Answered step by step

Verified Expert Solution

Question

1 Approved Answer

Production Planning for BKBC Nick works as a production planner for BKBC. BKBC manufactures products A and B using raw materials E and F. 2

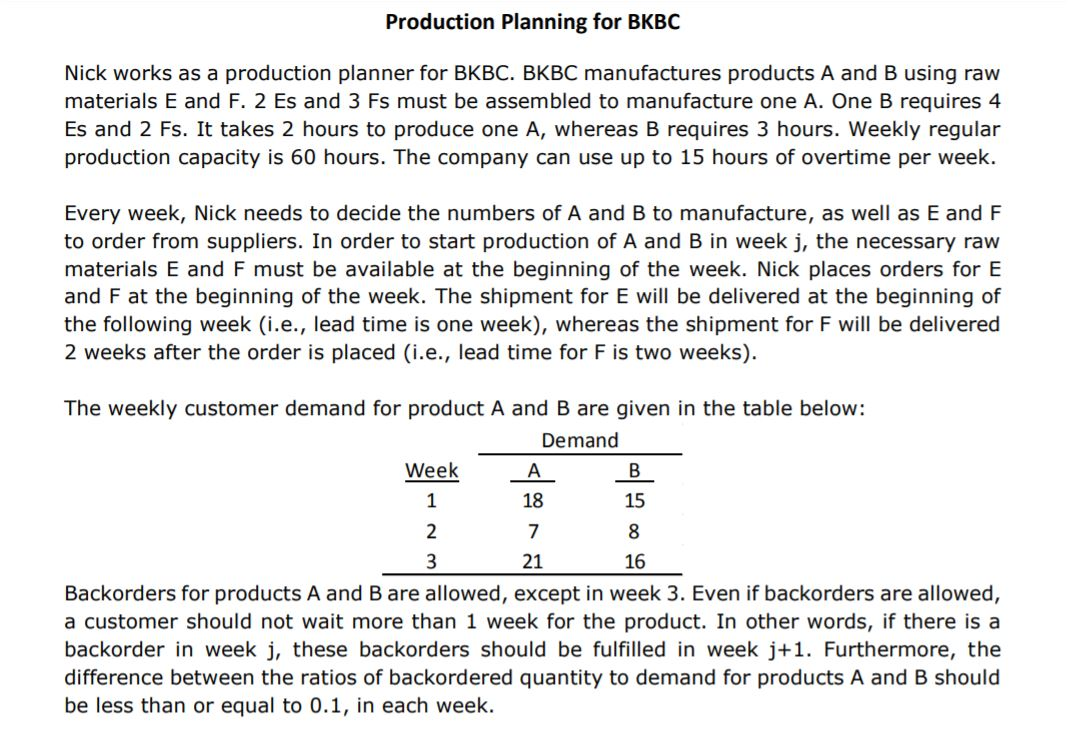

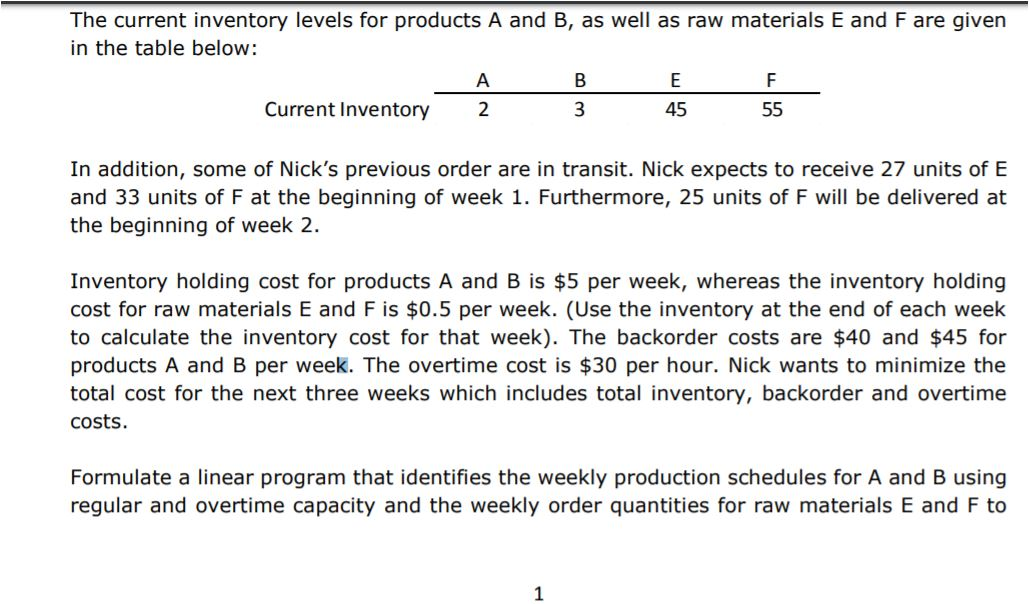

Production Planning for BKBC Nick works as a production planner for BKBC. BKBC manufactures products A and B using raw materials E and F. 2 Es and 3 Fs must be assembled to manufacture one A. One B requires 4 Es and 2 Fs. It takes 2 hours to produce one A, whereas B requires 3 hours. Weekly regular production capacity is 60 hours. The company can use up to 15 hours of overtime per week. Every week, Nick needs to decide the numbers of A and B to manufacture, as well as E and F to order from suppliers. In order to start production of A and B in week j, the necessary raw materials E and F must be available at the beginning of the week. Nick places orders for E and F at the beginning of the week. The shipment for E will be delivered at the beginning of the following week (i.e., lead time is one week), whereas the shipment for F will be delivered 2 weeks after the order is placed (i.e., lead time for F is two weeks) The weekly customer demand for product A and B are given in the table below: Demand Week A B 1 18 15 2 7 3 21 16 Backorders for products A and B are allowed, except in week 3. Even if backorders are allowed, a customer should not wait more than 1 week for the product. In other words, if there is a backorder in week j, these backorders should be fulfilled in week j+1. Furthermore, the difference between the ratios of backordered quantity to demand for products A and B should be less than or equal to 0.1, in each week. The current inventory levels for products A and B, as well as raw materials E and F are given in the table below: A B E P Current Inventory 2 3 45 55 In addition, some of Nick's previous order are in transit. Nick expects to receive 27 units of E and 33 units of F at the beginning of week 1. Furthermore, 25 units of F will be delivered at the beginning of week 2. Inventory holding cost for products A and B is $5 per week, whereas the inventory holding cost for raw materials E and F is $0.5 per week. (Use the inventory at the end of each week to calculate the inventory cost for that week). The backorder costs are $40 and $45 for products A and B per week. The overtime cost is $30 per hour. Nick wants to minimize the total cost for the next three weeks which includes total inventory, backorder and overtime costs. Formulate a linear program that identifies the weekly production schedules for A and B using regular and overtime capacity and the weekly order quantities for raw materials E and F to 1 minimize the total cost. Define the decision variables (explicitly state what they represent), formulate the objective function and constraints. Production Planning for BKBC Nick works as a production planner for BKBC. BKBC manufactures products A and B using raw materials E and F. 2 Es and 3 Fs must be assembled to manufacture one A. One B requires 4 Es and 2 Fs. It takes 2 hours to produce one A, whereas B requires 3 hours. Weekly regular production capacity is 60 hours. The company can use up to 15 hours of overtime per week. Every week, Nick needs to decide the numbers of A and B to manufacture, as well as E and F to order from suppliers. In order to start production of A and B in week j, the necessary raw materials E and F must be available at the beginning of the week. Nick places orders for E and F at the beginning of the week. The shipment for E will be delivered at the beginning of the following week (i.e., lead time is one week), whereas the shipment for F will be delivered 2 weeks after the order is placed (i.e., lead time for F is two weeks) The weekly customer demand for product A and B are given in the table below: Demand Week A B 1 18 15 2 7 3 21 16 Backorders for products A and B are allowed, except in week 3. Even if backorders are allowed, a customer should not wait more than 1 week for the product. In other words, if there is a backorder in week j, these backorders should be fulfilled in week j+1. Furthermore, the difference between the ratios of backordered quantity to demand for products A and B should be less than or equal to 0.1, in each week. The current inventory levels for products A and B, as well as raw materials E and F are given in the table below: A B E P Current Inventory 2 3 45 55 In addition, some of Nick's previous order are in transit. Nick expects to receive 27 units of E and 33 units of F at the beginning of week 1. Furthermore, 25 units of F will be delivered at the beginning of week 2. Inventory holding cost for products A and B is $5 per week, whereas the inventory holding cost for raw materials E and F is $0.5 per week. (Use the inventory at the end of each week to calculate the inventory cost for that week). The backorder costs are $40 and $45 for products A and B per week. The overtime cost is $30 per hour. Nick wants to minimize the total cost for the next three weeks which includes total inventory, backorder and overtime costs. Formulate a linear program that identifies the weekly production schedules for A and B using regular and overtime capacity and the weekly order quantities for raw materials E and F to 1 minimize the total cost. Define the decision variables (explicitly state what they represent), formulate the objective function and constraints

Step by Step Solution

There are 3 Steps involved in it

Step: 1

Get Instant Access to Expert-Tailored Solutions

See step-by-step solutions with expert insights and AI powered tools for academic success

Step: 2

Step: 3

Ace Your Homework with AI

Get the answers you need in no time with our AI-driven, step-by-step assistance

Get Started