Answered step by step

Verified Expert Solution

Question

1 Approved Answer

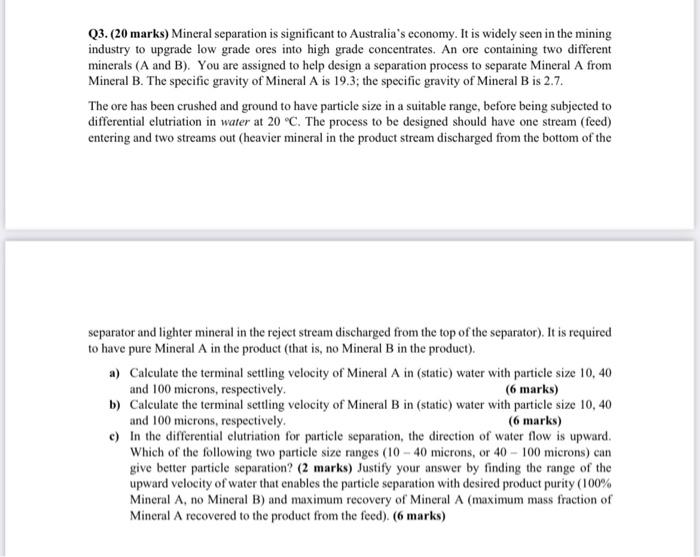

Q3. (20 marks) Mineral separation is significant to Australia's economy. It is widely seen in the mining industry to upgrade low grade ores into high

Q3. (20 marks) Mineral separation is significant to Australia's economy. It is widely seen in the mining industry to upgrade low grade ores into high grade concentrates. An ore containing two different minerals (A and B). You are assigned to help design a separation process to separate Mineral A from Mineral B. The specific gravity of Mineral A is 19.3; the specific gravity of Mineral B is 2.7. The ore has been crushed and ground to have particle size in a suitable range, before being subjected to differential elutriation in water at 20 C. The process to be designed should have one stream (feed) entering and two streams out (heavier mineral in the product stream discharged from the bottom of the separator and lighter mineral in the reject stream discharged from the top of the separator). It is required to have pure Mineral A in the product (that is, no Mineral B in the product). a) Calculate the terminal settling velocity of Mineral A in (static) water with particle size 10, 40 and 100 microns, respectively. (6 marks) b) Calculate the terminal settling velocity of Mineral B in (static) water with particle size 10, 40 and 100 microns, respectively. (6 marks) c) In the differential elutriation for particle separation, the direction of water flow is upward. Which of the following two particle size ranges (10-40 microns, or 40 - 100 microns) can give better particle separation? (2 marks) Justify your answer by finding the range of the upward velocity of water that enables the particle separation with desired product purity (100% Mineral A, no Mineral B) and maximum recovery of Mineral A (maximum mass fraction of Mineral A recovered to the product from the feed). (6 marks)

Step by Step Solution

There are 3 Steps involved in it

Step: 1

Get Instant Access to Expert-Tailored Solutions

See step-by-step solutions with expert insights and AI powered tools for academic success

Step: 2

Step: 3

Ace Your Homework with AI

Get the answers you need in no time with our AI-driven, step-by-step assistance

Get Started