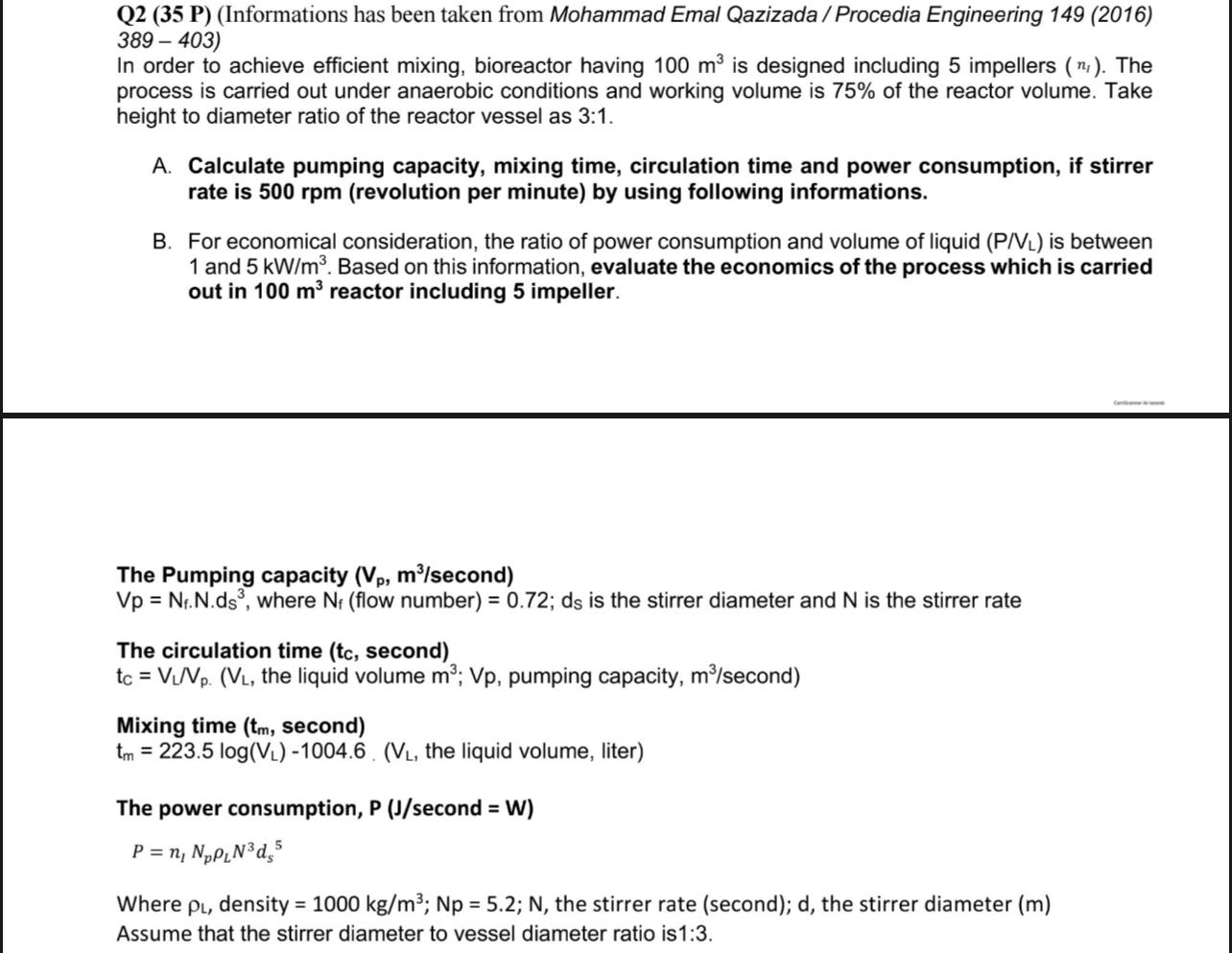

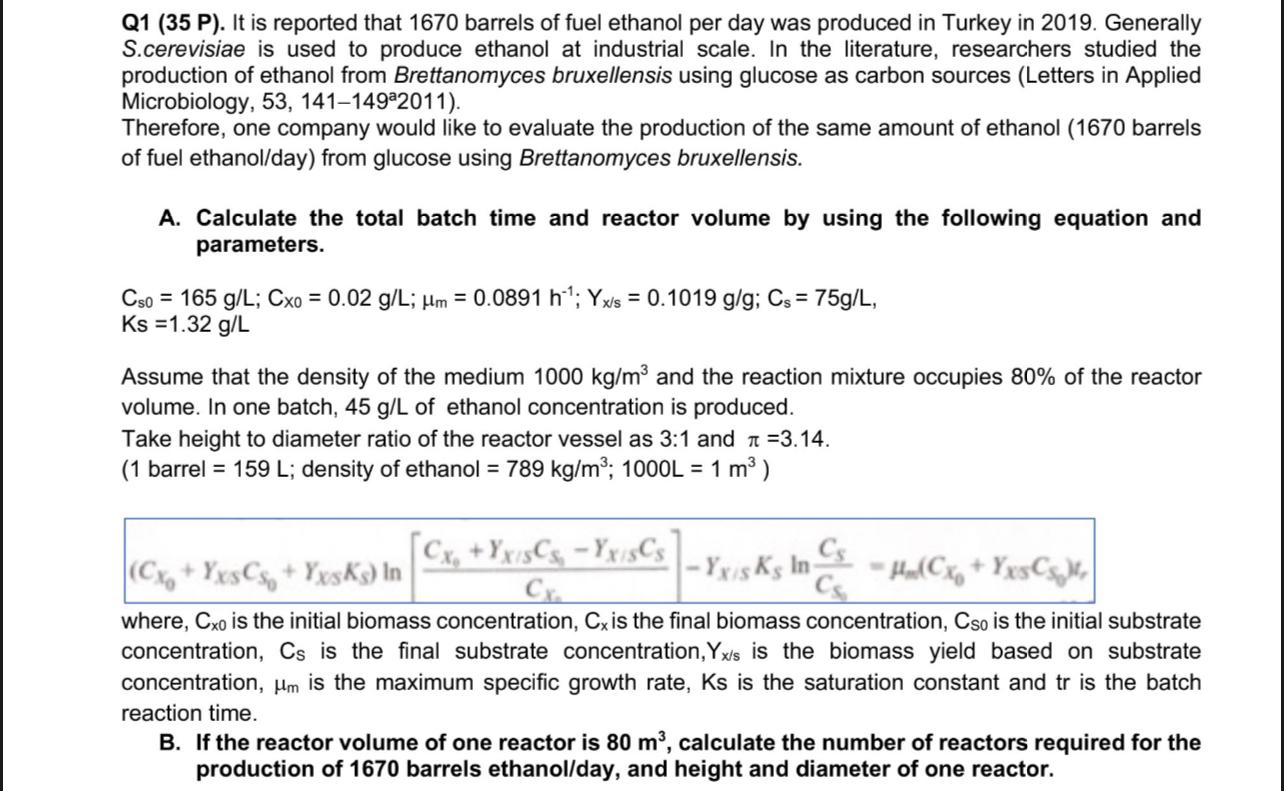

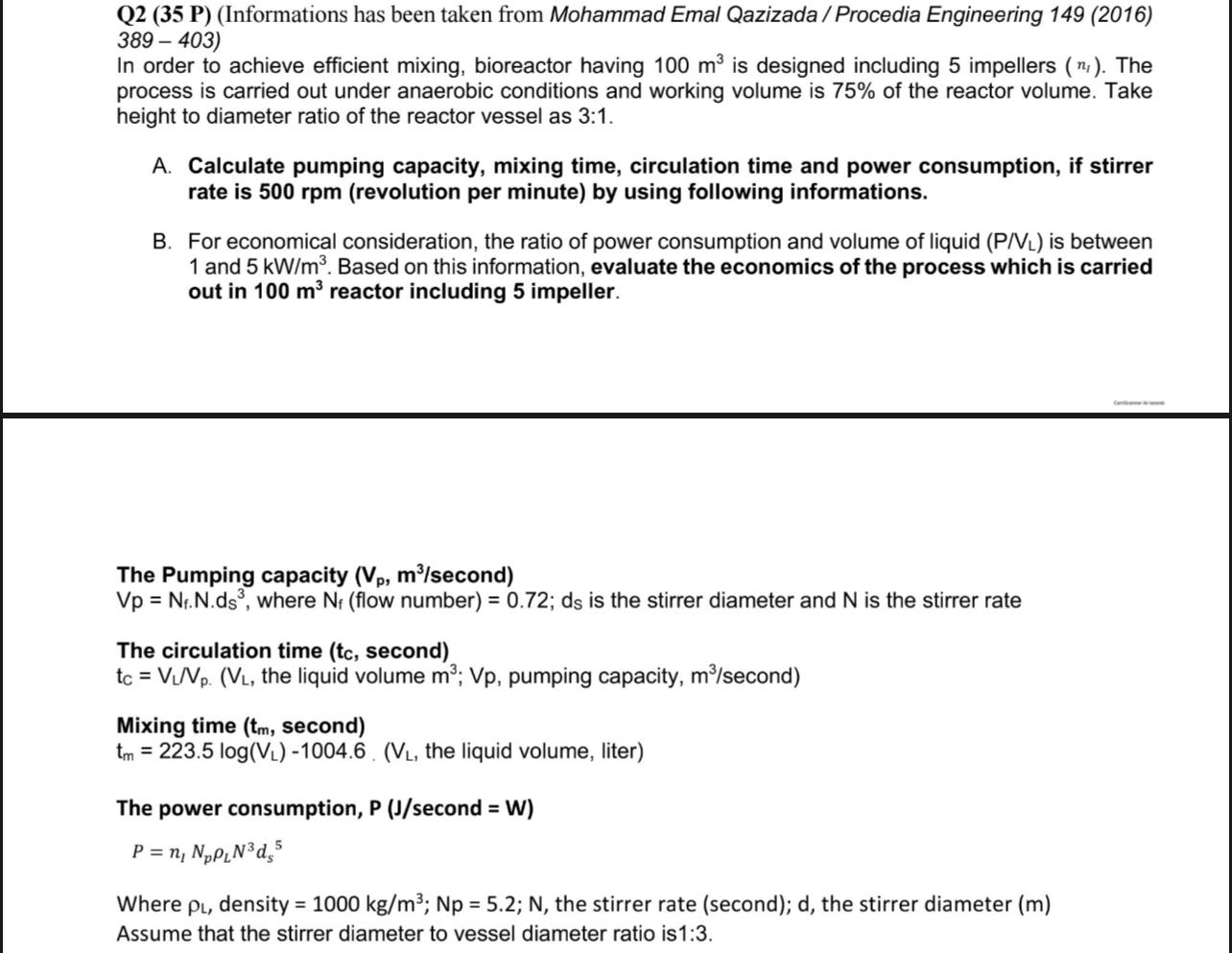

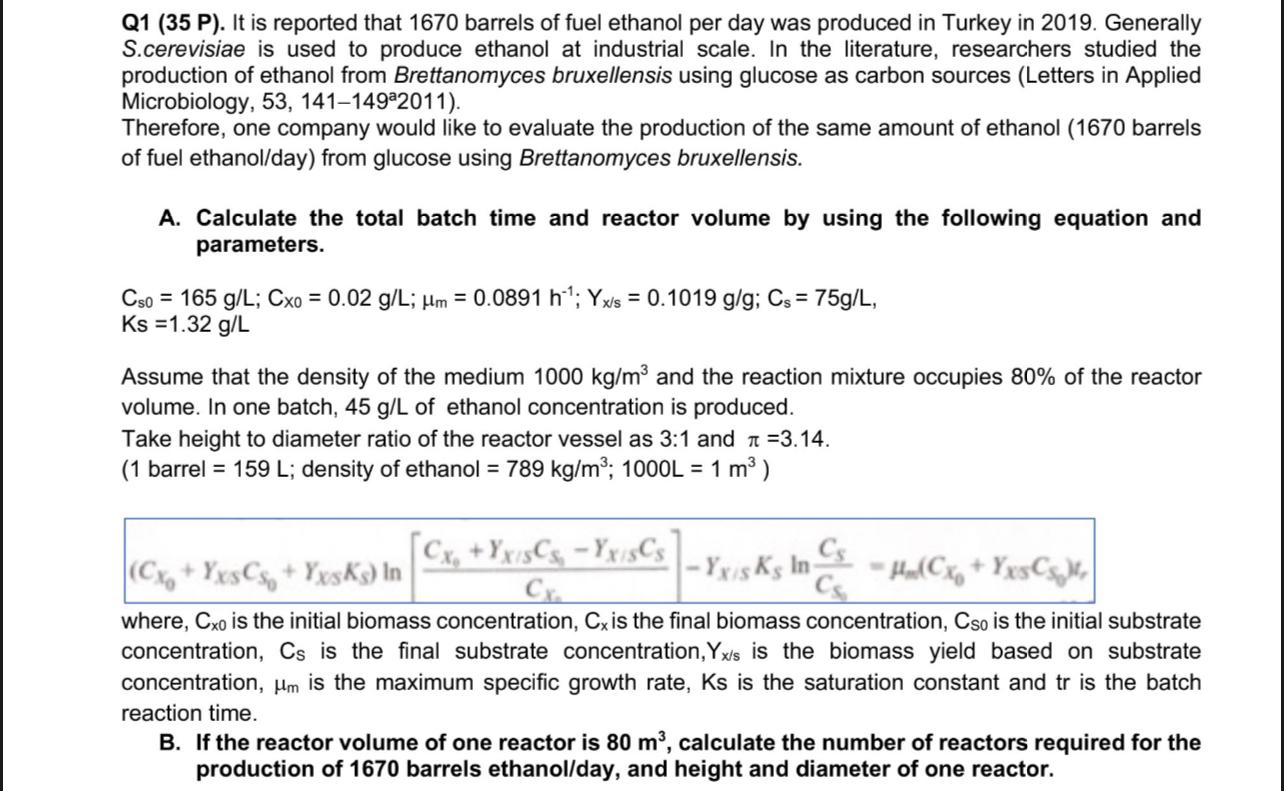

Q2 (35 P) (Informations has been taken from Mohammad Emal Qazizada / Procedia Engineering 149 (2016) 389403) In order to achieve efficient mixing, bioreactor having 100m3 is designed including 5 impellers (nl). The process is carried out under anaerobic conditions and working volume is 75% of the reactor volume. Take height to diameter ratio of the reactor vessel as 3:1. A. Calculate pumping capacity, mixing time, circulation time and power consumption, if stirrer rate is 500rpm (revolution per minute) by using following informations. B. For economical consideration, the ratio of power consumption and volume of liquid (P/VL) is between 1 and 5kW/m3. Based on this information, evaluate the economics of the process which is carried out in 100m3 reactor including 5 impeller. The Pumping capacity (Vp,m3/ second ) Vp=Nf.N.ds3, where Nf (flow number) =0.72;ds is the stirrer diameter and N is the stirrer rate The circulation time (t tc, second) tC=VL/Vp.(VL, the liquid volume m3;Vp, pumping capacity, m3/ second ) Mixing time (tm, second) tm=223.5log(VL)1004.6. (VL, the liquid volume, liter ) The power consumption, P(J/ second =W) P=nlNpLN3ds5 Where L, density =1000kg/m3;Np=5.2;N, the stirrer rate (second); d, the stirrer diameter (m) Assume that the stirrer diameter to vessel diameter ratio is 1:3. Q1 (35 P). It is reported that 1670 barrels of fuel ethanol per day was produced in Turkey in 2019. Generally S.cerevisiae is used to produce ethanol at industrial scale. In the literature, researchers studied the production of ethanol from Brettanomyces bruxellensis using glucose as carbon sources (Letters in Applied Microbiology, 53, 141-149a2011). Therefore, one company would like to evaluate the production of the same amount of ethanol (1670 barrels of fuel ethanol/day) from glucose using Brettanomyces bruxellensis. A. Calculate the total batch time and reactor volume by using the following equation and parameters. Cs0=165g/L;CX0=0.02g/L;m=0.0891h1;Yx/s=0.1019g/g;Cs=75g/LKs=1.32g/L Assume that the density of the medium 1000kg/m3 and the reaction mixture occupies 80% of the reactor volume. In one batch, 45g/L of ethanol concentration is produced. Take height to diameter ratio of the reactor vessel as 3:1 and =3.14. (1 barrel =159L; density of ethanol =789kg/m3;1000L=1m3 ) (CX0+YXSCS0+YXSKS)ln[CX0CX0+YX/SCS0YX/SCS]YX/SKSlnCSCS=m(CX0+YXSCS0)tt] where, Cx0 is the initial biomass concentration, Cx is the final biomass concentration, Cso is the initial substrate concentration, Cs is the final substrate concentration, Yx/s is the biomass yield based on substrate concentration, m is the maximum specific growth rate, Ks is the saturation constant and tr is the batch reaction time. B. If the reactor volume of one reactor is 80m3, calculate the number of reactors required for the production of 1670 barrels ethanol/day, and height and diameter of one reactor