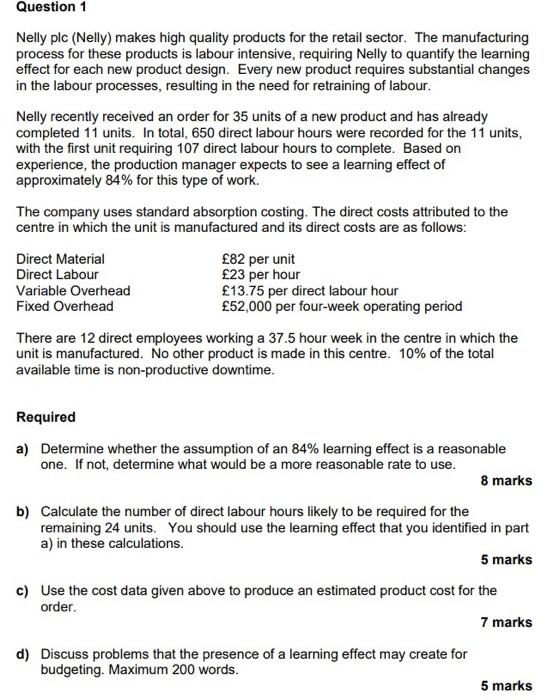

Question 1 Nelly plc (Nelly) makes high quality products for the retail sector. The manufacturing process for these products is labour intensive, requiring Nelly to quantify the learning effect for each new product design. Every new product requires substantial changes in the labour processes, resulting in the need for retraining of labour. Nelly recently received an order for 35 units of a new product and has already completed 11 units. In total, 650 direct labour hours were recorded for the 11 units, with the first unit requiring 107 direct labour hours to complete. Based on experience, the production manager expects to see a learning effect of approximately 84% for this type of work. The company uses standard absorption costing. The direct costs attributed to the centre in which the unit is manufactured and its direct costs are as follows: Direct Material 82 per unit Direct Labour 23 per hour Variable Overhead 13.75 per direct labour hour Fixed Overhead 52,000 per four-week operating period There are 12 direct employees working a 37.5 hour week in the centre in which the unit is manufactured. No other product is made in this centre. 10% of the total available time is non-productive downtime. Required a) Determine whether the assumption of an 84% learning effect is a reasonable one. If not, determine what would be a more reasonable rate to use. 8 marks b) Calculate the number of direct labour hours likely to be required for the remaining 24 units. You should use the learning effect that you identified in part a) in these calculations. 5 marks c) Use the cost data given above to produce an estimated product cost for the order. 7 marks d) Discuss problems that the presence of a learning effect may create for budgeting. Maximum 200 words. 5 marks Question 1 Nelly plc (Nelly) makes high quality products for the retail sector. The manufacturing process for these products is labour intensive, requiring Nelly to quantify the learning effect for each new product design. Every new product requires substantial changes in the labour processes, resulting in the need for retraining of labour. Nelly recently received an order for 35 units of a new product and has already completed 11 units. In total, 650 direct labour hours were recorded for the 11 units, with the first unit requiring 107 direct labour hours to complete. Based on experience, the production manager expects to see a learning effect of approximately 84% for this type of work. The company uses standard absorption costing. The direct costs attributed to the centre in which the unit is manufactured and its direct costs are as follows: Direct Material 82 per unit Direct Labour 23 per hour Variable Overhead 13.75 per direct labour hour Fixed Overhead 52,000 per four-week operating period There are 12 direct employees working a 37.5 hour week in the centre in which the unit is manufactured. No other product is made in this centre. 10% of the total available time is non-productive downtime. Required a) Determine whether the assumption of an 84% learning effect is a reasonable one. If not, determine what would be a more reasonable rate to use. 8 marks b) Calculate the number of direct labour hours likely to be required for the remaining 24 units. You should use the learning effect that you identified in part a) in these calculations. 5 marks c) Use the cost data given above to produce an estimated product cost for the order. 7 marks d) Discuss problems that the presence of a learning effect may create for budgeting. Maximum 200 words. 5 marks