Q1:

Q2:

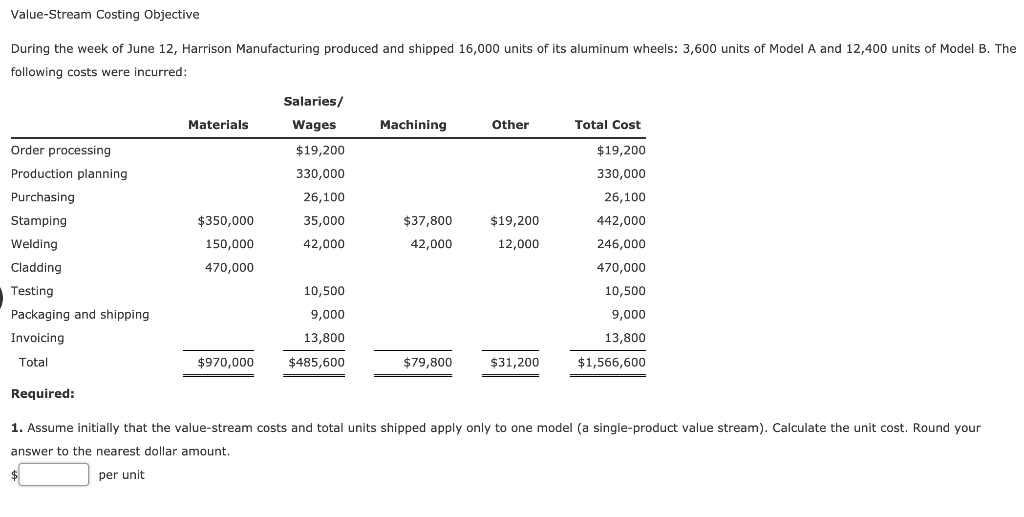

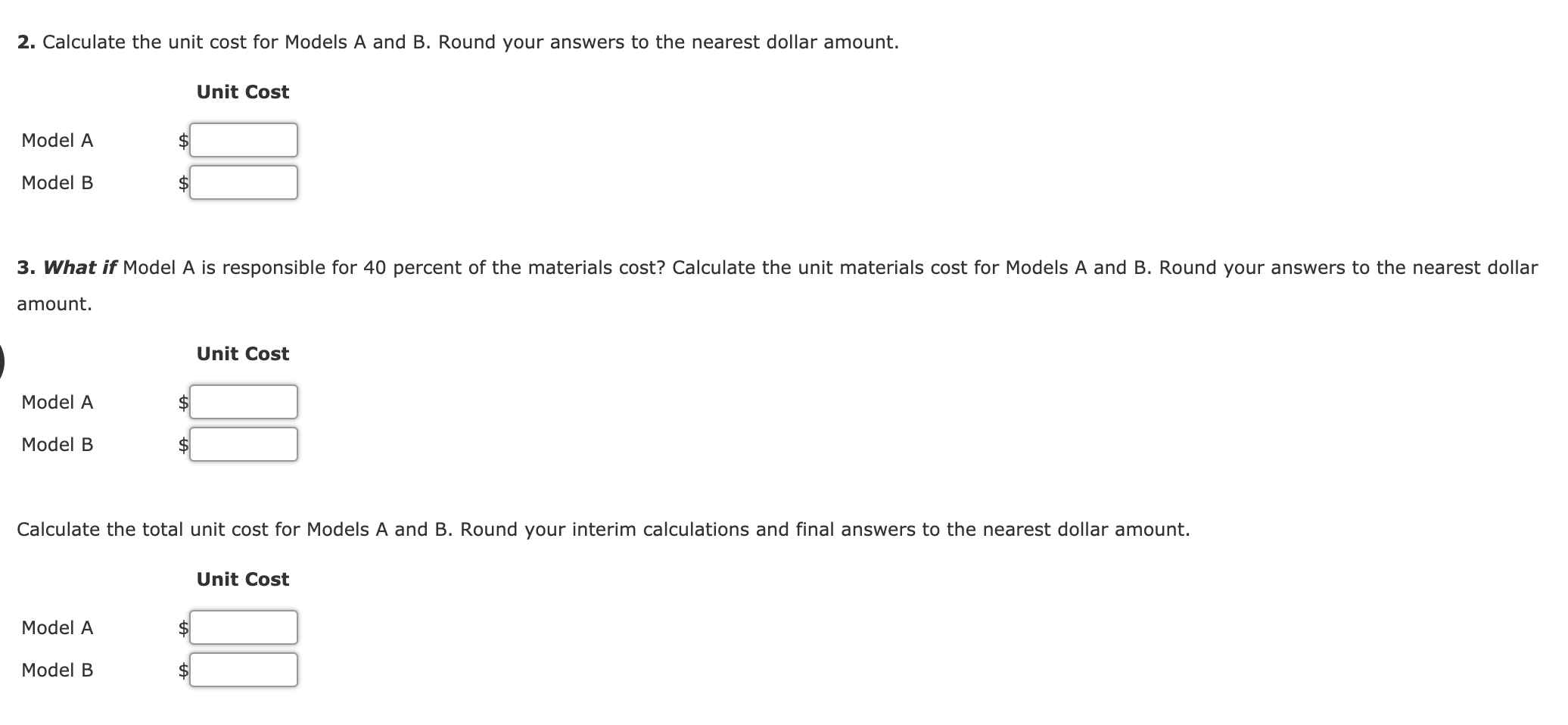

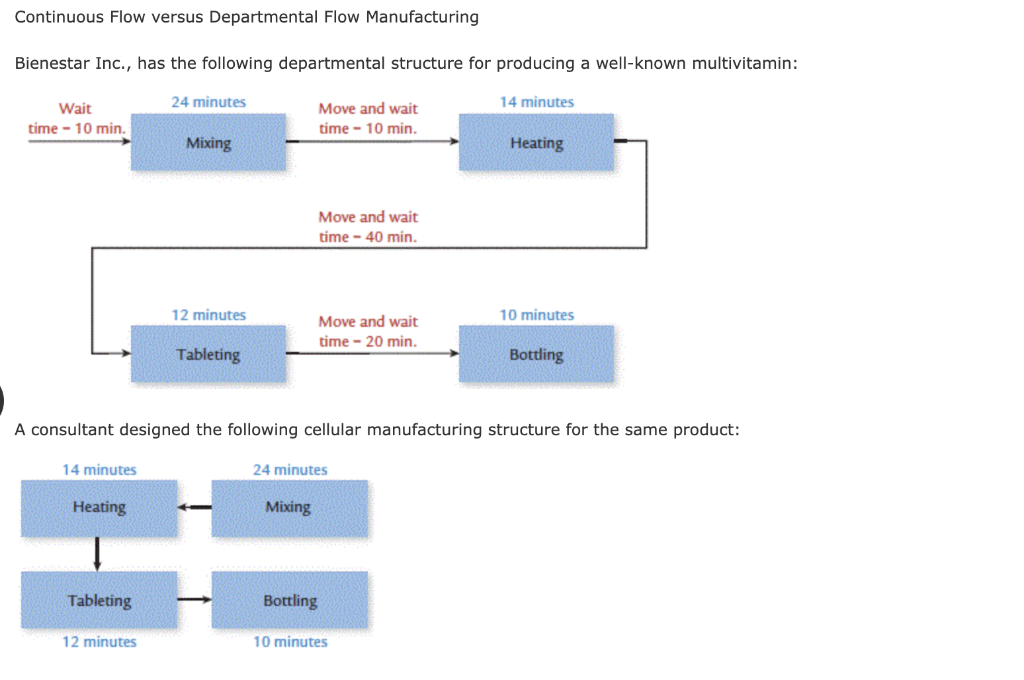

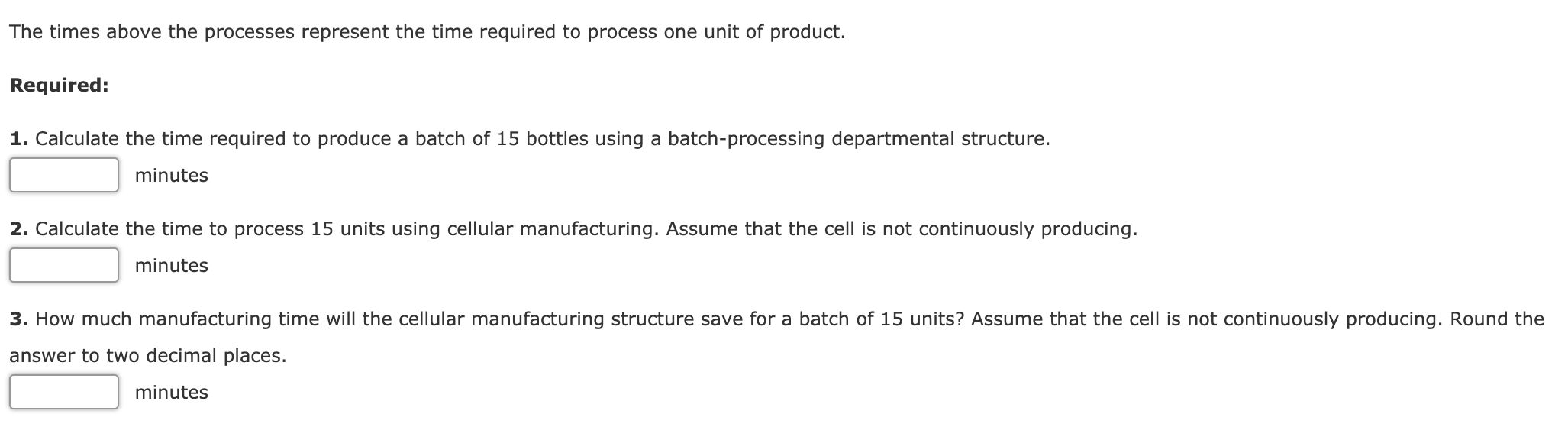

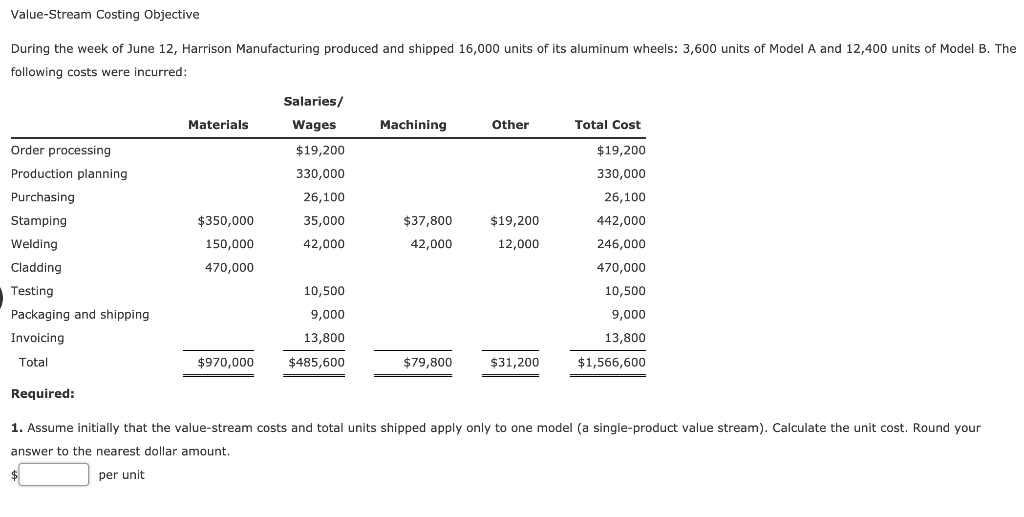

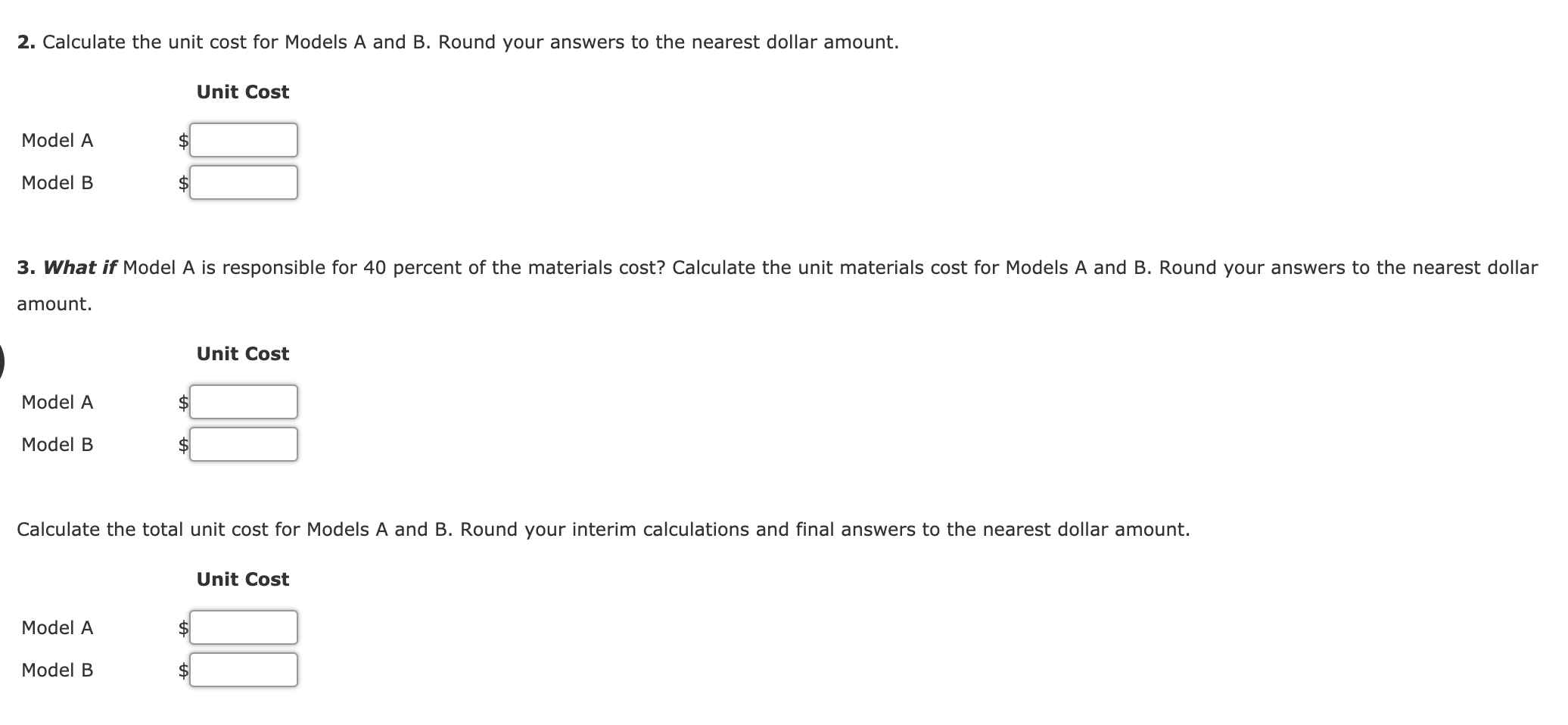

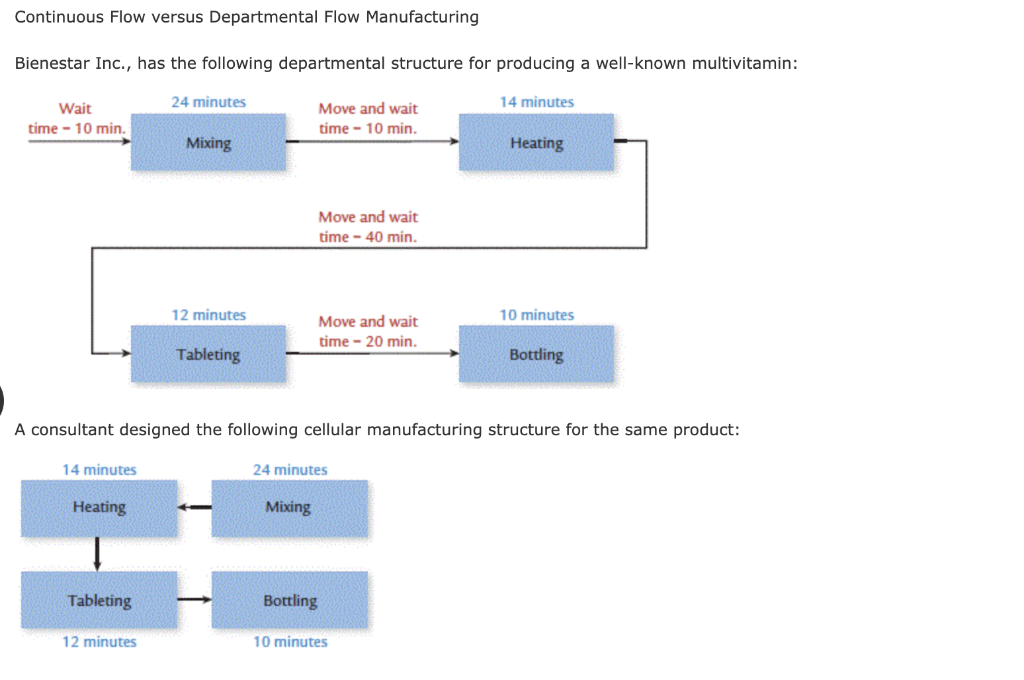

Value-Stream Costing Objective During the week of June 12, Harrison Manufacturing produced and shipped 16,000 units of its aluminum wheels: 3,600 units of Model A and 12,400 units of Model B. The following costs were incurred: Materials Machining Other Total Cost $19,200 Order processing Production planning Salaries/ Wages $19,200 330,000 26,100 35,000 330,000 26,100 $350,000 150,000 470,000 $37,800 42,000 $19,200 12,000 Purchasing Stamping Welding Cladding Testing Packaging and shipping Invoicing 42,000 442,000 246,000 470,000 10,500 9,000 10,500 9,000 13,800 13,800 Total $970,000 $485,600 $79,800 $31,200 $1,566,600 Required: 1. Assume initially that the value-stream costs and total units shipped apply only to one model (a single-product value stream). Calculate the unit cost. Round your answer to the nearest dollar amount. per unit 2. Calculate the unit cost for Models A and B. Round your answers to the nearest dollar amount. Unit Cost Model A Model B 3. What if Model A is responsible for 40 percent of the materials cost? Calculate the unit materials cost for Models A and B. Round your answers to the nearest dollar amount. Unit Cost Model A Model B Calculate the total unit cost for Models A and B. Round your interim calculations and final answers to the nearest dollar amount. Unit Cost Model A Model B Continuous Flow versus Departmental Flow Manufacturing Bienestar Inc., has the following departmental structure for producing a well-known multivitamin: 24 minutes 14 minutes Wait time - 10 min. Move and wait time - 10 min. Mixing Heating Move and wait time - 40 min. 12 minutes 10 minutes Move and wait time-20 min. Tableting Bottling A consultant designed the following cellular manufacturing structure for the same product: 14 minutes 24 minutes Heating Mixing Tableting Bottling 12 minutes 10 minutes The times above the processes represent the time required to process one unit of product. Required: 1. Calculate the time required to produce a batch of 15 bottles using a batch-processing departmental structure. minutes 2. Calculate the time to process 15 units using cellular manufacturing. Assume that the cell is not continuously producing. minutes 3. How much manufacturing time will the cellular manufacturing structure save for a batch of 15 units? Assume that the cell is not continuously producing. Round the answer to two decimal places. minutes