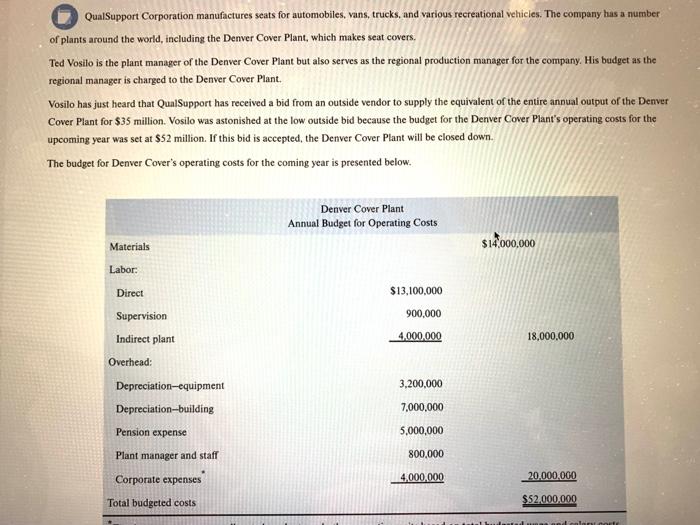

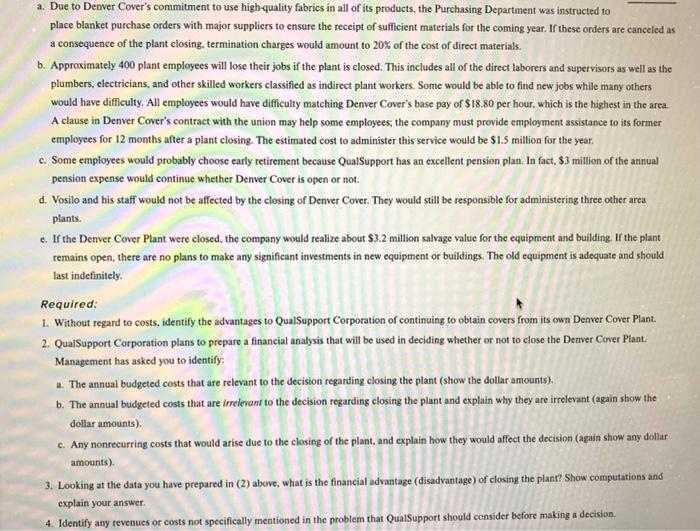

QualSupport Corporation manufactures seats for automobiles, vans, trucks, and various recreational vehicles. The company has a number of plants around the world, including the Denver Cover Plant, which makes seat covers. Ted Vosilo is the plant manager of the Denver Cover Plant but also serves as the regional production manager for the company. His budget as the regional manager is charged to the Denver Cover Plant. Vosilo has just heard that QualSupport has received a bid from an outside vendor to supply the equivalent of the entire annual output of the Denver Cower Plant for $35 million. Vosilo was astonished at the low outside bid because the budget for the Denver Cover Plant's operating costs for the upcoming year was set at $52 million. If this bid is accepted, the Denver Cover Plant will be closed down. The budget for Denver Cover's operating costs for the coming year is presented below. Denver Cover Plant Annual Budget for Operating Costs Materials $14.000,000 Labor: Direct $13,100,000 900,000 4,000,000 18,000,000 Supervision Indirect plant Overhead: Depreciation-equipment Depreciation-building 3,200,000 7,000,000 Pension expense 5,000,000 Plant manager and staff 800,000 4,000,000 20,000,000 Corporate expenses Total budgeted costs $52.000.000 dealanta a. Due to Denver Cover's commitment to use high-quality fabrics in all of its products, the Purchasing Department was instructed to place blanket purchase orders with major suppliers to ensure the receipt of sufficient materials for the coming year. If these orders are canceled as a consequence of the plant closing, termination charges would amount to 20% of the cost of direct materials. b. Approximately 400 plant employees will lose their jobs if the plant is closed. This includes all of the direct laborers and supervisors as well as the plumbers, electricians, and other skilled workers classified as indirect plant workers. Some would be able to find new jobs while many others would have difficulty. All employees would have difficulty matching Denver Cover's base pay of $18.80 per hour, which is the highest in the area. A clause in Denver Cover's contract with the union may help some employees; the company must provide employment assistance to its former employees for 12 months after a plant closing. The estimated cost to administer this service would be $1.5 million for the year. c. Some employees would probably choose early retirement because QualSupport has an excellent pension plan. In fact, $3 million of the annual pension expense would continue whether Denver Cover is open or not. d. Vosilo and his staff would not be affected by the closing of Denver Cover. They would still be responsible for administering three other arca plants. c. If the Denver Cover Plant were closed the company would realize about $3.2 million salvage value for the equipment and building. If the plant remains open, there are no plans to make any significant investments in new equipment or buildings. The old equipment is adequate and should last indefinitely a Required: 1. Without regard to costs, identify the advantages to QualSupport Corporation of continuing to obtain covers from its own Denver Cover Plant 2. QualSupport Corporation plans to prepare a financial analysis that will be used in deciding whether or not to close the Denver Cover Plant Management has asked you to identify a. The annual budgeted costs that are relevant to the decision regarding closing the plant (show the dollar amounts). b. The annual budgeted costs that are irrelevant to the decision regarding closing the plant and explain why they are irrelevant (again show the dollar amounts), c. Any nonrecurring costs that would arise due to the closing of the plant, and explain how they would affect the decision (again show any dollar amounts), 3. Looking at the data you have prepared in (2) above, what is the financial advantage (disadvantage) of closing the plant? Show computations and explain your answer 4. Identify any revenues or costs not specifically mentioned in the problem that QualSupport should consider before making a decision. 1) Relevant and irrelevant decision costs 5 Annual Budget for Operating costs Costs That Can Be Avoked (Saving Costs Not Avelded (No Saving Additional One time Costs Current Budget Materials 14,000,000 Labor Direct 13.100.000 0 Supervision 900,000 11 Indirect plant 4,000,000 12. Employment assistance 13 Total Labor 18.000 DOO 14 Overhead 15 Depreciation.eu 3,200.000 26 Depreciation building 7,000,000 27 Pension expense 5.000.000 18 Plantmanager and staff 300,000 19 Corporate expenses 4.000.000 Total Overhead 20,000,000 1 Total Costs 52.000000 22 2) Calculate the financial advantage or diadvantage of closing the plant 24 25 First Year 6 Cost of purchasing materials from vendor 27 Annual costs avoided by closing the plant # Non recurring fone-year costs of closing the plant Proceeds from sale of building and equipment 0 Financial advantage disadvantage) of closing the plant 31 32 Other consideration when deciding whether or not to close the plant Instructions Additional information is provided there Urge template provide and the addition information in the textbook, complete the following steps 1) Divide the annual budgeted costs for Denver Cover Plant into three categories relevant costs costs that can be avoided, irrelevant costs (costs that can't be avoided and additional nonrecurring conts that would be incurred the year the plant was shut down. Complete the template to the left (Columns 2. Looking at the data you calculated in above, calculate the Mandal advantage or disadvantage of closing the plant 3) Other than the financial information, what other factors would you consider when deciding whether or not to lose the plant? What are the advantages of leaving the plant open? Answer in the space below. 4) What is you conclusion? Should the plant be closed? Briefly explain in the space below Other Years 33 14 s a staui the latest in their Meiyalan 36 37