Answered step by step

Verified Expert Solution

Question

1 Approved Answer

Question 1 45 Marks A group of chemical and biochemical engineers is considering the design of a control system to control the biomass production from

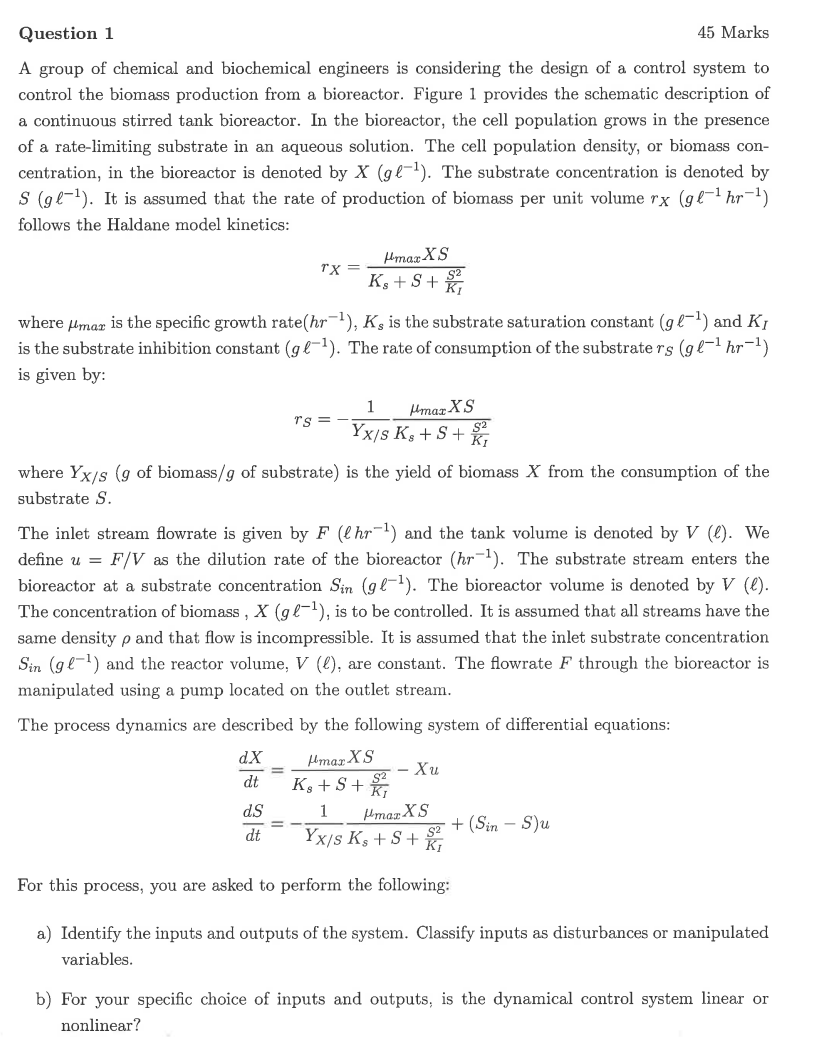

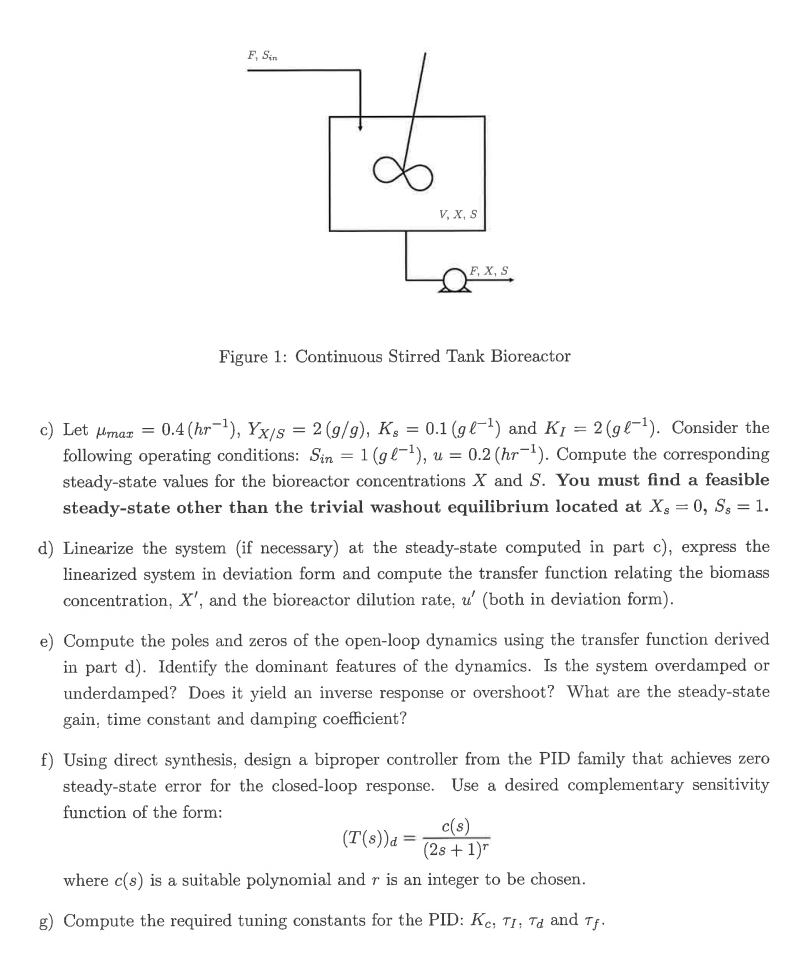

Question 1 45 Marks A group of chemical and biochemical engineers is considering the design of a control system to control the biomass production from a bioreactor. Figure 1 provides the schematic description of a continuous stirred tank bioreactor. In the bioreactor, the cell population grows in the presence of a rate-limiting substrate in an aqueous solution. The cell population density, or biomass concentration, in the bioreactor is denoted by X(g1). The substrate concentration is denoted by S(g1). It is assumed that the rate of production of biomass per unit volume rX(g1hr1) follows the Haldane model kinetics: rX=Ks+S+KIS2maxXS where max is the specific growth rate(hr1),Ks is the substrate saturation constant (g1) and KI is the substrate inhibition constant (g1). The rate of consumption of the substrate rS(g1hr1) is given by: rS=YX/S1Ks+S+KIS2maxXS where YX/S ( g of biomass /g of substrate) is the yield of biomass X from the consumption of the substrate S. The inlet stream flowrate is given by F(hr1) and the tank volume is denoted by V(). We define u=F/V as the dilution rate of the bioreactor (hr1). The substrate stream enters the bioreactor at a substrate concentration Sin(g1). The bioreactor volume is denoted by V(). The concentration of biomass, X(g1), is to be controlled. It is assumed that all streams have the same density and that flow is incompressible. It is assumed that the inlet substrate concentration Sin(g1) and the reactor volume, V(), are constant. The flowrate F through the bioreactor is manipulated using a pump located on the outlet stream. The process dynamics are described by the following system of differential equations: dtdXdtdS=Ks+S+KIS2maxXSXu=YX/S1Ks+S+KIS2maxXS+(SinS)u For this process, you are asked to perform the following: a) Identify the inputs and outputs of the system. Classify inputs as disturbances or manipulated variables. b) For your specific choice of inputs and outputs, is the dynamical control system linear or nonlinear? Figure 1: Continuous Stirred Tank Bioreactor c) Let max=0.4(hr1),YX/S=2(g/g),Ks=0.1(g1) and KI=2(g1). Consider the following operating conditions: Sin=1(g1),u=0.2(hr1). Compute the corresponding steady-state values for the bioreactor concentrations X and S. You must find a feasible steady-state other than the trivial washout equilibrium located at Xs=0,Ss=1. d) Linearize the system (if necessary) at the steady-state computed in part c), express the linearized system in deviation form and compute the transfer function relating the biomass concentration, X, and the bioreactor dilution rate, u (both in deviation form). e) Compute the poles and zeros of the open-loop dynamics using the transfer function derived in part d). Identify the dominant features of the dynamics. Is the system overdamped or underdamped? Does it yield an inverse response or overshoot? What are the steady-state gain, time constant and damping coefficient? f) Using direct synthesis, design a biproper controller from the PID family that achieves zero steady-state error for the closed-loop response. Use a desired complementary sensitivity function of the form: (T(s))d=(2s+1)rc(s) where c(s) is a suitable polynomial and r is an integer to be chosen. g) Compute the required tuning constants for the PID: Kc,I,d and f. Question 1 45 Marks A group of chemical and biochemical engineers is considering the design of a control system to control the biomass production from a bioreactor. Figure 1 provides the schematic description of a continuous stirred tank bioreactor. In the bioreactor, the cell population grows in the presence of a rate-limiting substrate in an aqueous solution. The cell population density, or biomass concentration, in the bioreactor is denoted by X(g1). The substrate concentration is denoted by S(g1). It is assumed that the rate of production of biomass per unit volume rX(g1hr1) follows the Haldane model kinetics: rX=Ks+S+KIS2maxXS where max is the specific growth rate(hr1),Ks is the substrate saturation constant (g1) and KI is the substrate inhibition constant (g1). The rate of consumption of the substrate rS(g1hr1) is given by: rS=YX/S1Ks+S+KIS2maxXS where YX/S ( g of biomass /g of substrate) is the yield of biomass X from the consumption of the substrate S. The inlet stream flowrate is given by F(hr1) and the tank volume is denoted by V(). We define u=F/V as the dilution rate of the bioreactor (hr1). The substrate stream enters the bioreactor at a substrate concentration Sin(g1). The bioreactor volume is denoted by V(). The concentration of biomass, X(g1), is to be controlled. It is assumed that all streams have the same density and that flow is incompressible. It is assumed that the inlet substrate concentration Sin(g1) and the reactor volume, V(), are constant. The flowrate F through the bioreactor is manipulated using a pump located on the outlet stream. The process dynamics are described by the following system of differential equations: dtdXdtdS=Ks+S+KIS2maxXSXu=YX/S1Ks+S+KIS2maxXS+(SinS)u For this process, you are asked to perform the following: a) Identify the inputs and outputs of the system. Classify inputs as disturbances or manipulated variables. b) For your specific choice of inputs and outputs, is the dynamical control system linear or nonlinear? Figure 1: Continuous Stirred Tank Bioreactor c) Let max=0.4(hr1),YX/S=2(g/g),Ks=0.1(g1) and KI=2(g1). Consider the following operating conditions: Sin=1(g1),u=0.2(hr1). Compute the corresponding steady-state values for the bioreactor concentrations X and S. You must find a feasible steady-state other than the trivial washout equilibrium located at Xs=0,Ss=1. d) Linearize the system (if necessary) at the steady-state computed in part c), express the linearized system in deviation form and compute the transfer function relating the biomass concentration, X, and the bioreactor dilution rate, u (both in deviation form). e) Compute the poles and zeros of the open-loop dynamics using the transfer function derived in part d). Identify the dominant features of the dynamics. Is the system overdamped or underdamped? Does it yield an inverse response or overshoot? What are the steady-state gain, time constant and damping coefficient? f) Using direct synthesis, design a biproper controller from the PID family that achieves zero steady-state error for the closed-loop response. Use a desired complementary sensitivity function of the form: (T(s))d=(2s+1)rc(s) where c(s) is a suitable polynomial and r is an integer to be chosen. g) Compute the required tuning constants for the PID: Kc,I,d and f

Question 1 45 Marks A group of chemical and biochemical engineers is considering the design of a control system to control the biomass production from a bioreactor. Figure 1 provides the schematic description of a continuous stirred tank bioreactor. In the bioreactor, the cell population grows in the presence of a rate-limiting substrate in an aqueous solution. The cell population density, or biomass concentration, in the bioreactor is denoted by X(g1). The substrate concentration is denoted by S(g1). It is assumed that the rate of production of biomass per unit volume rX(g1hr1) follows the Haldane model kinetics: rX=Ks+S+KIS2maxXS where max is the specific growth rate(hr1),Ks is the substrate saturation constant (g1) and KI is the substrate inhibition constant (g1). The rate of consumption of the substrate rS(g1hr1) is given by: rS=YX/S1Ks+S+KIS2maxXS where YX/S ( g of biomass /g of substrate) is the yield of biomass X from the consumption of the substrate S. The inlet stream flowrate is given by F(hr1) and the tank volume is denoted by V(). We define u=F/V as the dilution rate of the bioreactor (hr1). The substrate stream enters the bioreactor at a substrate concentration Sin(g1). The bioreactor volume is denoted by V(). The concentration of biomass, X(g1), is to be controlled. It is assumed that all streams have the same density and that flow is incompressible. It is assumed that the inlet substrate concentration Sin(g1) and the reactor volume, V(), are constant. The flowrate F through the bioreactor is manipulated using a pump located on the outlet stream. The process dynamics are described by the following system of differential equations: dtdXdtdS=Ks+S+KIS2maxXSXu=YX/S1Ks+S+KIS2maxXS+(SinS)u For this process, you are asked to perform the following: a) Identify the inputs and outputs of the system. Classify inputs as disturbances or manipulated variables. b) For your specific choice of inputs and outputs, is the dynamical control system linear or nonlinear? Figure 1: Continuous Stirred Tank Bioreactor c) Let max=0.4(hr1),YX/S=2(g/g),Ks=0.1(g1) and KI=2(g1). Consider the following operating conditions: Sin=1(g1),u=0.2(hr1). Compute the corresponding steady-state values for the bioreactor concentrations X and S. You must find a feasible steady-state other than the trivial washout equilibrium located at Xs=0,Ss=1. d) Linearize the system (if necessary) at the steady-state computed in part c), express the linearized system in deviation form and compute the transfer function relating the biomass concentration, X, and the bioreactor dilution rate, u (both in deviation form). e) Compute the poles and zeros of the open-loop dynamics using the transfer function derived in part d). Identify the dominant features of the dynamics. Is the system overdamped or underdamped? Does it yield an inverse response or overshoot? What are the steady-state gain, time constant and damping coefficient? f) Using direct synthesis, design a biproper controller from the PID family that achieves zero steady-state error for the closed-loop response. Use a desired complementary sensitivity function of the form: (T(s))d=(2s+1)rc(s) where c(s) is a suitable polynomial and r is an integer to be chosen. g) Compute the required tuning constants for the PID: Kc,I,d and f. Question 1 45 Marks A group of chemical and biochemical engineers is considering the design of a control system to control the biomass production from a bioreactor. Figure 1 provides the schematic description of a continuous stirred tank bioreactor. In the bioreactor, the cell population grows in the presence of a rate-limiting substrate in an aqueous solution. The cell population density, or biomass concentration, in the bioreactor is denoted by X(g1). The substrate concentration is denoted by S(g1). It is assumed that the rate of production of biomass per unit volume rX(g1hr1) follows the Haldane model kinetics: rX=Ks+S+KIS2maxXS where max is the specific growth rate(hr1),Ks is the substrate saturation constant (g1) and KI is the substrate inhibition constant (g1). The rate of consumption of the substrate rS(g1hr1) is given by: rS=YX/S1Ks+S+KIS2maxXS where YX/S ( g of biomass /g of substrate) is the yield of biomass X from the consumption of the substrate S. The inlet stream flowrate is given by F(hr1) and the tank volume is denoted by V(). We define u=F/V as the dilution rate of the bioreactor (hr1). The substrate stream enters the bioreactor at a substrate concentration Sin(g1). The bioreactor volume is denoted by V(). The concentration of biomass, X(g1), is to be controlled. It is assumed that all streams have the same density and that flow is incompressible. It is assumed that the inlet substrate concentration Sin(g1) and the reactor volume, V(), are constant. The flowrate F through the bioreactor is manipulated using a pump located on the outlet stream. The process dynamics are described by the following system of differential equations: dtdXdtdS=Ks+S+KIS2maxXSXu=YX/S1Ks+S+KIS2maxXS+(SinS)u For this process, you are asked to perform the following: a) Identify the inputs and outputs of the system. Classify inputs as disturbances or manipulated variables. b) For your specific choice of inputs and outputs, is the dynamical control system linear or nonlinear? Figure 1: Continuous Stirred Tank Bioreactor c) Let max=0.4(hr1),YX/S=2(g/g),Ks=0.1(g1) and KI=2(g1). Consider the following operating conditions: Sin=1(g1),u=0.2(hr1). Compute the corresponding steady-state values for the bioreactor concentrations X and S. You must find a feasible steady-state other than the trivial washout equilibrium located at Xs=0,Ss=1. d) Linearize the system (if necessary) at the steady-state computed in part c), express the linearized system in deviation form and compute the transfer function relating the biomass concentration, X, and the bioreactor dilution rate, u (both in deviation form). e) Compute the poles and zeros of the open-loop dynamics using the transfer function derived in part d). Identify the dominant features of the dynamics. Is the system overdamped or underdamped? Does it yield an inverse response or overshoot? What are the steady-state gain, time constant and damping coefficient? f) Using direct synthesis, design a biproper controller from the PID family that achieves zero steady-state error for the closed-loop response. Use a desired complementary sensitivity function of the form: (T(s))d=(2s+1)rc(s) where c(s) is a suitable polynomial and r is an integer to be chosen. g) Compute the required tuning constants for the PID: Kc,I,d and f Step by Step Solution

There are 3 Steps involved in it

Step: 1

Get Instant Access to Expert-Tailored Solutions

See step-by-step solutions with expert insights and AI powered tools for academic success

Step: 2

Step: 3

Ace Your Homework with AI

Get the answers you need in no time with our AI-driven, step-by-step assistance

Get Started