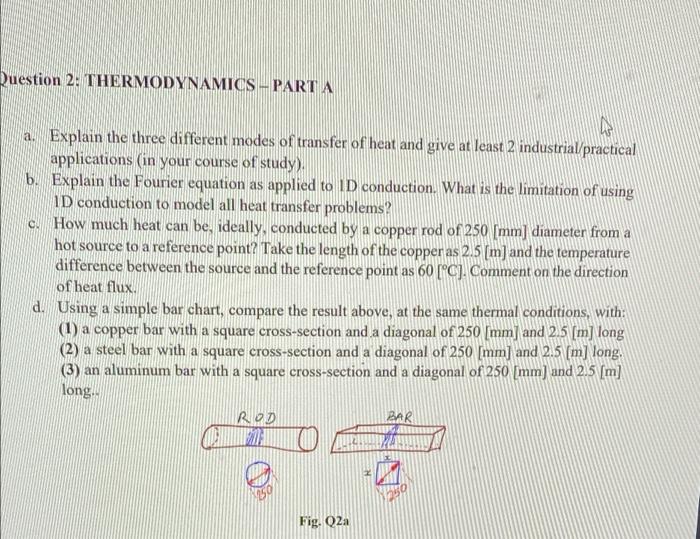

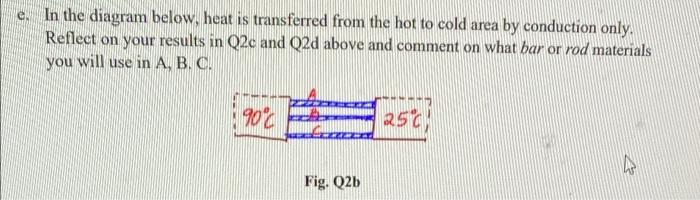

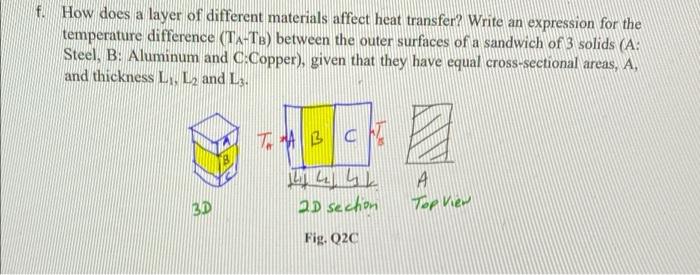

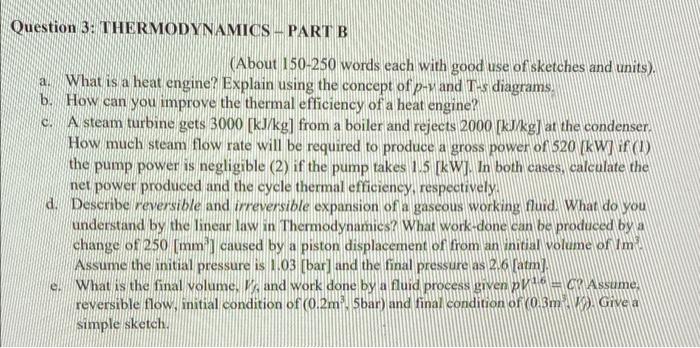

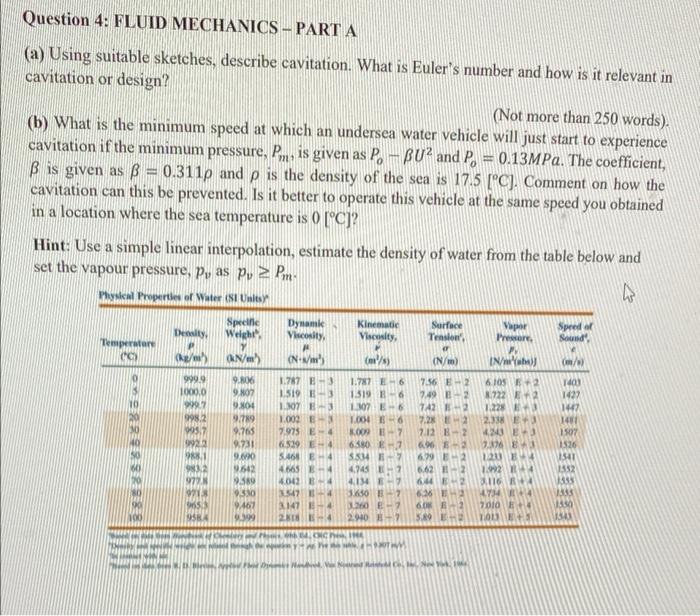

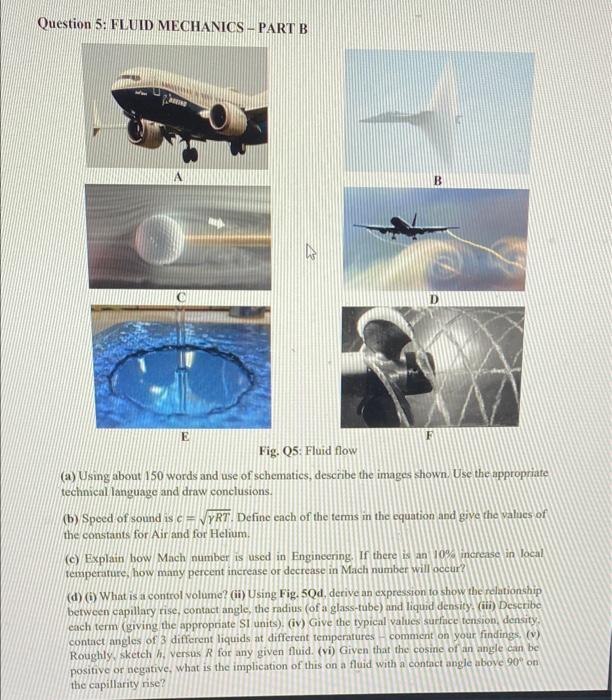

Question 1: MATERIAL SCIENCE a. Describe the main features of the stress-strain diagram. b. Discuss the regions on a generic stress-strain curve where the Hooke's law applies. Explain how a material (i) can reach the elastic and plastic regions of the stress-strain curve (11) behaves outside the elastic region. All terms must be clear in your description. c. Using a single (well scaled or exaggerated scale) stress-strain curve, compare the following metals: High speed steel, Mild steel, Cast-iron, Oak-wood, Copper and pre-cast concrete. d. Comment on the implications of the size of the total area under a stress-strain curve, e.g. what does this say about a material. e. Using suitable sketches and descriptions, discuss the phase transformations for (1) high strength steel and (2) mild steel. Describe the following and the kind of materials they apply to Eutectie point, Peritectie reaction points, austenitic temperature, g. How can a sequence of normalising, quenching, carburizing or casehardening affecta material? Describe how any of these can be used to improve workability of sheet metals materials used in food processing. h. Why is alloying done? Using a Pb-Sn or Cu-Zn phase diagram, explain how you can achieve a 30% wt of the alloying materials. Comment on the phase composition at room temperature (In each of the questions above, aim for about 100-250 words as much as you can) Question 2: THERMODYNAMICS - PART A D a. Explain the three different modes of transfer of heat and give at least 2 industrial practical applications (in your course of study). b. Explain the Fourier equation as applied to ID conduction. What is the limitation of using ID conduction to model all heat transfer problems? C. How much heat can be, ideally, conducted by a copper rod of 250 (mm) diameter from a hot source to a reference point? Take the length of the copper as 2.5 [m] and the temperature difference between the source and the reference point as 60 [C]. Comment on the direction of heat flux. d. Using a simple bar chart, compare the result above, at the same thermal conditions, with: (1) a copper bar with a square cross-section and a diagonal of 250 (mm) and 2.5 [m] long (2) a steel bar with a square cross-section and a diagonal of 250 (mm) and 2.5 (m) long, (3) an aluminum bar with a square cross-section and a diagonal of 250 (mm) and 2.5 [m] long. ROD BAR - Fig. Q2a In the diagram below, heat is transferred from the hot to cold area by conduction only. Reflect on your results in Q2c and Q2d above and comment on what bar or rod materials you will use in A, B.C. 90C 25% no Fig. Q2b f. How does a layer of different materials affect heat transfer? Write an expression for the temperature difference (TA-TB) between the outer surfaces of a sandwich of 3 solids (A: Steel, B: Aluminum and C Copper), given that they have equal cross-sectional areas, A. and thickness LL2 and Ly. 73 7. A 3 CZ VUI L. CL 2D section A Top View 3D Fig. 220 a. Question 3: THERMODYNAMICS - PART B (About 150-250 words each with good use of sketches and units) What is a heat engine? Explain using the concept of p-vand T-s diagrams. b. How can you improve the thermal efficiency of a heat engine? c. A steam turbine gets 3000 [kJ/kg] from a boiler and rejects 2000 Iki/kg] at the condenser How much steam flow rate will be required to produce a gross power of 520 /kW if (1) the pump power is negligible (2) if the pump takes 1 5 [kW]. In both cases, calculate the net power produced and the cycle thermal efficiency respectively d. Describe reversible and irreversible expansion of a gaseous working Muid. What do you understand by the linear law in Thermodynamics? What work done can be produced by a change of 250 [mm] caused by a piston displacement of from an initial volume of Im Assume the initial pressure is 1.03 [bar) and the final pressure as 2.6 [atm What is the final volume. 1 and work done by a fluid process given = o Assume, reversible flow, initial condition of (0.2m Sbar) and final condition of (0.3m. Give a simple sketch. Question 4: FLUID MECHANICS - PART A (a) Using suitable sketches, describe cavitation. What is Euler's number and how is it relevant in cavitation or design? (Not more than 250 words). (b) What is the minimum speed at which an undersea water vehicle will just start to experience cavitation if the minimum pressure, Pm, is given as P. - BU2 and P = 0.13MPa. The coefficient, B is given as B = 0.311p and p is the density of the sea is 17.5 [C]. Comment on how the cavitation can this be prevented. Is it better to operate this vehicle at the same speed you obtained in a location where the sea temperature is 0 [C]? Hint: Use a simple linear interpolation, estimate the density of water from the table below and set the vapour pressure, P, as p, 2 P ws Physical Properties of Water ( Units 3 Density, Specific Weight Dynamk Viscosity, Kinetic Viscosity, Surface Tenslowly Speed of Sound Temperatur (C) Nm) (N.' (m/s) (N/m) IN (m/w) 1.787 E-6 999.9 0.0 99.7 982 6105 8.722 E 1.228 2.38 E 14 1507 9920 9. 9 NOW 9 NOE 9.789 9.763 731 NO 1642 389 310 2461 9.399 1.787 - 1.519 1.107 E 1.002 E- 7.975 E 6-529 E-4 5446 E 4665 -4 404 4 542 - 4 141 1 284 107 1.00 16 RO 6.380 5514 4.945 413E 7.56 E2 7.490 7A2 B 7.22 7.12 12 6.62 6.79 E-2 6.62 1-2 64 636 602 5.89 1352 60 E- 2.910 - OSRA 10 MOCHT MOTH NY Question 5: FLUID MECHANICS - PART B B IN D E Fig. Q5: Fluid flow (a) Using about 150 words and use of schematics, describe the images shown. Use the appropriate technical language and draw conclusions. (b) Speed of sound is c = VYRT. Define each of the terms in the equation and give the values of the constants for Air and for Helium (c) Explain bow Mach number is used in Engineering. If there is an 10% increase in local temperature, how many percent increase or decrease in Mach number will occur? (d) () What is a control volume? (ii) Using Fig. 50d, derive an expression to show the relationship between capillary rise, contact angle, the radius (of a glass-tube) and liquid density (ii) Describe each term (giving the appropriate SI units). (iv) Give the typical values surface tension, density contact angles of 3 different liquids at different temperatures comment on your findings. (v) Roughly sketch h, Versus R for any given fluid. (vi) Given that the cosire of an angle can be positive or negative, what is the implication of this on a fluid with a contact angle above 90' on the capillarity rise