Answered step by step

Verified Expert Solution

Question

1 Approved Answer

Quality Assurance Inspection Sampling: Consider the manufacturing process of commodity computer memory chips. In order to control outgoing quality we need to design a

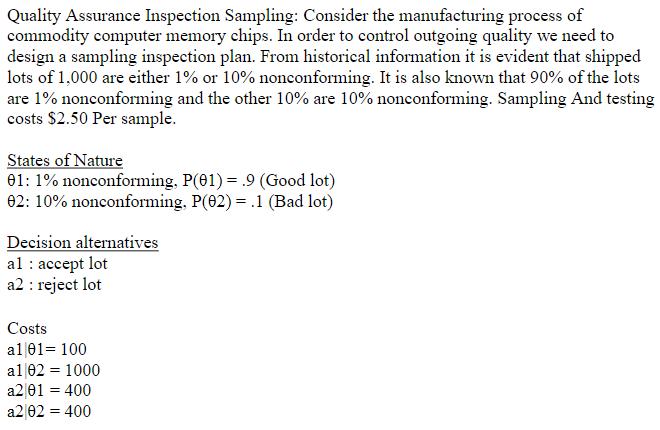

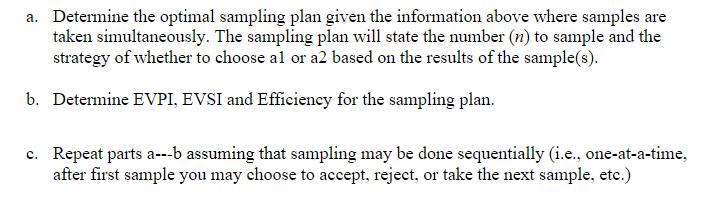

Quality Assurance Inspection Sampling: Consider the manufacturing process of commodity computer memory chips. In order to control outgoing quality we need to design a sampling inspection plan. From historical information it is evident that shipped lots of 1,000 are either 1% or 10% nonconforming. It is also known that 90% of the lots are 1% nonconforming and the other 10% are 10% nonconforming. Sampling And testing costs $2.50 Per sample. States of Nature 01: 1% nonconforming, P(01) = .9 (Good lot) 02: 10% nonconforming. P(02) = .1 (Bad lot) Decision alternatives al accept lot a2 : reject lot Costs al 01= 100 al 02 = 1000 a2|01 = 400 a2 02 = 400 a. Determine the optimal sampling plan given the information above where samples are taken simultaneously. The sampling plan will state the number (n) to sample and the strategy of whether to choose al or a2 based on the results of the sample(s). b. Determine EVPI, EVSI and Efficiency for the sampling plan. c. Repeat parts a---b assuming that sampling may be done sequentially (i.e., one-at-a-time, after first sample you may choose to accept, reject, or take the next sample, etc.)

Step by Step Solution

★★★★★

3.37 Rating (156 Votes )

There are 3 Steps involved in it

Step: 1

a The optimal sampling plan is to take 2 samples and to accept the l...

Get Instant Access to Expert-Tailored Solutions

See step-by-step solutions with expert insights and AI powered tools for academic success

Step: 2

Step: 3

Ace Your Homework with AI

Get the answers you need in no time with our AI-driven, step-by-step assistance

Get Started