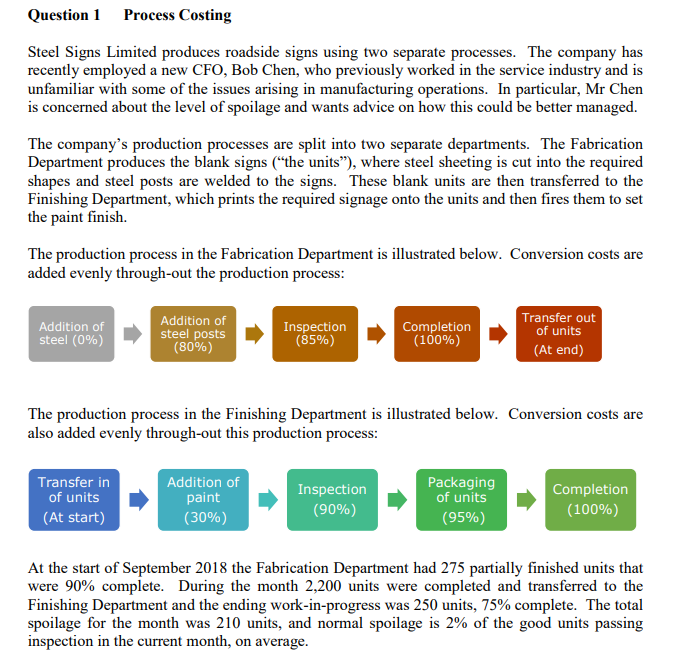

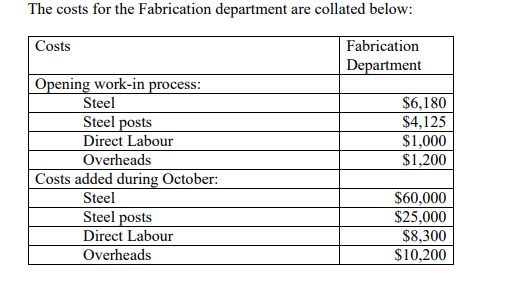

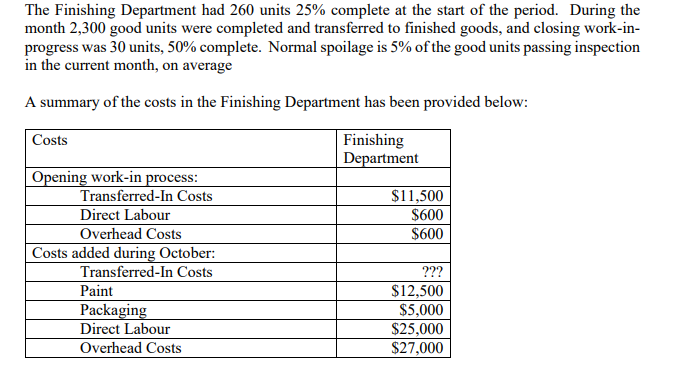

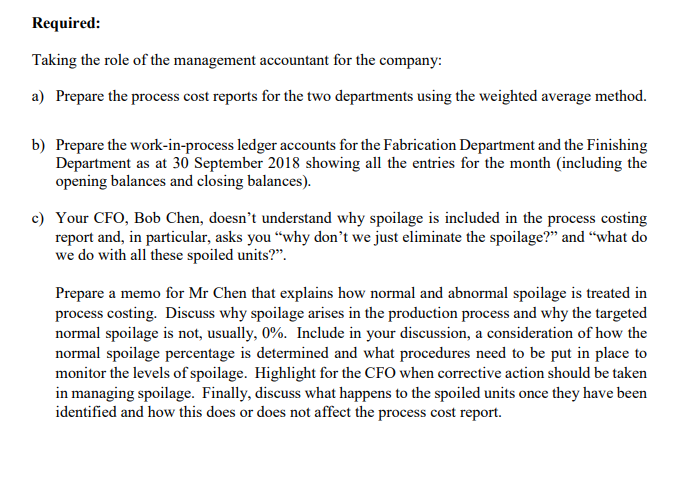

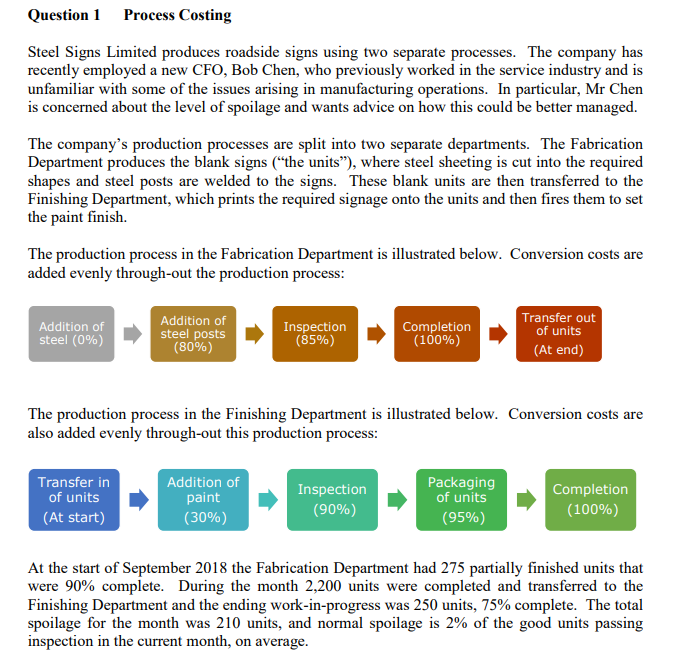

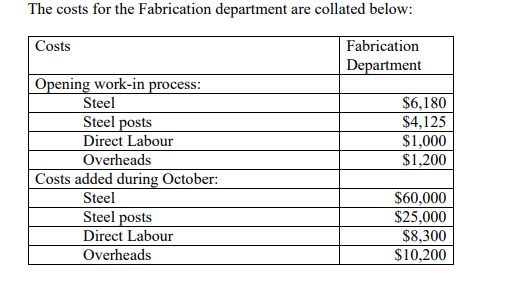

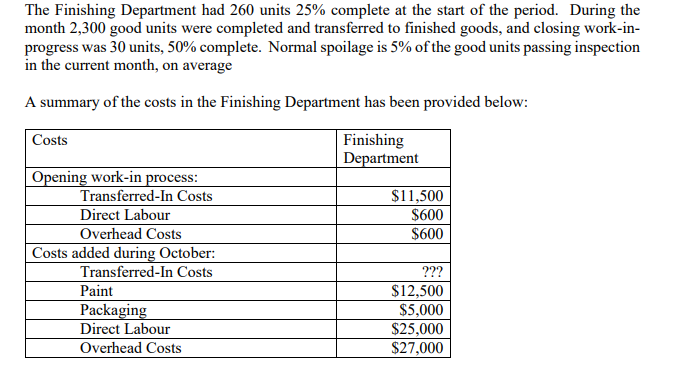

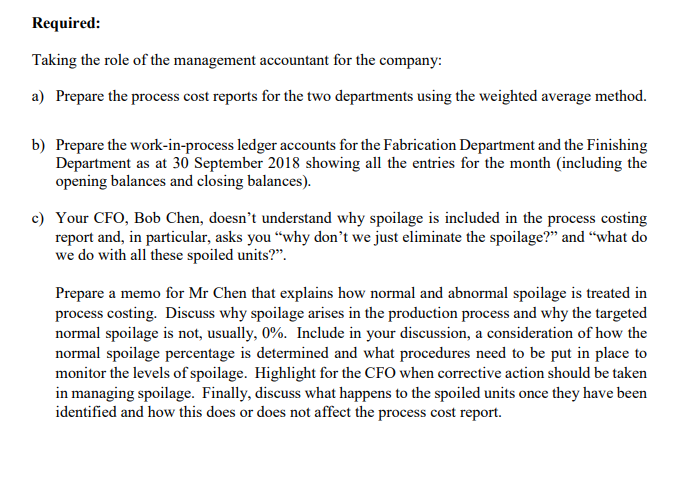

Question 1 Process Costing Steel Signs Limited produces roadside signs using two separate processes. The company has recently employed a new CFO, Bob Chen, who previously worked in the service industry and is unfamiliar with some of the issues arising in manufacturing operations. In particular, Mr Chen is concerned about the level of spoilage and wants advice on how this could be better managed. The company's production processes are split into two separate departments. The Fabrication Department produces the blank signs ("the units"), where steel sheeting is cut into the required shapes and steel posts are welded to the signs. These blank units are then transferred to the Finishing Department, which prints the required signage onto the units and then fires them to set the paint finish. The production process in the Fabrication Department is illustrated below. Conversion costs are added evenly through-out the production process Addition of steel (096) Addition of steel posts (80%) Inspectiorn (85%) Completion (100%) Transfer out of units (At end) The production process in the Finishing Department is illustrated below. Conversion costs are also added evenly through-out this production process Transfer in of units Addition of paint (30%) Inspection (90%) Packaging of units Completion (100%) (At start) (95%) At the start of September 2018 the Fabrication Department had 275 partially finished units that were 90% complete. During the month 2,200 units were completed and transferred to the Finishing Department and the ending work-in-progress was 250 units, 75% complete. The total spoilage for the month was 210 units, and normal spoilage is 2% of the good units passing inspection in the current month, on average Question 1 Process Costing Steel Signs Limited produces roadside signs using two separate processes. The company has recently employed a new CFO, Bob Chen, who previously worked in the service industry and is unfamiliar with some of the issues arising in manufacturing operations. In particular, Mr Chen is concerned about the level of spoilage and wants advice on how this could be better managed. The company's production processes are split into two separate departments. The Fabrication Department produces the blank signs ("the units"), where steel sheeting is cut into the required shapes and steel posts are welded to the signs. These blank units are then transferred to the Finishing Department, which prints the required signage onto the units and then fires them to set the paint finish. The production process in the Fabrication Department is illustrated below. Conversion costs are added evenly through-out the production process Addition of steel (096) Addition of steel posts (80%) Inspectiorn (85%) Completion (100%) Transfer out of units (At end) The production process in the Finishing Department is illustrated below. Conversion costs are also added evenly through-out this production process Transfer in of units Addition of paint (30%) Inspection (90%) Packaging of units Completion (100%) (At start) (95%) At the start of September 2018 the Fabrication Department had 275 partially finished units that were 90% complete. During the month 2,200 units were completed and transferred to the Finishing Department and the ending work-in-progress was 250 units, 75% complete. The total spoilage for the month was 210 units, and normal spoilage is 2% of the good units passing inspection in the current month, on average