Answered step by step

Verified Expert Solution

Question

1 Approved Answer

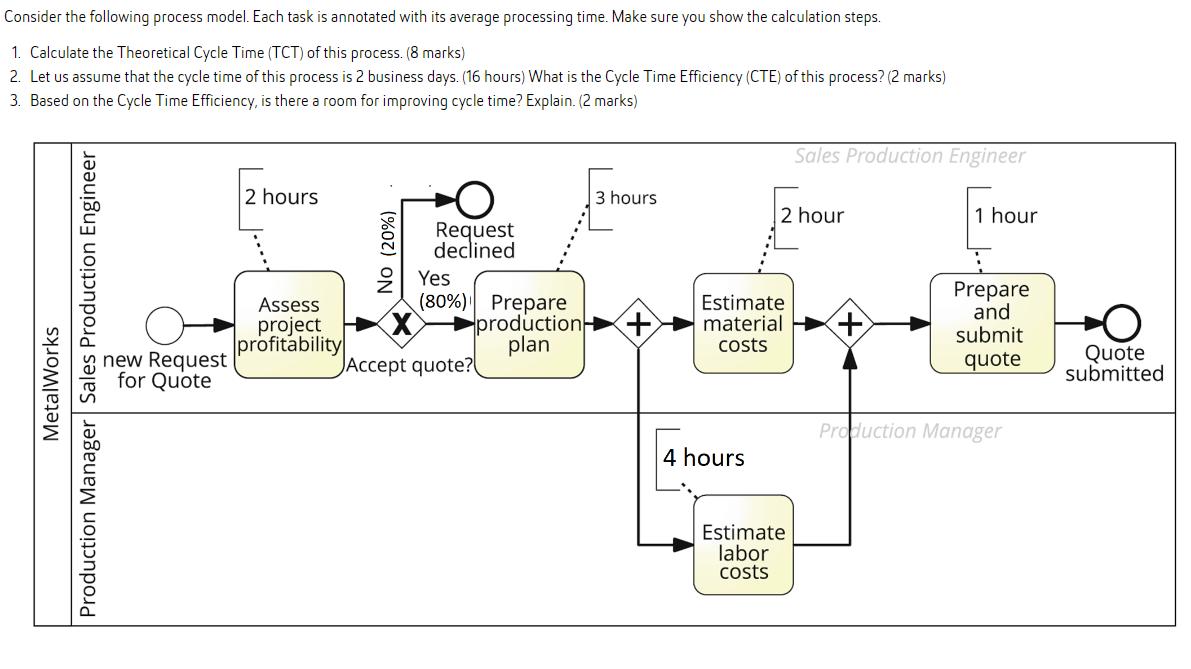

Consider the following process model. Each task is annotated with its average processing time. Make sure you show the calculation steps. 1. Calculate the

Consider the following process model. Each task is annotated with its average processing time. Make sure you show the calculation steps. 1. Calculate the Theoretical Cycle Time (TCT) of this process. (8 marks) 2. Let us assume that the cycle time of this process is 2 business days. (16 hours) What is the Cycle Time Efficiency (CTE) of this process? (2 marks) 3. Based on the Cycle Time Efficiency, is there a room for improving cycle time? Explain. (2 marks) MetalWorks Production Manager Sales Production Engineer new Request for Quote 2 hours Assess project profitability No (20%) Request declined Yes (80%) Prepare production plan JAccept quote? 3 hours Estimate material costs 4 hours 2 hour Sales Production Engineer Estimate labor costs 1 hour Prepare and submit quote Production Manager Quote submitted

Step by Step Solution

There are 3 Steps involved in it

Step: 1

The image describes a process model that includes a sequence of tasks with annotated processing times Lets go through the process step by step to calculate the Theoretical Cycle Time TCT and determine the Cycle Time Efficiency CTE based on the provided information 1 To calculate the Theoretical Cycle Time TCT we will add up the times for each task along the longest path through the process since not all tasks may necessarily be executed in each iteration of the process Starting from assess new Request for Quote and assuming the request is accepted which happens 80 of the time Assess project profitability 2 hours Prepare production plan 3 hours Estimate material costs 2 hours since it is in parallel with Estimate labor costs we only take the longest path which is via Estimate labor costs Estimate labor costs 4 hours longest path Prepare and submit quote 1 hour Adding these times gives us the total for the longest path 2 3 4 1 10 hours So the Theoretical Cycle Time TCT is 10 hours 2 To calculate the Cycle Time Efficiency CTE we use the formula CTE Valueadded Time Total Cycle Time x 100 In this case the valueadded time is the TCT we have calculated 10 hours and the total cycle time is given as 16 hours 2 business days Thus CTE 10 hours 16 hours x 100 625 3 Based on the Cycle Time Efficiency there indeed appears to be room for improving cycle time An efficiency of 625 indicates that there is 375 of the cycle time that is not directly adding value to the process Improvements could be sought by Reducing nonvalueadded activities or wait times between tasks Streamlining operations to minimize the time required for each task Rearranging tasks to occur in parallel where possible Automating certain parts of the process to reduce manual processing time ...

Get Instant Access to Expert-Tailored Solutions

See step-by-step solutions with expert insights and AI powered tools for academic success

Step: 2

Step: 3

Ace Your Homework with AI

Get the answers you need in no time with our AI-driven, step-by-step assistance

Get Started