Answered step by step

Verified Expert Solution

Question

1 Approved Answer

Product Yield at Continental Luggage Company The Continental Luggage Company manufactures several different styles of soft- and hardcover luggage, briefcases, hanging bags, and purses. Its

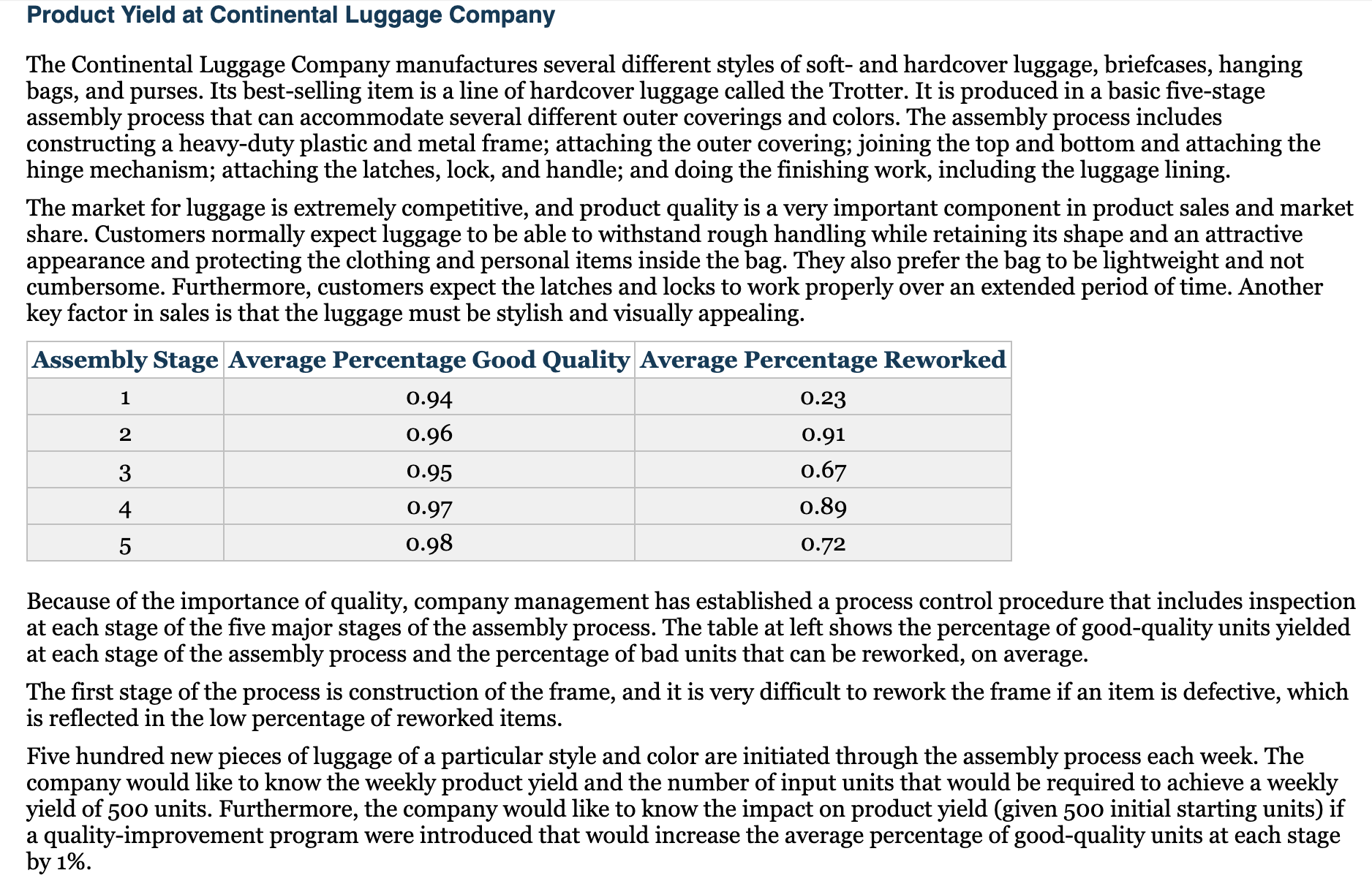

Product Yield at Continental Luggage Company The Continental Luggage Company manufactures several different styles of soft- and hardcover luggage, briefcases, hanging bags, and purses. Its best-selling item is a line of hardcover luggage called the Trotter. It is produced in a basic five-stage assembly process that can accommodate several different outer coverings and colors. The assembly process includes constructing a heavy-duty plastic and metal frame; attaching the outer covering; joining the top and bottom and attaching the hinge mechanism; attaching the latches, lock, and handle; and doing the finishing work, including the luggage lining. The market for luggage is extremely competitive, and product quality is a very important component in product sales and market share. Customers normally expect luggage to be able to withstand rough handling while retaining its shape and an attractive appearance and protecting the clothing and personal items inside the bag. They also prefer the bag to be lightweight and not cumbersome. Furthermore, customers expect the latches and locks to work properly over an extended period of time. Another key factor in sales is that the luggage must be stylish and visually appealing. Because of the importance of quality, company management has established a process control procedure that includes inspection at each stage of the five major stages of the assembly process. The table at left shows the percentage of good-quality units yielded at each stage of the assembly process and the percentage of bad units that can be reworked, on average. The first stage of the process is construction of the frame, and it is very difficult to rework the frame if an item is defective, which is reflected in the low percentage of reworked items. Five hundred new pieces of luggage of a particular style and color are initiated through the assembly process each week. The company would like to know the weekly product yield and the number of input units that would be required to achieve a weekly yield of 500 units. Furthermore, the company would like to know the impact on product yield (given 500 initial starting units) if a quality-improvement program were introduced that would increase the average percentage of good-quality units at each stage by 1%

Product Yield at Continental Luggage Company The Continental Luggage Company manufactures several different styles of soft- and hardcover luggage, briefcases, hanging bags, and purses. Its best-selling item is a line of hardcover luggage called the Trotter. It is produced in a basic five-stage assembly process that can accommodate several different outer coverings and colors. The assembly process includes constructing a heavy-duty plastic and metal frame; attaching the outer covering; joining the top and bottom and attaching the hinge mechanism; attaching the latches, lock, and handle; and doing the finishing work, including the luggage lining. The market for luggage is extremely competitive, and product quality is a very important component in product sales and market share. Customers normally expect luggage to be able to withstand rough handling while retaining its shape and an attractive appearance and protecting the clothing and personal items inside the bag. They also prefer the bag to be lightweight and not cumbersome. Furthermore, customers expect the latches and locks to work properly over an extended period of time. Another key factor in sales is that the luggage must be stylish and visually appealing. Because of the importance of quality, company management has established a process control procedure that includes inspection at each stage of the five major stages of the assembly process. The table at left shows the percentage of good-quality units yielded at each stage of the assembly process and the percentage of bad units that can be reworked, on average. The first stage of the process is construction of the frame, and it is very difficult to rework the frame if an item is defective, which is reflected in the low percentage of reworked items. Five hundred new pieces of luggage of a particular style and color are initiated through the assembly process each week. The company would like to know the weekly product yield and the number of input units that would be required to achieve a weekly yield of 500 units. Furthermore, the company would like to know the impact on product yield (given 500 initial starting units) if a quality-improvement program were introduced that would increase the average percentage of good-quality units at each stage by 1% Step by Step Solution

There are 3 Steps involved in it

Step: 1

Get Instant Access to Expert-Tailored Solutions

See step-by-step solutions with expert insights and AI powered tools for academic success

Step: 2

Step: 3

Ace Your Homework with AI

Get the answers you need in no time with our AI-driven, step-by-step assistance

Get Started