Answered step by step

Verified Expert Solution

Question

1 Approved Answer

Project 1: In the first project, you have been asked to work on some design problems and technically support the team working on casting

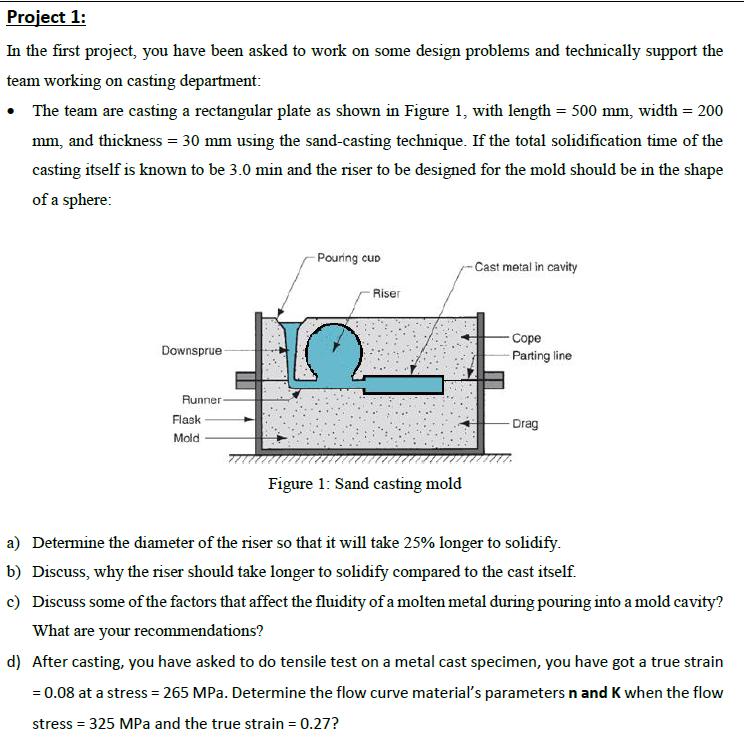

Project 1: In the first project, you have been asked to work on some design problems and technically support the team working on casting department: The team are casting a rectangular plate as shown in Figure 1, with length = 500 mm, width = 200 mm, and thickness = 30 mm using the sand-casting technique. If the total solidification time of the casting itself is known to be 3.0 min and the riser to be designed for the mold should be in the shape of a sphere: Pouring cup Cast metal in cavity Riser Cope Downsprue Parting line Runner- Flask - Drag Mold Figure 1: Sand casting mold a) Determine the diameter of the riser so that it will take 25% longer to solidify. b) Discuss, why the riser should take longer to solidify compared to the cast itself. c) Discuss some of the factors that affect the fluidity of a molten metal during pouring into a mold cavity? What are your recommendations? d) After casting, you have asked to do tensile test on a metal cast specimen, you have got a true strain = 0.08 at a stress = 265 MPa. Determine the flow curve material's parameters n and K when the flow stress = 325 MPa and the true strain = 0.27?

Step by Step Solution

★★★★★

3.47 Rating (157 Votes )

There are 3 Steps involved in it

Step: 1

Get Instant Access to Expert-Tailored Solutions

See step-by-step solutions with expert insights and AI powered tools for academic success

Step: 2

Step: 3

Ace Your Homework with AI

Get the answers you need in no time with our AI-driven, step-by-step assistance

Get Started