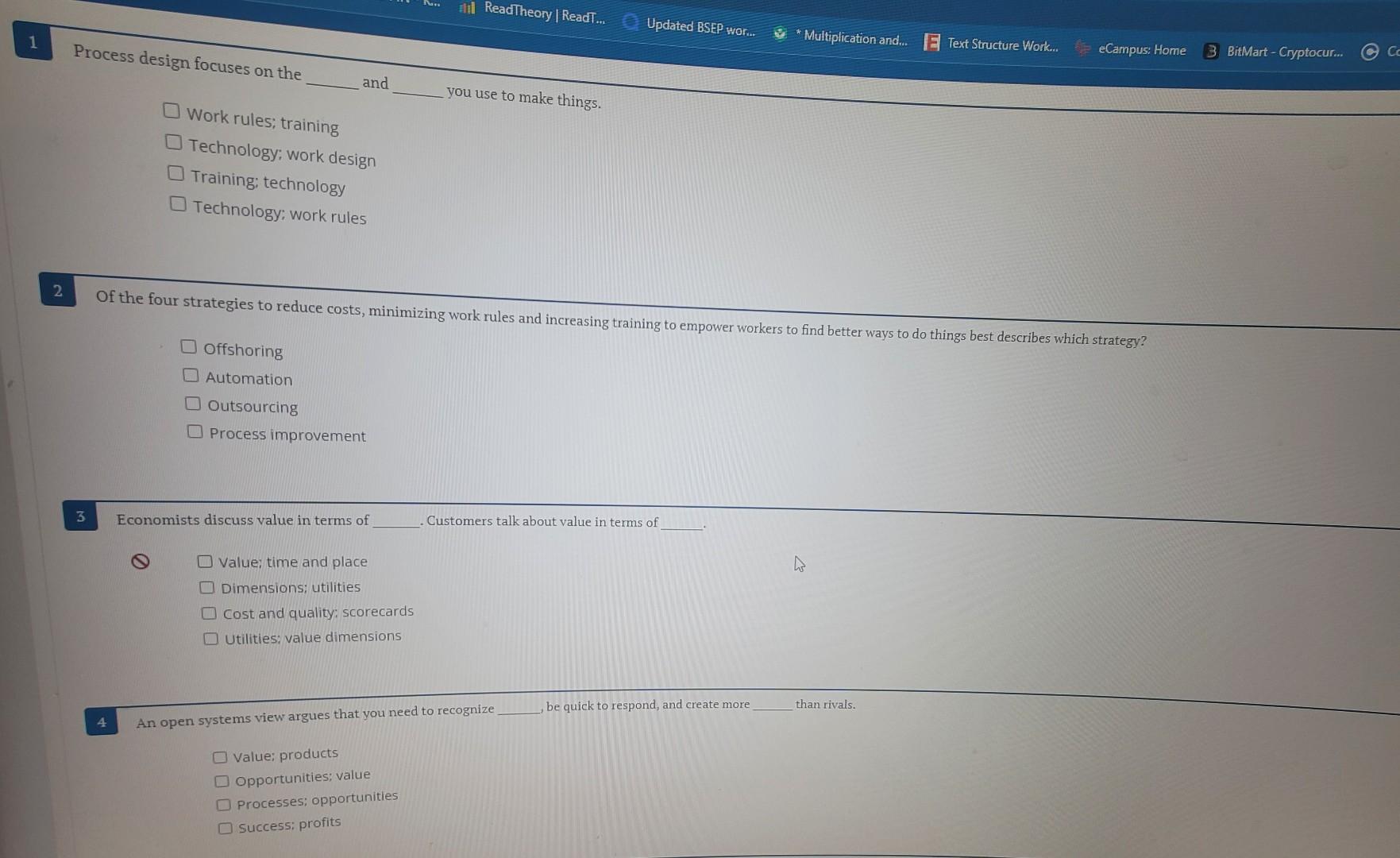

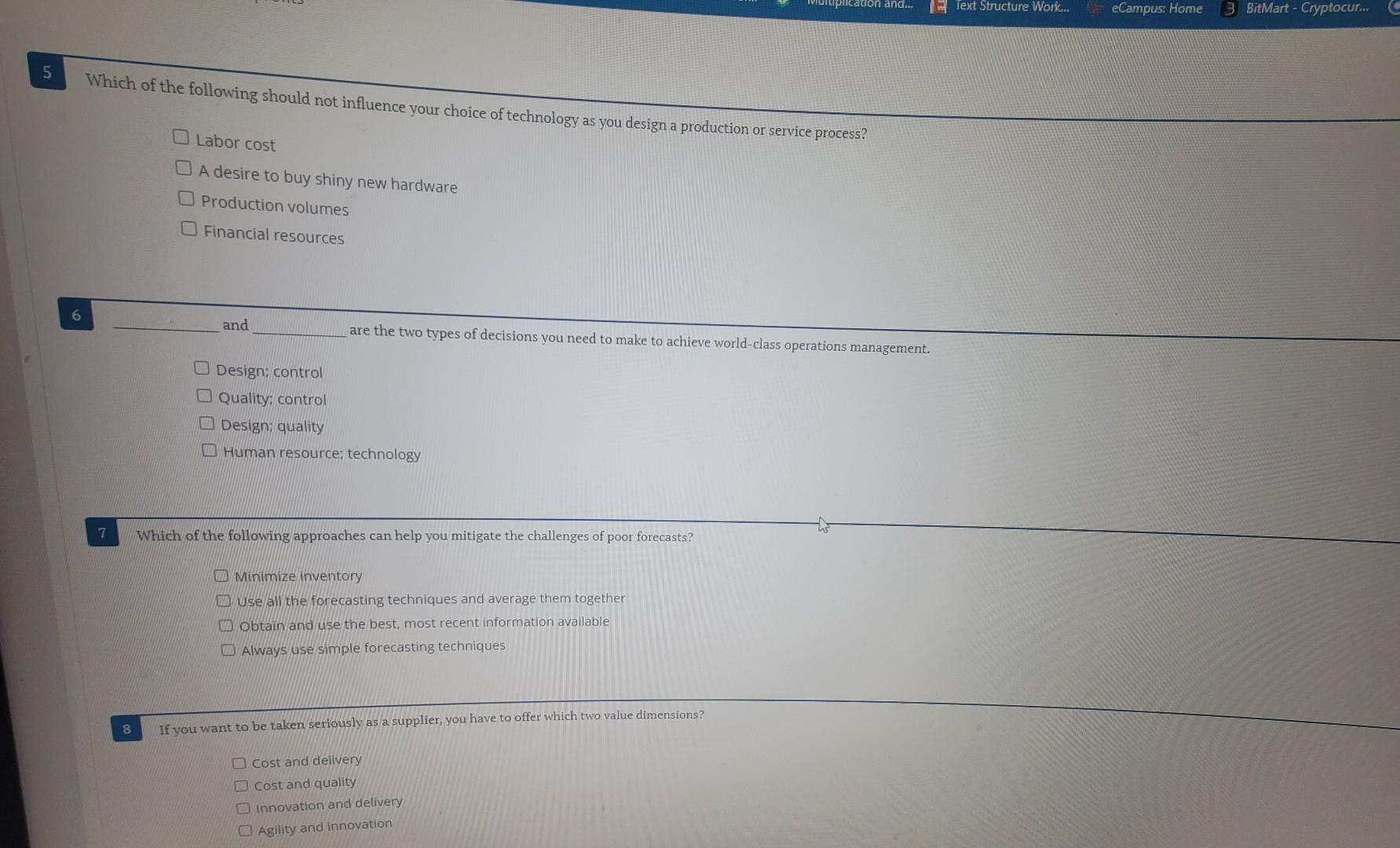

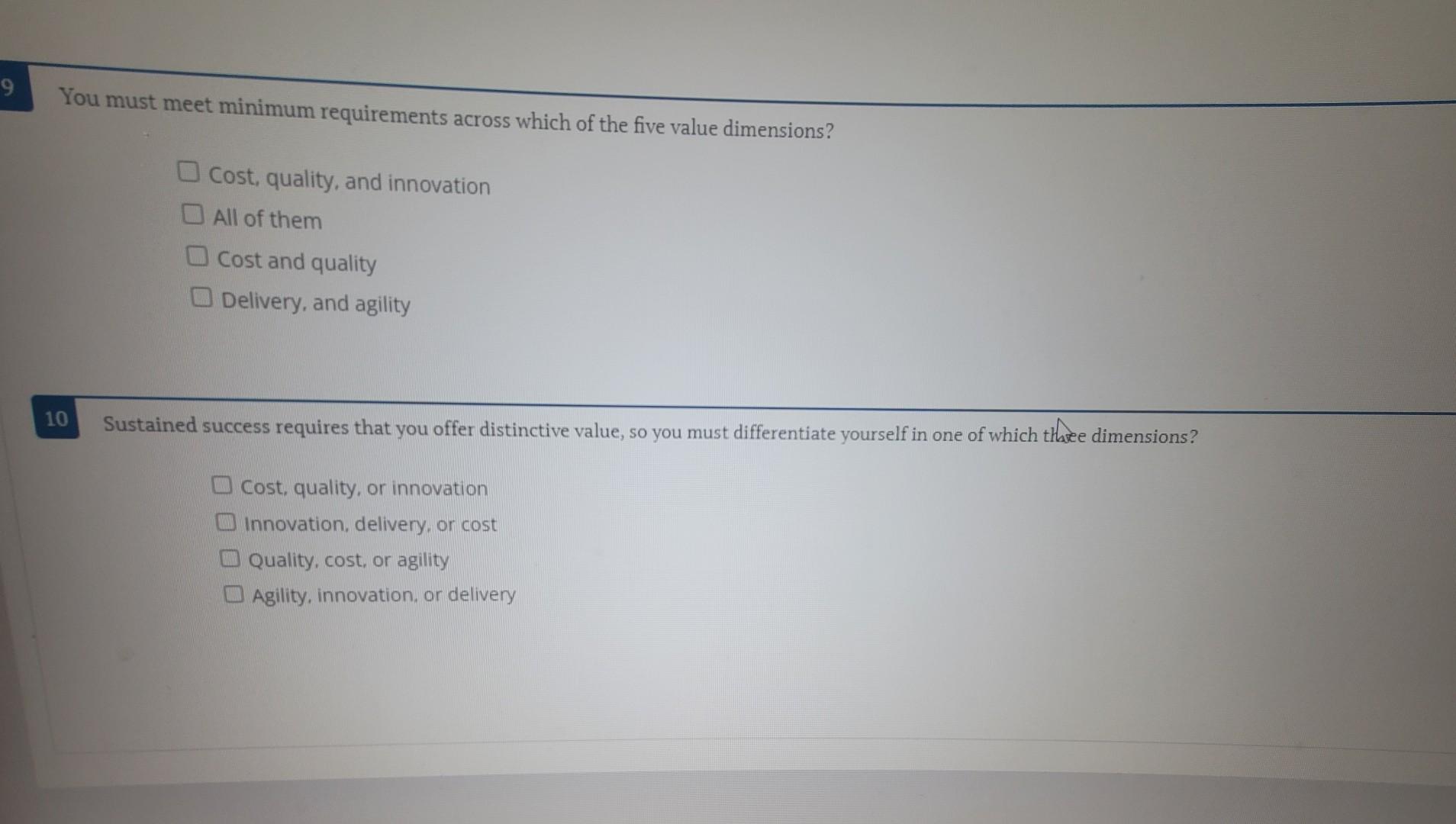

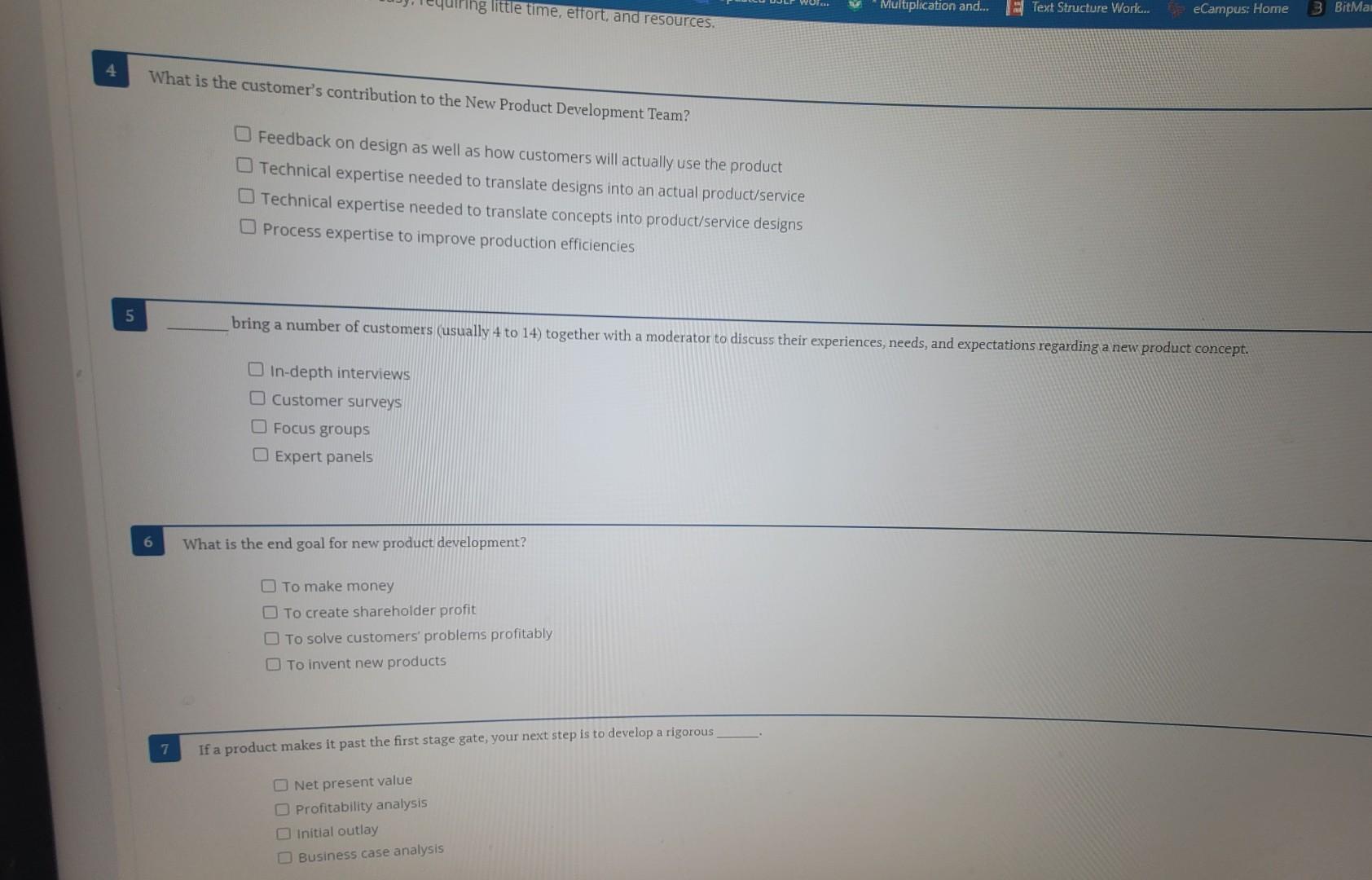

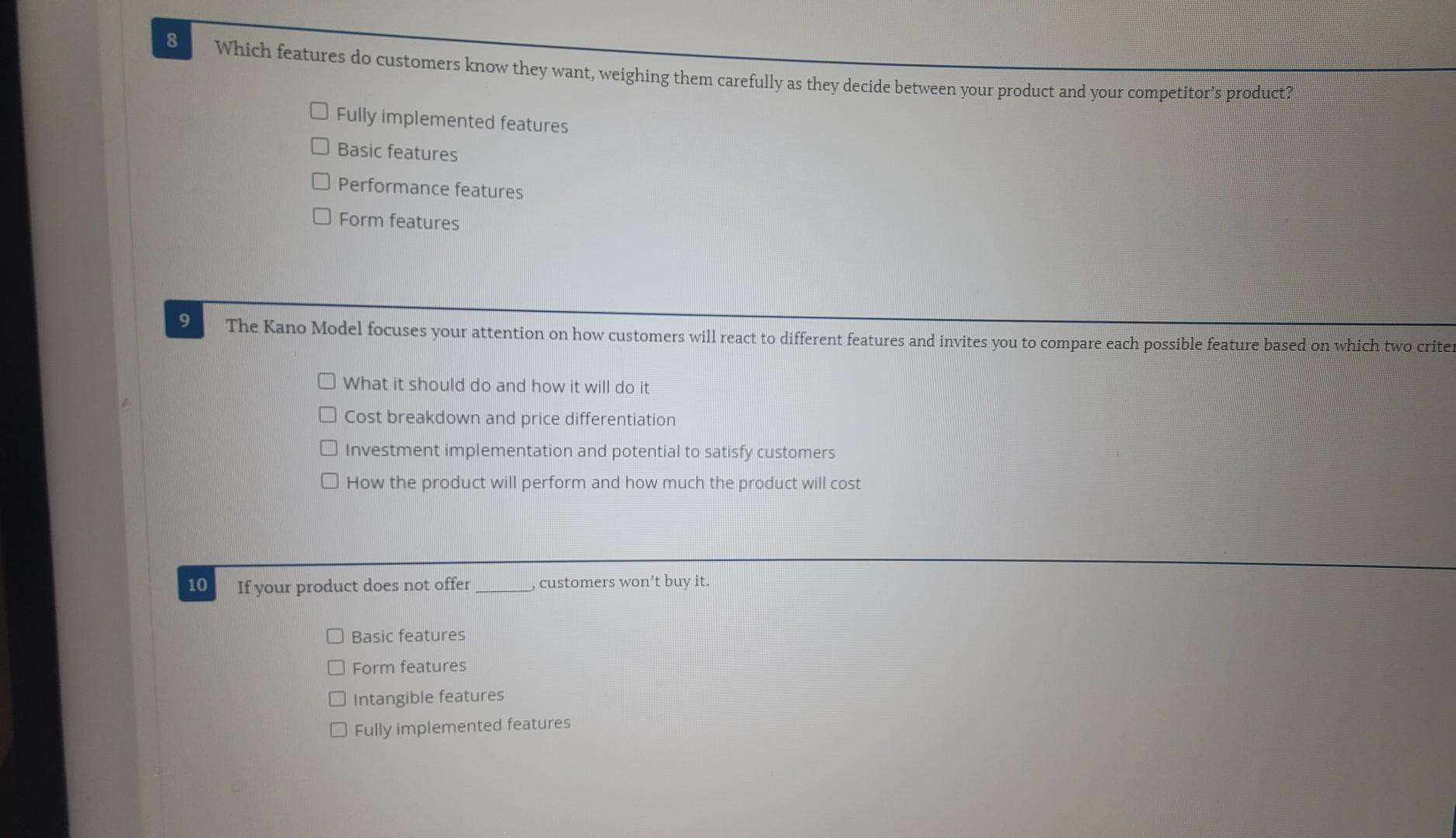

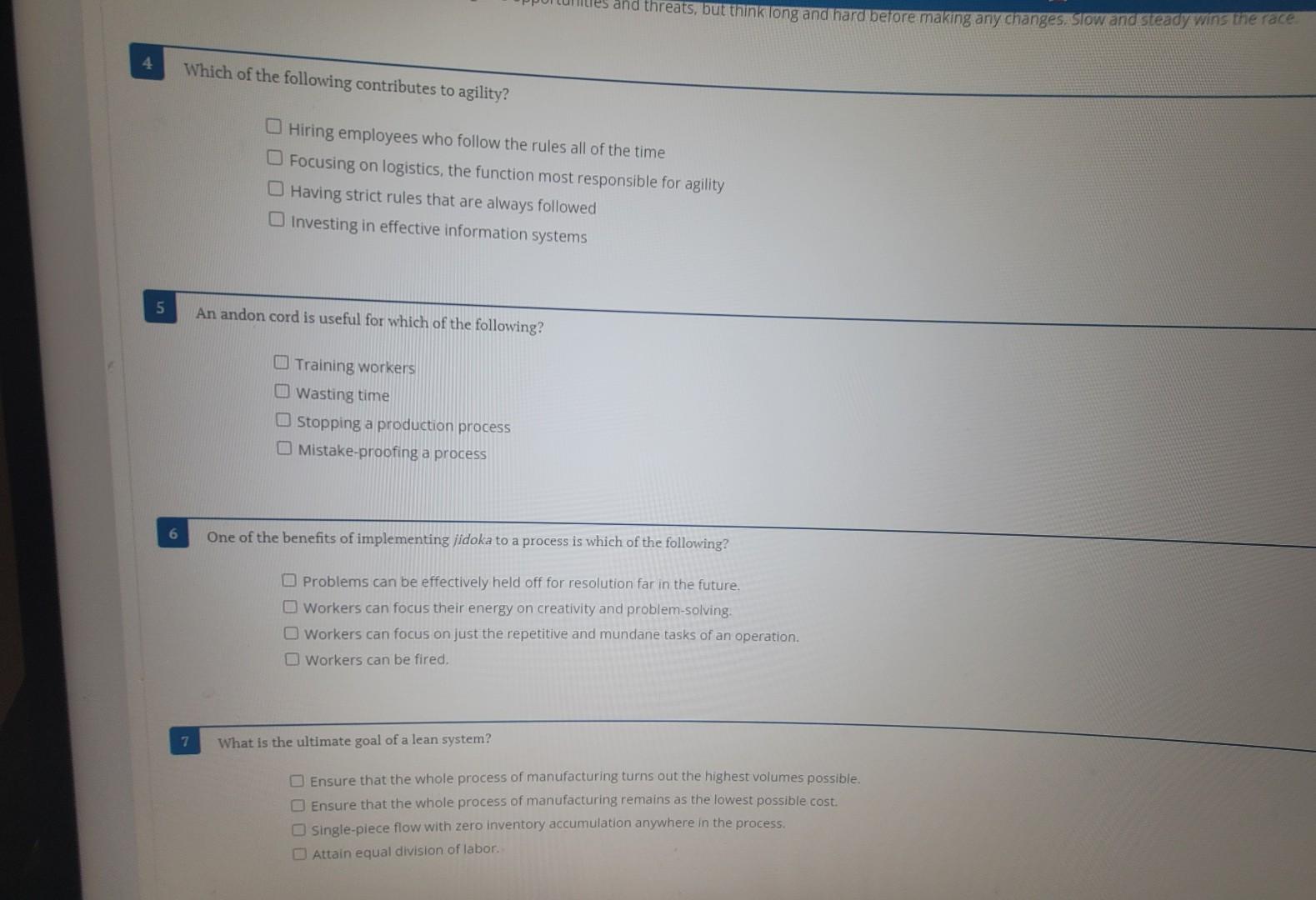

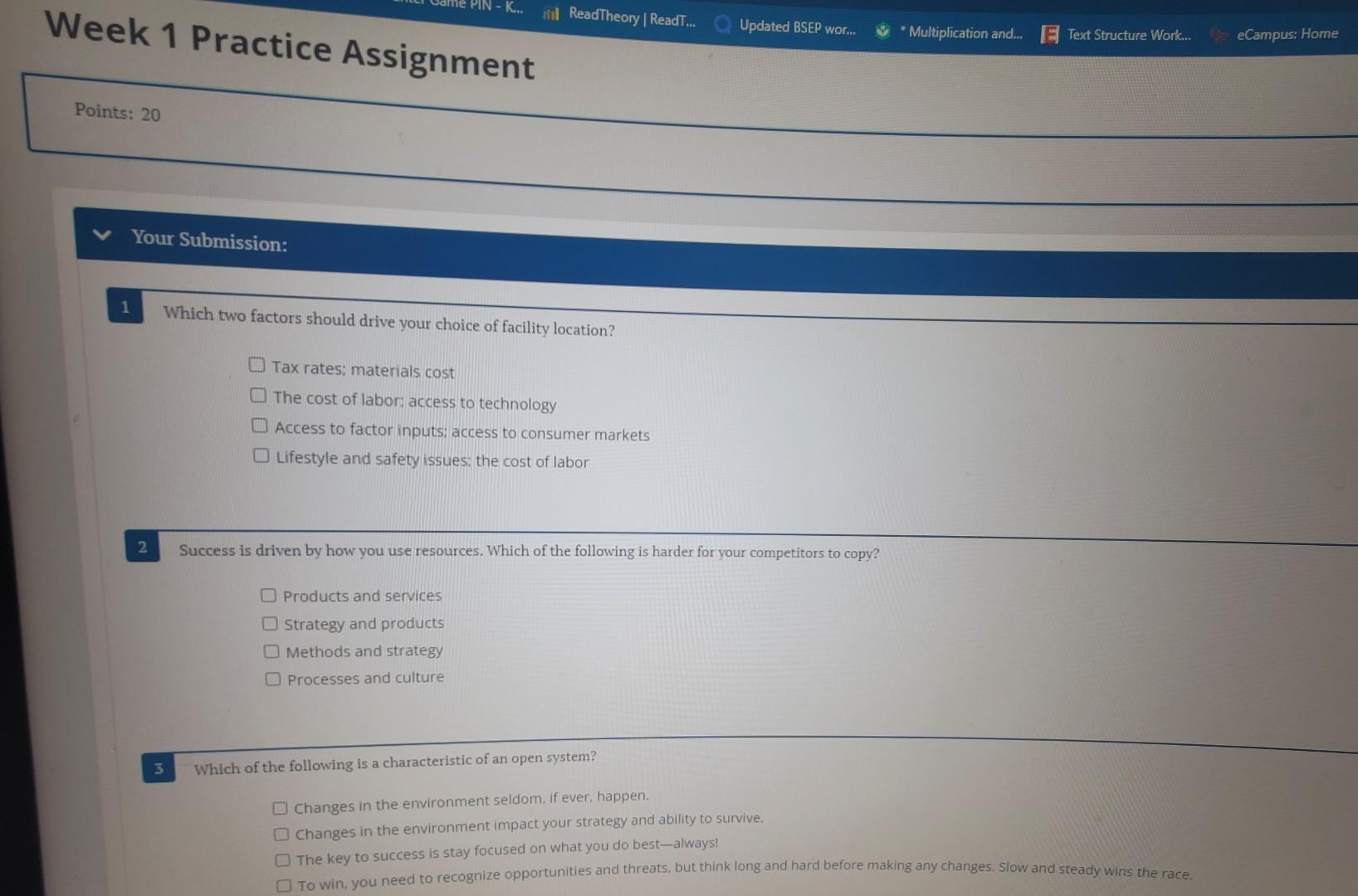

Process design focuses on the Multiplication and... Text Structure Work... EC ECmpus: Home and Work rules; training you use to make things. Technology; work design

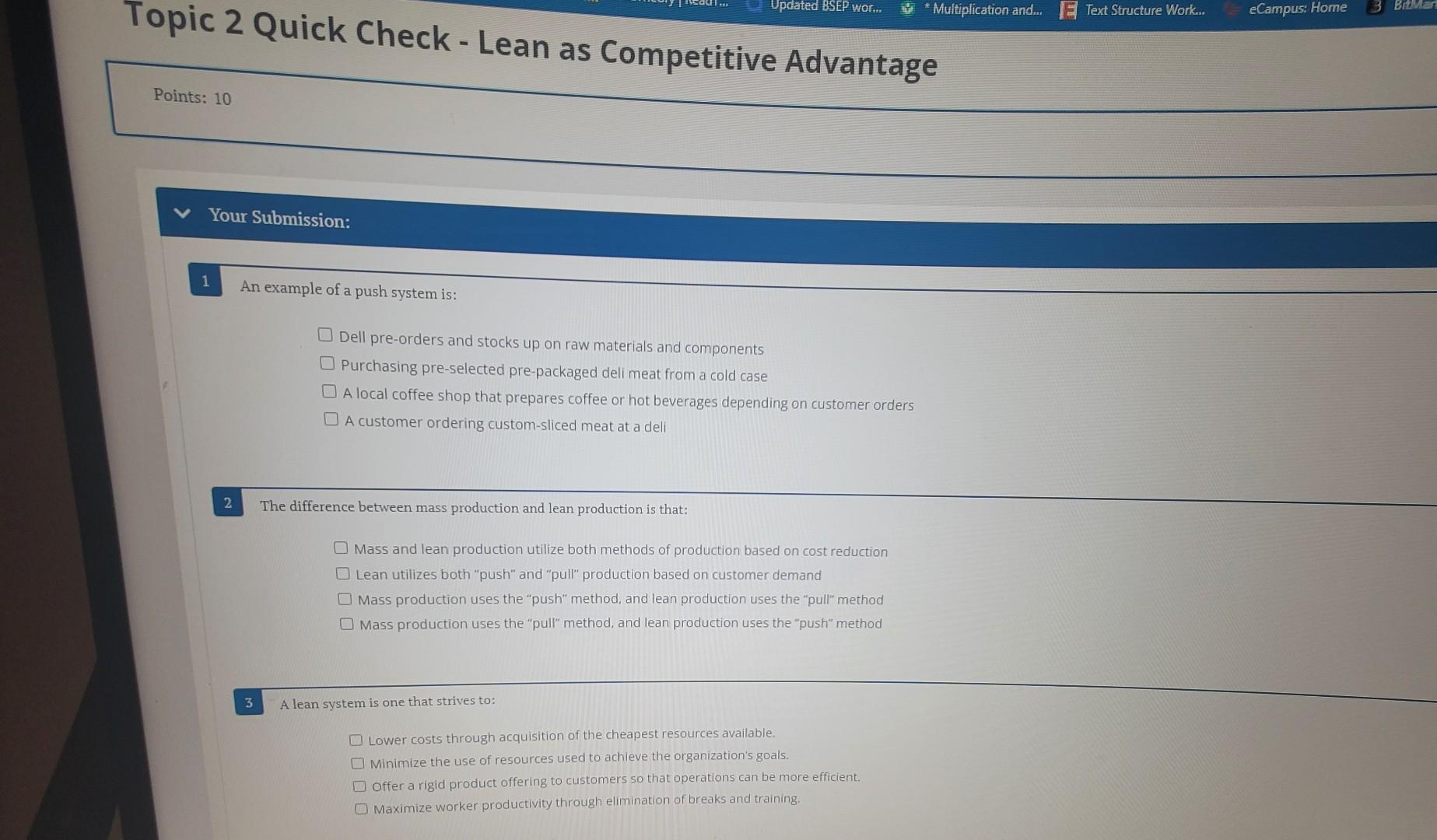

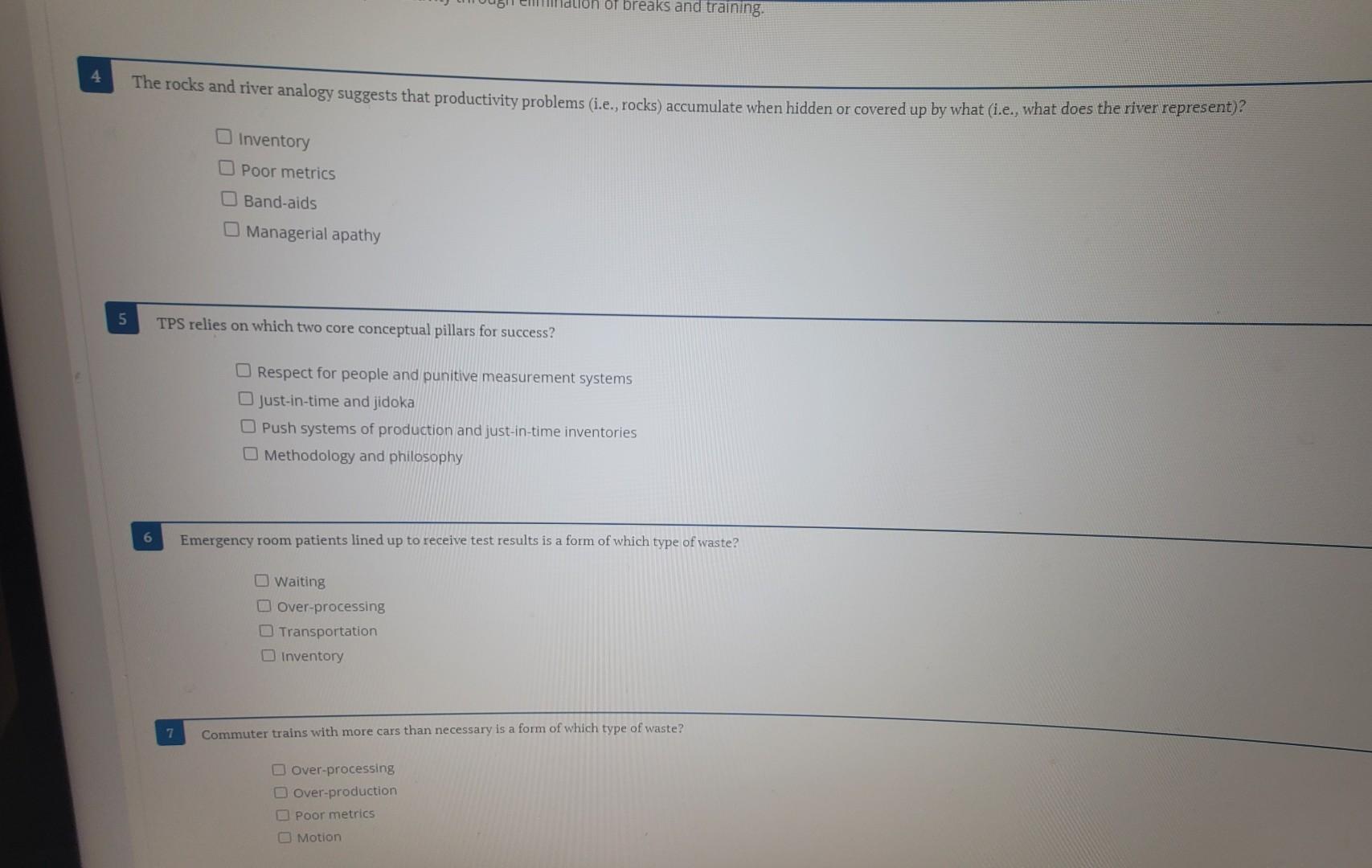

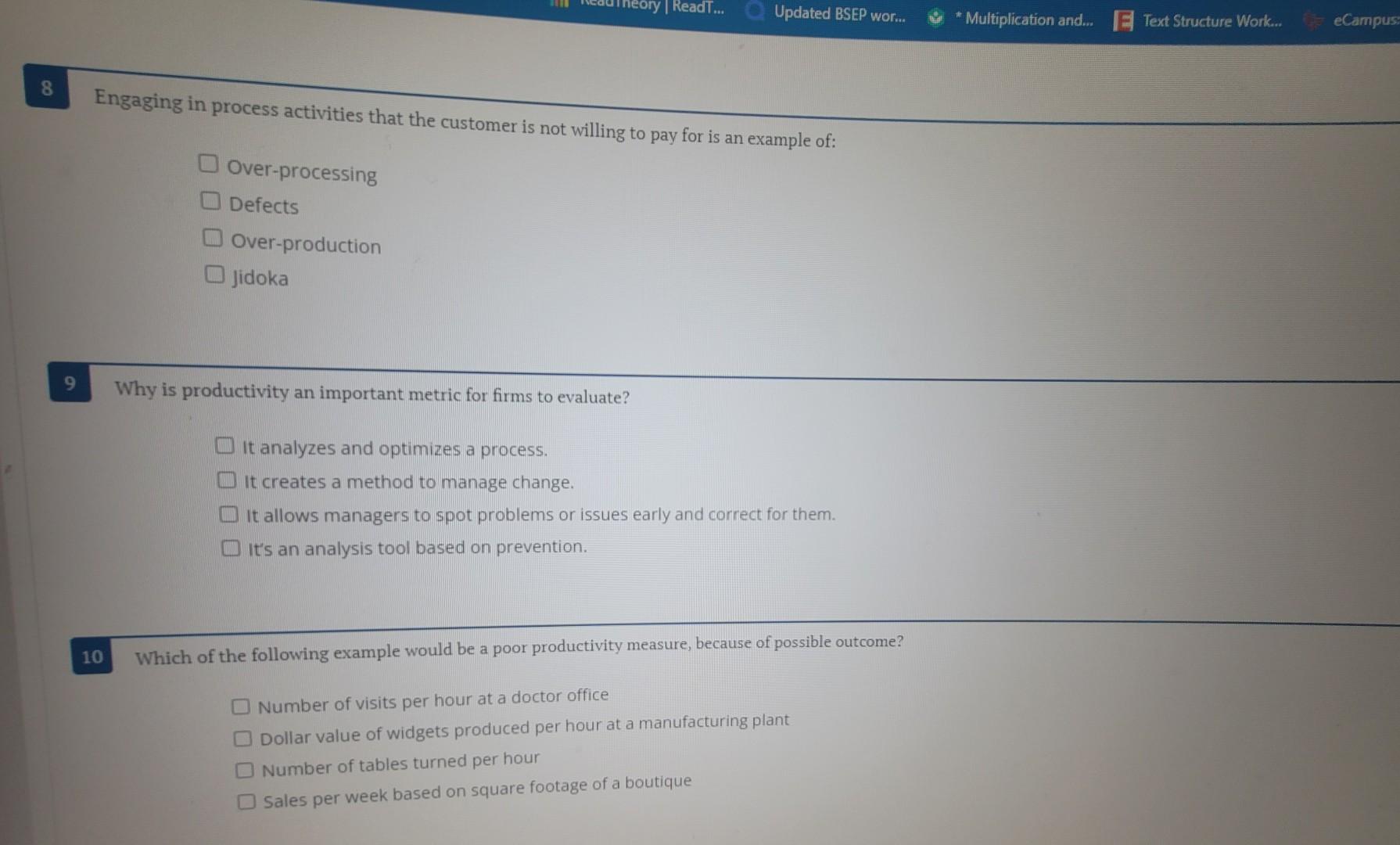

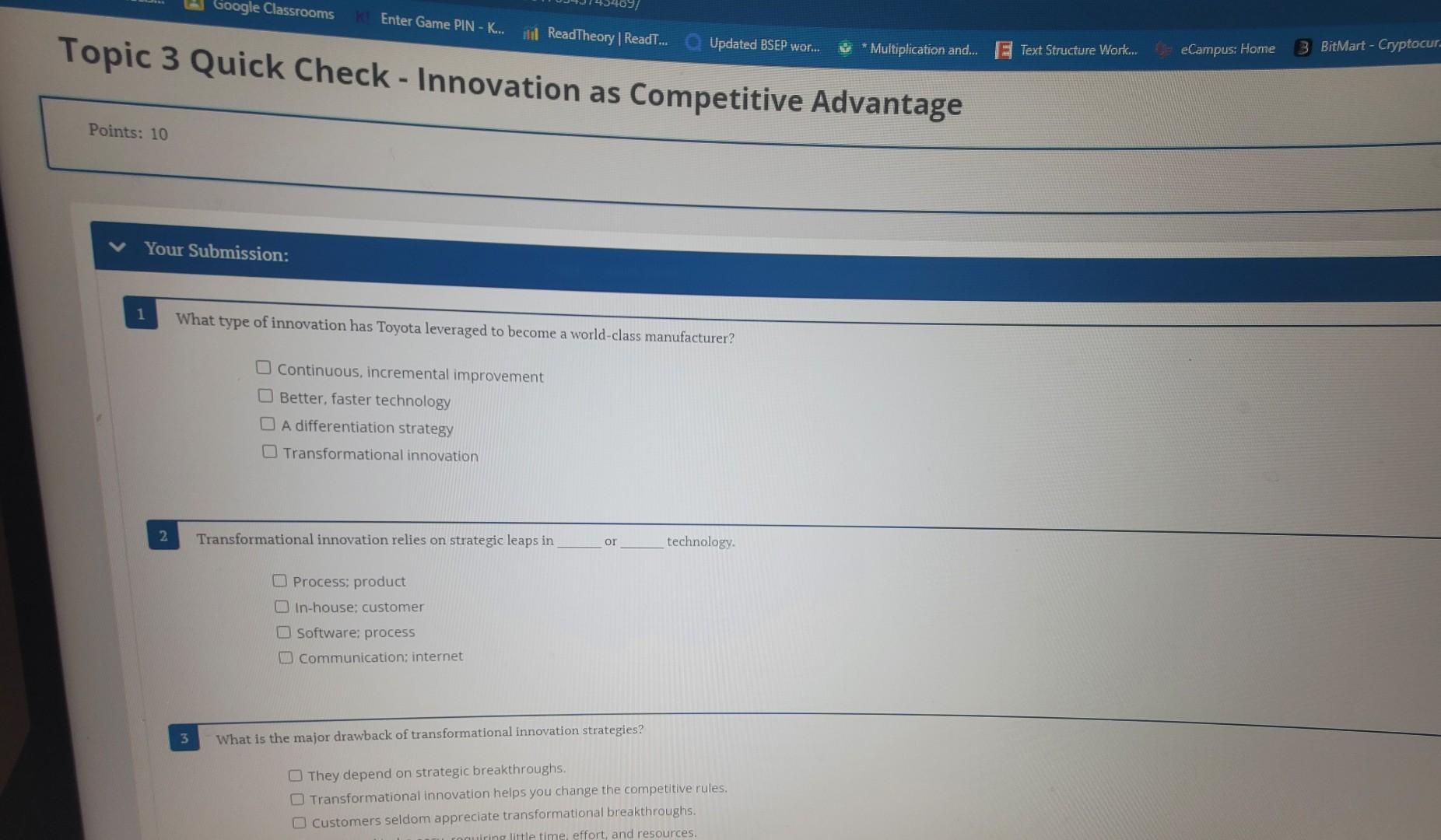

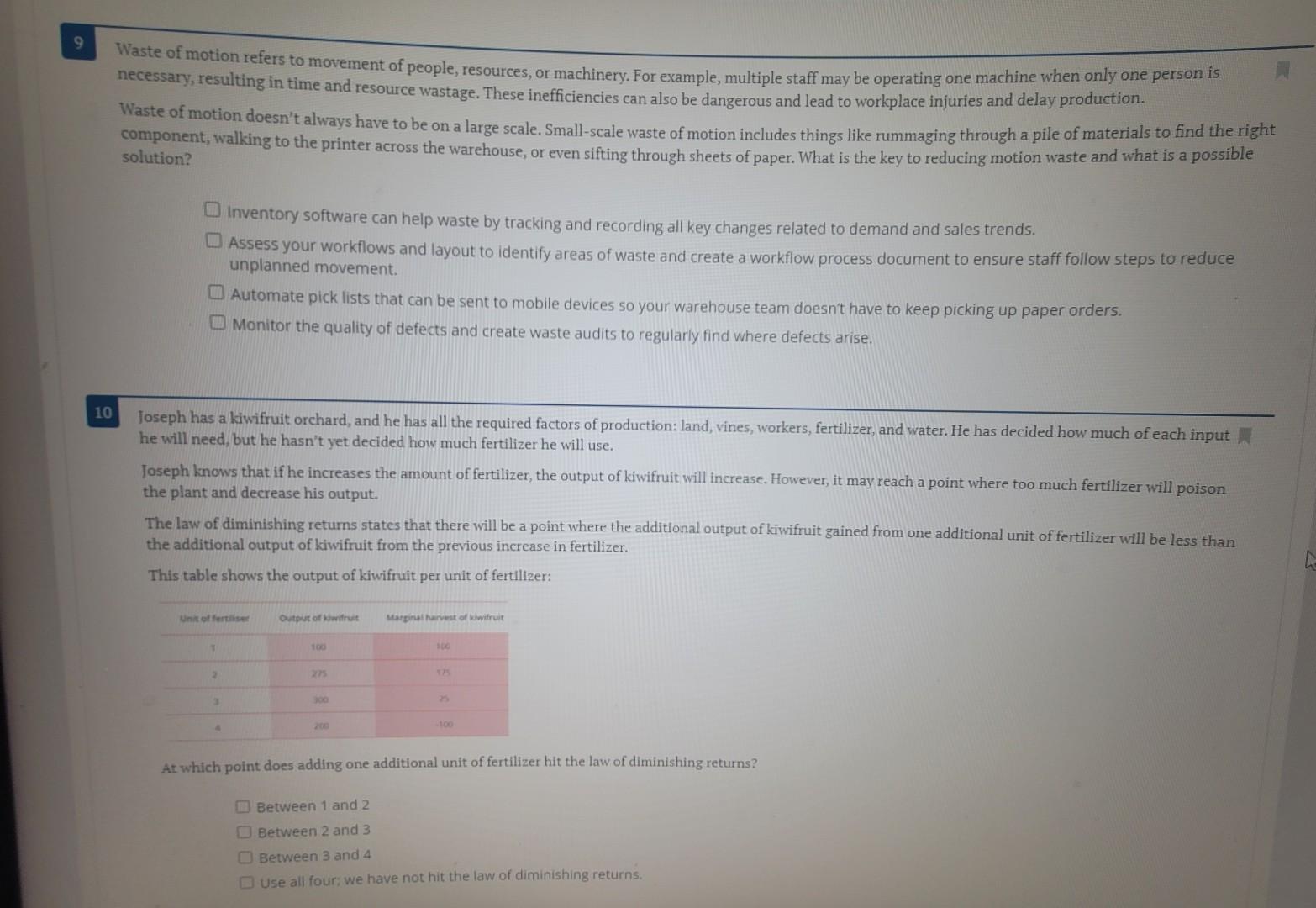

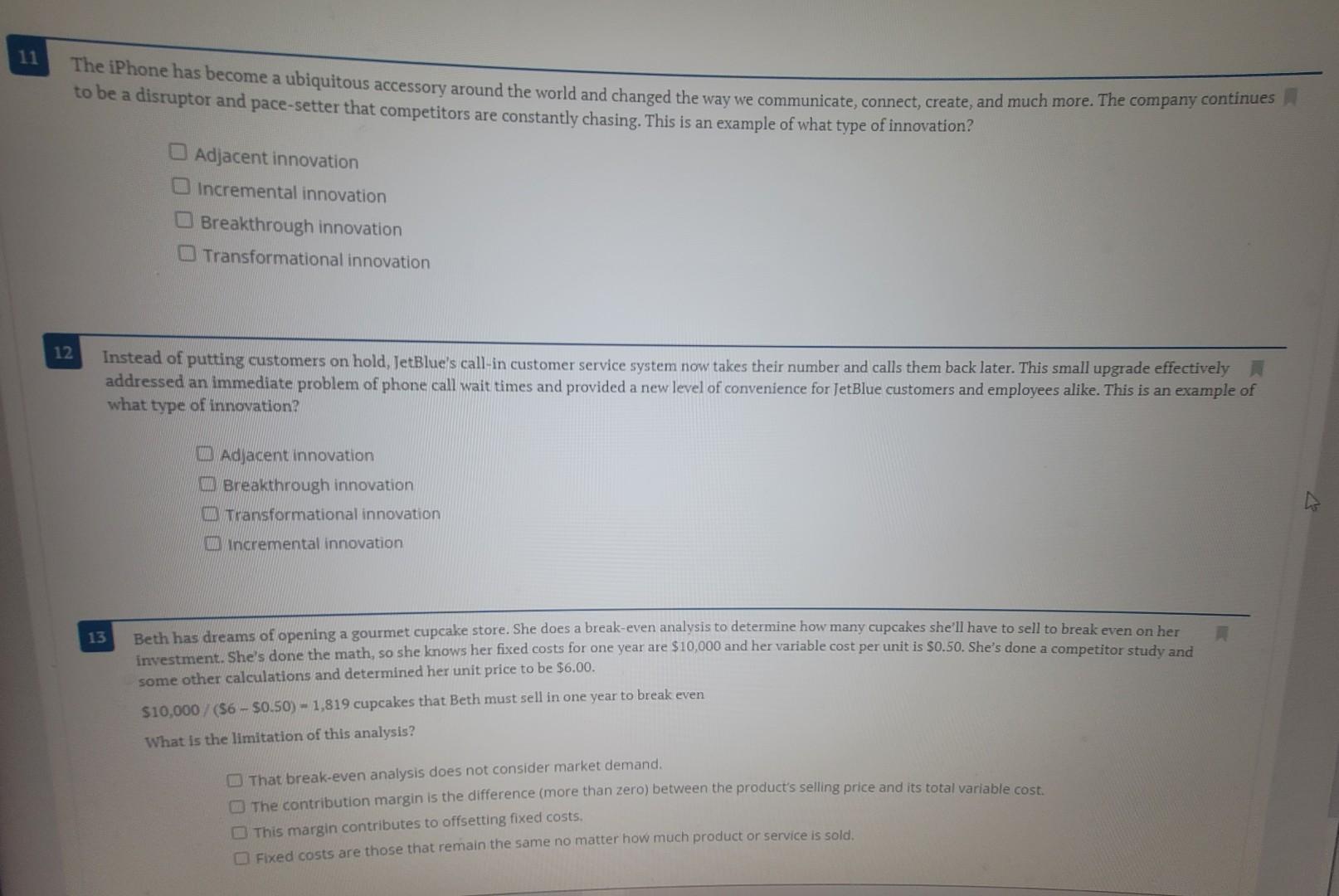

Process design focuses on the Multiplication and... Text Structure Work... EC ECmpus: Home and Work rules; training you use to make things. Technology; work design Training; technology Technology; work rules 2 Of the four strategies to reduce costs, minimizing work rules and increasing training to empower workers to find better ways to do things best describes which strategy? Offshoring Automation Outsourcing Process improvement 3 Economists discuss value in terms of . Customers talk about value in terms of Value; time and place Dimensions; utilities Cost and quality: scorecards Utilities: value dimensions 4 An open systems view argues that you need to recognize be quick to respond, and create more than rivals. Value; products Opportunities; value Processes; opportunities Success: profits Which of the following should not influence your choice of technology as you design a production or service process? Labor cost A desire to buy shiny new hardware Production volumes Financial resources and are the two types of decisions you need to make to achieve world-class operations management. Design; control Quality; control Design; quality Human resource; technology 7 Which of the following approaches can help you mitigate the challenges of poor forecasts? Minimize inventory Use all the forecasting techniques and average them together Obtain and use the best, most recent information available Always use simple forecasting techniques 8 If you want to be taken seriously as a supplier, you have to offer which two value dimensions? cost and delivery cost and quality innovation and delivery Agility and innovation You must meet minimum requirements across which of the five value dimensions? Cost, quality, and innovation All of them Cost and quality Delivery, and agility 10 Sustained success requires that you offer distinctive value, so you must differentiate yourself in one of which thare dimensions? Cost, quality, or innovation Innovation, delivery, or cost Quality, cost, or agility Agility, innovation, or delivery Dell pre-orders and stocks up on raw materials and components Purchasing pre-selected pre-packaged deli meat from a cold case A local coffee shop that prepares coffee or hot beverages depending on customer orders A customer ordering custom-sliced meat at a deli The difference between mass production and lean production is that: Mass and lean production utilize both methods of production based on cost reduction Lean utilizes both "push" and "pull" production based on customer demand Mass production uses the "push" method, and lean production uses the "pull" method Mass production uses the "pull" method, and lean production uses the "push" method 3 A lean system is one that strives to: Lower costs through acquisition of the cheapest resources available. Minimize the use of resources used to achieve the organization's goals. Offer a rigid product offering to customers so that operations can be more efficient. Maximize worker productivity through elimination of breaks and training. The rocks and river analogy suggests that productivity problems (i.e., rocks) accumulate when hidden or covered up by what (i.e., what does the river represent)? Inventory Poor metrics Band-aids Managerial apathy 5 TPS relies on which two core conceptual pillars for success? Respect for people and punitive measurement systems Just-in-time and jidoka Push systems of production and just-in-time inventories Methodology and philosophy 6 Emergency room patients lined up to receive test results is a form of which type of waste? Waiting Over-processing Transportation Inventory 7 Commuter trains with more cars than necessary is a form of which type of waste? Over-processing Over-production poor metrics Motion Engaging in process activities that the customer is not willing to pay for is an example of: Over-processing Defects Over-production Jidoka Why is productivity an important metric for firms to evaluate? It analyzes and optimizes a process. It creates a method to manage change. It allows managers to spot problems or issues early and correct for them. It's an analysis tool based on prevention. 10 Which of the following example would be a poor productivity measure, because of possible outcome? Number of visits per hour at a doctor office Dollar value of widgets produced per hour at a manufacturing plant Number of tables turned per hour Sales per week based on square footage of a boutique What type of innovation has Toyota leveraged to become a world-class manufacturer? Continuous, incremental improvement Better, faster technology A differentiation strategy Transformational innovation Transformational innovation relies on strategic leaps in or technology. Process: product In-house; customer Software: process Communication: internet 3 What is the major drawback of transformational innovation strategies? They depend on strategic breakthroughs. Transformational innovation helps you change the competitive rules. Customers seldom appreciate transformational breakthroughs. What is the customer's contribution to the New Product Development Team? Feedback on design as well as how customers will actually use the product Technical expertise needed to translate designs into an actual product/service Technical expertise needed to translate concepts into product/service designs Process expertise to improve production efficiencies bring a number of customers (usually 4 to 14 ) together with a moderator to discuss their experiences, needs, and expectations regarding a new product concept. In-depth interviews Customer surveys Focus groups Expert panels 6 What is the end goal for new product development? To make money To create shareholder profit To solve customers' problerns profitably To invent new products 7 If a product makes it past the first stage gate, your next step is to develop a rigorous Net present value Profitability analysis Initial outlay Business case analysis Which features do customers know they want, weighing them carefully as they decide between your product and your competitor's product? Fully implemented features Basic features Performance features Form features The Kano Model focuses your attention on how customers will react to different features and invites you to compare each possible feature based on which two crite What it should do and how it will do it Cost breakdown and price differentiation Investment implementation and potential to satisfy customers How the product will perform and how much the product will cost 10 If your product does not offer , customers won't buy it. Basic features Form features Intangible features Fully implemented features 4 Which of the following contributes to agility? Hiring employees who follow the rules all of the time Focusing on logistics, the function most responsible for agility Having strict rules that are always followed Investing in effective information systems 5 An andon cord is useful for which of the following? Training workers Wasting time Stopping a production process Mistake-proofing a process 6 One of the benefits of implementing jidoka to a process is which of the following? Problems can be effectively held off for resolution far in the future. Workers can focus their energy on creativity and problem-solving. Workers can focus on just the repetitive and mundane tasks of an operation. Workers can be fired. 7 What is the ultimate goal of a lean system? Ensure that the whole process of manufacturing turns out the highest volumes possible. Ensure that the whole process of manufacturing remains as the lowest possible cost. Single-piece flow with zero inventory accumulation anywhere in the process. Attain equal division of labor. Which two factors should drive your choice of facility location? Tax rates; materials cost The cost of labor: access to technology Access to factor inputs: access to consumer markets Lifestyle and safety issues; the cost of labor Success is driven by how you use resources. Which of the following is harder for your competitors to copy? Products and services Strategy and products Methods and strategy Processes and culture 3 Which of the following is a characteristic of an open system? Changes in the environment seldom, if ever, happen. Changes in the environment impact your strategy and ability to survive. The key to success is stay focused on what you do best-always! To win, you need to recognize opportunities and threats, but think long and hard before making any changes, Slow and steady wins the race. Which of the following are important reasons to involve suppliers early in the NPD process? Suppliers often possess important technical expertise related to processes or products; Suppliers can share designs they have obtained from other customer Suppliers often possess vital materials expertise; Suppliers often possess important technical expertise related to processes or products Suppliers can share designs they have obtained from other customers; Suppliers are expert in packing and shipping Suppliers are expert in packing and shipping; Suppliers often possess vital materials expertise In a sequential, functionally oriented product design process, what almost always happens when an idea gets tossed from one function to another? Product launch is delayed and products get closer to production. Costs go up and product launch is delayed. Product gets closer to production and launch is delayed. Products are improved and costs go up. 10 During the screening/scoping phase of new product development, you should ask two questions, which of the following are those questions? Will the product meet the competitive test? Does the product really fit the product strategy? Does the product really fit the product strategy? How much profit will this product give the firm? Who is the target market for this new product? Does the product really fit the product strategy? How much profit will this product give the firm? Who is the target market for this new product? Which of the following is an example of form utility? A car manufacturing company could sell all the parts of their cars separately. However, by assembling the parts (and manufacturing cars), this company adds significant value for their customers. If a car manufacturer sells exclusively within the US, buying a car is not very attractive for Europeans. However, if the company decides to open dealerships across Europe and sell cars overseas, the availability of its cars for European customers increases. Customers often have to wait several weeks or even months for a new car. However, many of them need their vehicles as soon as possible. Thus, if the manufacturer manages to reduce delivery times by even just a few days, its cars become more attractive to potential customers. This utility can be created whenever a client is handed the keys to their new car, simply because from that moment they are free to do whatever they want to do with it. 2 Which of the following is an example of time utility? If a car manufacturer sells exclusively within the US, buying a car is not very attractive for Europeans. However, if the company decides to open dealerships across Europe and sell cars overseas, the availability of its cars for European customers increases. Customers often have to wait several weeks or even months for a new car. However. many of them need their vehicles as soon as possible. Thus. If the manufacturer manages to reduce delivery times by even just a few days, its cars become more attractive to potential customers. This utility can be created whenever a client is handed the keys to their new car, simply because from that moment they are free to do whatever they want to do with it. A car manufacturing company could sell all the parts of their cars separately. However, by assembling the parts (and manufacturing cars), this company adds significant value for their customers. During COVID, countless companies repositioned their products and added distribution channels to reach customers at their homes. Observing the economic, public health, and market changes helped these companies make the right choices to remain competitive throughout the pandemic. In the face of government shutdowns, for example, Airbnb added online services to its business model. And Peloton quickly pivoted to remote work, allowing it to take advantage of an expanded labor market. This is an example of which value dimension? Quality Cost Agility Delivery Chrysler offers a five-year, 50,000 mile warranty; Whirlpool Corporation promises that parts for all models will be available for 15 years; Hewlett-Packard gives customers a 99% uptime service guarantee on its computers; and Mercedes-Benz makes technicians available for roadside assistance after normal dealer service hours. What value dimension is each of these companies' focus? Cost Delivery Agility Quality 5 Companies introducing a new product often cite its cost advantages. If Company X produces a coffee maker virtually identical to that of Company Y, Company X may offer a version at a lower cost. If it comes with a reusable filter, the savings on paper filters are highlighted in packaging and advertising. These are examples of companies doing which of the following? Differentiating your product Avoiding disqualification Creating tradeoffs and synergies Getting into the game A seat belt manufacturer estimates the demand for replacement seat belts and then creates a plan to manufacture those seat belts over a period of time. Once replacement seat belts start to roll off the production line, they are packaged into boxes (for the purposes of this example, let's assume 100 replacement seat belts per box) and sent to distributors in priority order of where it is anticipated the highest demand will be. These distributors then send the replacement seat belts to the car dealerships, who hold several in stock so that when a customer comes in requiring a replacement seat belt, they are able to replace it within a short period of time and the customer is happy. Is this manufacturer using a push or a pull system? What could be a potential issue with this system? Push system; it creates unneeded inventory throughout the system-manufacturer, distributor, and dealership. Pull system; it creates unneeded inventory throughout the system-manufacturer, distributor, and dealership. Pull system; it is unable to make rapid responses to changes in demand. Push system: it is able to make rapid responses to changes in demand. Apple's chief executive officer (CEO) Tim Cook parlayed the 16 years of supply management experience he gained working at IBM and Compaq Computers to entirely revamp Apple's manufacturing process. Starting as Apple's chief operating officer (COO) in 1998, Cook pulled the company out of manufacturing, closing Apple's warehouses and factories around the world. He opted instead to establish relationships with independent manufacturing contractors, many of them located in China where labor and cost of goods were much cheaper. These manufacturers would deliver products as needed. Cook credits these changes as a key factor in Apple's growth and profitability. What system is Cook using and why would it increase profitability for Apple? Just-in-time: Cook's supply chain improvements reduced the amount of time Apple's inventory sat on the company's balance sheet. Batch system; Cooks changes produced small quantities of output that greatly varied from one batch to the next. Continuous system: Cook's supply chain processed flow through a series of steps or operations. Automation; Cook's changes kept costs of production within reasonable levels. 8 The other day, I ordered a taco at the local taqueria. I specifically asked for no guacamole because I really hate guacamole. Sadly, someone wasn't paying attention, so my taco arrived fully guacamole laden. When I pointed out the error, the server tossed the taco in the garbage and set the cook to work on a netv one. This is a perfect example of which form of waste? How can this be avoided? Over-production; calculate and control inventory days on hand Defects: track mistakes and correct behavior Inventory: start a waste journal Motion; adopt the FIFO method Waste of motion refers to movement of people, resources, or machinery. For example, multiple staff may be operating one machine when only one person is necessary, resulting in time and resource wastage. These inefficiencies can also be dangerous and lead to workplace injuries and delay production. Waste of motion doesn't always have to be on a large scale. Small-scale waste of motion includes things like rummaging through a pile of materials to find the right component, walking to the printer across the warehouse, or even sifting through sheets of paper. What is the key to reducing motion waste and what is a possible solution? Inventory software can help waste by tracking and recording all key changes related to demand and sales trends. Assess your workflows and layout to identify areas of waste and create a workflow process document to ensure staff follow steps to reduce unplanned movement. Automate pick lists that can be sent to mobile devices so your warehouse team doesn't have to keep picking up paper orders. Monitor the quality of defects and create waste audits to regularly find where defects arise. Joseph has a kiwifruit orchard, and he has all the required factors of production: land, vines, workers, fertilizer, and water. He has decided how much of each input he will need, but he hasn't yet decided how much fertilizer he will use. Joseph knows that if he increases the amount of fertilizer, the output of kiwifruit will increase. However, it may reach a point where too much fertilizer will poison the plant and decrease his output. The law of diminishing returns states that there will be a point where the additional output of kiwifruit gained from one additional unit of fertilizer will be less than the additional output of kiwifruit from the previous increase in fertilizer. This table shows the output of kiwifruit per unit of fertilizer: At which point does adding one additional unit of fertilizer hit the law of diminishing returns? Between 1 and 2 Between 2 and 3 Between 3 and 4 The iPhone has become a ubiquitous accessory around the world and changed the way we communicate, connect, create, and much more. The company continues to be a disruptor and pace-setter that competitors are constantly chasing. This is an example of what type of innovation? Adjacent innovation Incremental innovation Breakthrough innovation Transformational innovation Instead of putting customers on hold, JetBlue's call-in customer service system now takes their number and calls them back later. This small upgrade effectively addressed an immediate problem of phone call wait times and provided a new level of convenience for JetBlue customers and employees alike. This is an example of what type of innovation? Adjacent innovation Breakthrough innovation Transformational innovation incremental innovation 13 Beth has dreams of opening a gourmet cupcake store. She does a break-even analysis to determine how many cupcakes she'll have to sell to break even on her investment. She's done the math, so she knows her fixed costs for one year are $10,000 and her variable cost per unit is $0.50. She's done a competitor study and some other calculations and determined her unit price to be $6.00. $10,000/($6$0.50)=1,819 cupcakes that Beth must sell in one year to break even What is the limitation of this analysis? That break-even analysis does not consider market demand. The contribution margin is the difference (more than zero) between the product's selling price and its total variable cost. This margin contributes to offsetting fixed costs. Fixed costs are those that remain the same no matter how much product or service is sold, Kellogg's has revamped their whole end-to-end innovation capability to focus on the core food design skills: investing in culinary to get closer to the real food experience; sensory, to equitably learn with the consumer; a design studio and rapid process lab to speed up the prototyping; a scaled-up pilot, which is now certified to make salable food; and finally, a Menuvation Center at The Hatchery in Chicago to showcase the foods with partners and customers. Why is this end-to end product development process effective? The team leaves a trail of learnings for the next team. This process limits meddling by management. It allows the company to hit trends, influence new trends, and grow the business. Each product has an elaborate product launch plan that is held in strict secrecy

Step by Step Solution

There are 3 Steps involved in it

Step: 1

Get Instant Access to Expert-Tailored Solutions

See step-by-step solutions with expert insights and AI powered tools for academic success

Step: 2

Step: 3

Ace Your Homework with AI

Get the answers you need in no time with our AI-driven, step-by-step assistance

Get Started