Question

Lavare, located in the Chicago suburbs, is a major manufacturer of stainless steel sinks. Lavare is in the middle of the demand and supply planning

Lavare, located in the Chicago suburbs, is a major manufacturer of stainless steel sinks. Lavare is in the middle of the demand and supply planning exercise for the coming year. Anticipated monthly demand from distributors over the 12 months in shown in the table below.

Capacity at Lavare is governed by the number of machine operators it hires. The firm works 20 days a month, with a regular operating shift of eight hours per day. Any time beyond that is considered overtime. Regular-time pay is $15 per hour and overtime is $22 per hour. Overtime is limited to 20 hours per month per employee. The plant currently has 250 employees. Each sink requires two hours of labor input. It costs $3 to carry a sink in inventory for a month. Materials cost per sink is $40. Sinks are sold to distributors at a price of $125 each. We assume that no stockouts are allowed and the starting inventory entering January is 5,000 units and the desired ending inventory in December is also 5,000 units.

Market research has indicated that a promotion dropping prices by 1 percent in a given month will increase sales in that month by 20 percent and bring forward 10 percent demand from each of the following two months. Thus, a 1 percent drop in price in March increase sales in March by 3,000(=0.2 * 15,000) and shifts 1,800(=0.1 * 18,000) units in demand from April and 2,500(=0.1 * 25,000) units from May forward to March.

Table – Anticipated Monthly Demand at Lavare

Month | Demand Forecast |

January | 10,000 |

February | 11,000 |

March | 16,000 |

April | 19,000 |

May | 22,000 |

June | 25,000 |

July | 31,000 |

August | 28,000 |

September | 22,000 |

October | 19,000 |

November | 13,000 |

December | 12,000 |

Please create an excel file and use only the attached screenshots format in the excel file. Show the solutions and the formulas in the excel file.

What is the optimal production plan for the year if we assume no promotions? What is the annual profit from this plan? What is the cost of this plan?

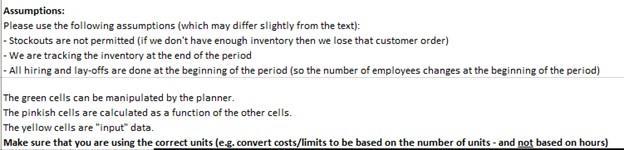

Assumptions: Please use the following assumptions (which may differ slightly from the text): -Stockouts are not permitted (if we don't have enough inventory then we lose that customer order) -We are tracking the inventory at the end of the period -All hiring and lay-offs are done at the beginning of the period (so the number of employees changes at the beginning of the period) The green cells can be manipulated by the planner. The pinkish cells are calculated as a function of the other cells. The yellow cells are "input" data. Make sure that you are using the correct units (e.g. convert costs/limits to be based on the number of units - and not based on hours)

Step by Step Solution

There are 3 Steps involved in it

Step: 1

Sure lets address the rejection points and provide a stepbystep answer along with the required diagram and realtime example Heres a structured approach to the problem Problem Details Recap Lavare manu...

Get Instant Access to Expert-Tailored Solutions

See step-by-step solutions with expert insights and AI powered tools for academic success

Step: 2

Step: 3

Ace Your Homework with AI

Get the answers you need in no time with our AI-driven, step-by-step assistance

Get Started