Question

PT GUNS N DAM (PT. GUNDAM) has rapidly become one of the most innovative agri-based companies in Indonesia. Established only in 2010, the company started

PT GUNS N DAM (PT. GUNDAM) has rapidly become one of the most innovative agri-based companies in Indonesia. Established only in 2010, the company started out from the acquisition of an old run-down medium sized palm oil plantation located in remote part of West Sulawesi. Immediately aware of the need to differentiate and distance itself from the negative image of the palm oil industry and the adverse environmental impact it creates; the management of PT. GUNDAM made it a mission and strategic commitment to follow sustainable palm oil production program. This core value continues to be in focus throughout their business development and operations. The successfully implement a full and comprehensive range of policies, initiatives and action plans, all of which are complying to the highest level of business, social ethics as well as environmental practices and standards. The condition has reflected positively, gaining excellence in all core aspects of the companys business metrics for performance and growth. Within the short 10-year period, besides completing a full turnaround of its business, the company also greatly expanded its presence.

Starting from only owning a single palm oil plantation business, it has now become a fully diversified and integrated agri-based industrial entity. Its business now ranges from research & development, oil palm seed breeding, oil palm cultivation and milling, and include downstream business refining, branding and marketing of cooking oil, margarine, shortening and other palm oil derivative products. Worthy appreciation has been obtained from all stakeholders including positive acknowledgment from major consumers and environmental advocacy groups which are usually very critical to the palm oil industry.

Recent developments in global trade relationship, ecological and environmental dynamics as well as the devastation of health and social economic conditions caused by ongoing COVID19 pandemic has put extreme pressure to PT. GUNDAM business. The landscape of the economy and business environment has tremendously changed within a single year of 2020. Such unpredictable and extreme conditions had required the companys management team to immediately reassess the companys entire business strategy. As leading innovator in the industry, it has decided to leverage its capability to further advance into the green energy business sphere to drive its future growth and fully adapting to the new normal.

In line with its focus to resolve the environmental issues PT. GUNDAM is exploring further business prospects, and to specifically participate in the Indonesian governments program for renewable energy development. The company sees a great opportunity to enter green energy business and reinforce the companys eco-management capabilities, to effectively reduce its environmental impact and increase its operating efficiency.

Benefiting from its extensive reach and networking not only within the industry, but also the environmental and scientific communities both local and international levels, the Research and Development unit PT. GUNDAM had obtained a great breakthrough. As recognition, the company have recently received support and financial sponsorship from the International Green Energy Consortium (IGEC) to host two important Pilot Projects on the use of new technologies in the form of independent Renewable Energy Project Grant.

PT. GUNDAM management is greatly honored to receive the support and endorsement, indicating that the Pilot Projects will be attached to two of company Plantation optimizing projects in Sulawesi, namely at Project A at the Manorang Hijau Plantation (MRHP) and Project B the Maniang Hijau Plantation (MIHP).

Scope of these two technologies is further detailed below introductory profiles to be used only for illustrative purposes.

Project A: Manorang Hijau Plantation (MRHP) Plantation Optimization

Project A Manorang Hijau Plantation (MRHP) will implement Plantation Optimization program, this is to immediately overhaul the machinery and increase the production capacity of the CPO mill from the current maximum daily processing capacity of 300 tons of Palm Oil Fresh Fruit Branch (FFB). This increase in production capacity is in line with the projected rise of FFB for the next 10 years, in parallel with corresponding age profile of the maturing oil palm trees within their plantation. Yield of the FFBs from these plants is expected to rise annually by 5 pct.

The local management team has reported to Operations director at PT. GUNDAM head office relating to concerns in condition of the plants machineries. Based on the original built specification, the entire set CPO milling system machinery has an economic life of 5 years. Actual processing capacity of the current CPO mill has been significantly reduced due to damage in the primary steam boilers at the plant. This was caused by uncontrolled mineral deposits and had gradually restricts the flow of the heated steam to the sterilization chambers. Several attempts to repair the equipment has been done but due to the limited availability of the customized spare parts needed, being purchase only 3 years ago.

Because of the above technical factors, in the current production year has been constrained. The plant can only be safely operated at daily load of 300 tons FFB per day. For the next three years, the technical team expects that this capacity will need to be gradually reduced by 6 percent each year. The Technical Support team from Head Office had confirmed these findings, and from joint discussion with external Technical Consulting team and Vendors further validated that from the initial purchase price of IDR 25 billion, if they are sold presently the company get no more than IDR 400 million for the entire equipment at the plant. The current machine has no market value at the end of its economic live.

PT. GUNDAM had anticipated these conditions early last year and already commissioned the same technical team to prepare alternative plan to invest in new equipment and machinery for MRHP. This has been based on maximum daily FFB processing capacity of 350 tons and facilitate the increase of 5% per year for the next 5 years.

After final negotiation with the suppliers and contractors PT. GUNDAM procurement team received best quote through tender of IDR 40 billion base cost of the total replacement machinery and related hardware. Under the Turn-key project basis, additional 12 percent will be charged for the technical design, construction, installation and commission services; until ready for handover and production run to MRHP Production team at site. After the project ended, the team expected the market value of the proposed machines null.

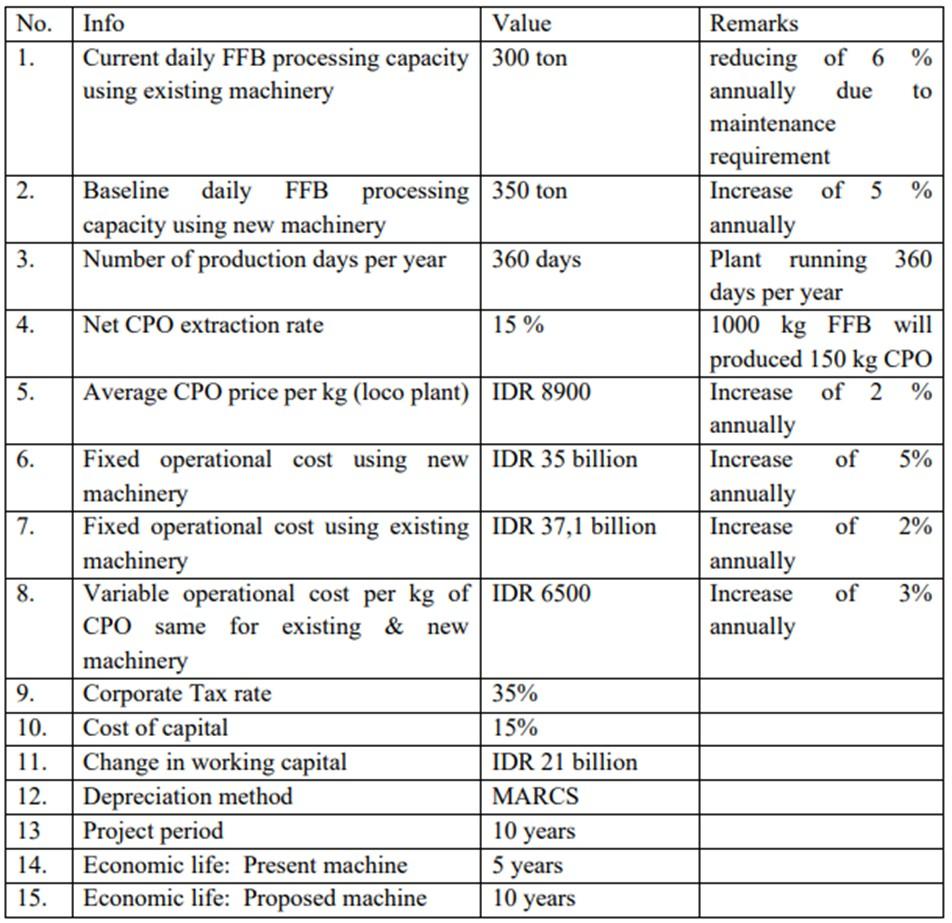

In order to complete the capital budgeting process, the local management at MHRP has provided the following operational and financial figures as well as planning baselines : (in the picture)

iNSTURCTUION

You are assigned to evaluate purely the aspects which are linked directly to PT. GUNDAM own internal investment funds of their Core Project Scope of their Plantation Optimization projects at either the Manorang Hijau Plantation (MRHP)

REQUIRE:

PT. GUNDAM management brought in the marketing, production management, procurement, capital investment, and accounting department to formulate estimates of the initial cost of the expansion, as well as future cash flow that can be used to evaluate this expansion.

a. Should PT. GUNDAM replace the machines? Explain your reasoning. Provide complete analysis showing : initial investment, operating cash flows, terminal cash flow, as well as depreciation schedules, and using set of capital budgeting techniques

b. If PT. GUNDAMs cost of capital increases by 5 percent, would your recommendation change?

c. At what cost of capital, would your recommendation change? Indicate your decision on a net present value profile of this investment decision

No. 1. Info Value Current daily FFB processing capacity 300 ton using existing machinery 2. Baseline daily FFB processing | 350 ton capacity using new machinery Number of production days per year 360 days 3. 4. Net CPO extraction rate 15 % Remarks reducing of 6 % annually due to maintenance requirement Increase of 5 % annually Plant running 360 days per year 1000 kg FFB will produced 150 kg CPO Increase of 2 % annually Increase of 5% annually Increase of 2% annually Increase 3% annually 5. Average CPO price per kg (loco plant) IDR 8900 6. 7. 8. of Fixed operational cost using new IDR 35 billion machinery Fixed operational cost using existing IDR 37,1 billion machinery Variable operational cost per kg of IDR 6500 CPO same for existing & & new machinery Corporate Tax rate 35% Cost of capital 15% Change in working capital IDR 21 billion Depreciation method MARCS Project period Economic life: Present machine Economic life: Proposed machine 9. 10. 11. 12. 13 14. 15. 10 years 5 years 10 years No. 1. Info Value Current daily FFB processing capacity 300 ton using existing machinery 2. Baseline daily FFB processing | 350 ton capacity using new machinery Number of production days per year 360 days 3. 4. Net CPO extraction rate 15 % Remarks reducing of 6 % annually due to maintenance requirement Increase of 5 % annually Plant running 360 days per year 1000 kg FFB will produced 150 kg CPO Increase of 2 % annually Increase of 5% annually Increase of 2% annually Increase 3% annually 5. Average CPO price per kg (loco plant) IDR 8900 6. 7. 8. of Fixed operational cost using new IDR 35 billion machinery Fixed operational cost using existing IDR 37,1 billion machinery Variable operational cost per kg of IDR 6500 CPO same for existing & & new machinery Corporate Tax rate 35% Cost of capital 15% Change in working capital IDR 21 billion Depreciation method MARCS Project period Economic life: Present machine Economic life: Proposed machine 9. 10. 11. 12. 13 14. 15. 10 years 5 years 10 yearsStep by Step Solution

There are 3 Steps involved in it

Step: 1

Get Instant Access to Expert-Tailored Solutions

See step-by-step solutions with expert insights and AI powered tools for academic success

Step: 2

Step: 3

Ace Your Homework with AI

Get the answers you need in no time with our AI-driven, step-by-step assistance

Get Started