Answered step by step

Verified Expert Solution

Question

1 Approved Answer

Question 1 You are tasked with performing both an order of magnitude ( Class 5 ) and study estimate ( Class 4 ) for the

Question

You are tasked with performing both an order of magnitude Class and study estimate Class for the capital cost of a Maleic Anhydride production plant. A process flow diagram PFD and major plant item summary is appended to this brief.

The plant nominally produces tonnes per year of Maleic Anhydride, at a purity of ww using ethylbenzene as the feedstock. Byproducts generated include hydrogen, benzene and toluene. The plant is located on the US Gulf Coast and was constructed in the year

As part of your estimates, you are required to:

Use a plant correlation to estimate the cost of a tpa Maleic Anhydride production plant and convert the cost to US$ in Class estimate

Use the reference cost correlations provided to estimate the purchase cost of each item of major equipment and convert the item cost to US$ in You are not required to account for installation factors, however, must consider the relevant material of construction for each item Class estimate

You may use other correlations provided they are clearly presented and cited.

Using an appropriate Lang Factor, convert the total estimated equipment cost to an estimated plant cost in US$ year Class estimate

Costs of each item should be clearly summarised in a table, together with the total equipment cost. Material used in calculations must be clearly cited.

Sample calculations for the cost estimate of each item should be clearly presented in an appendix to the submission.

Any assumptions made should be clearly presented together with citations to any relevant material.

Process Description from Turton et al

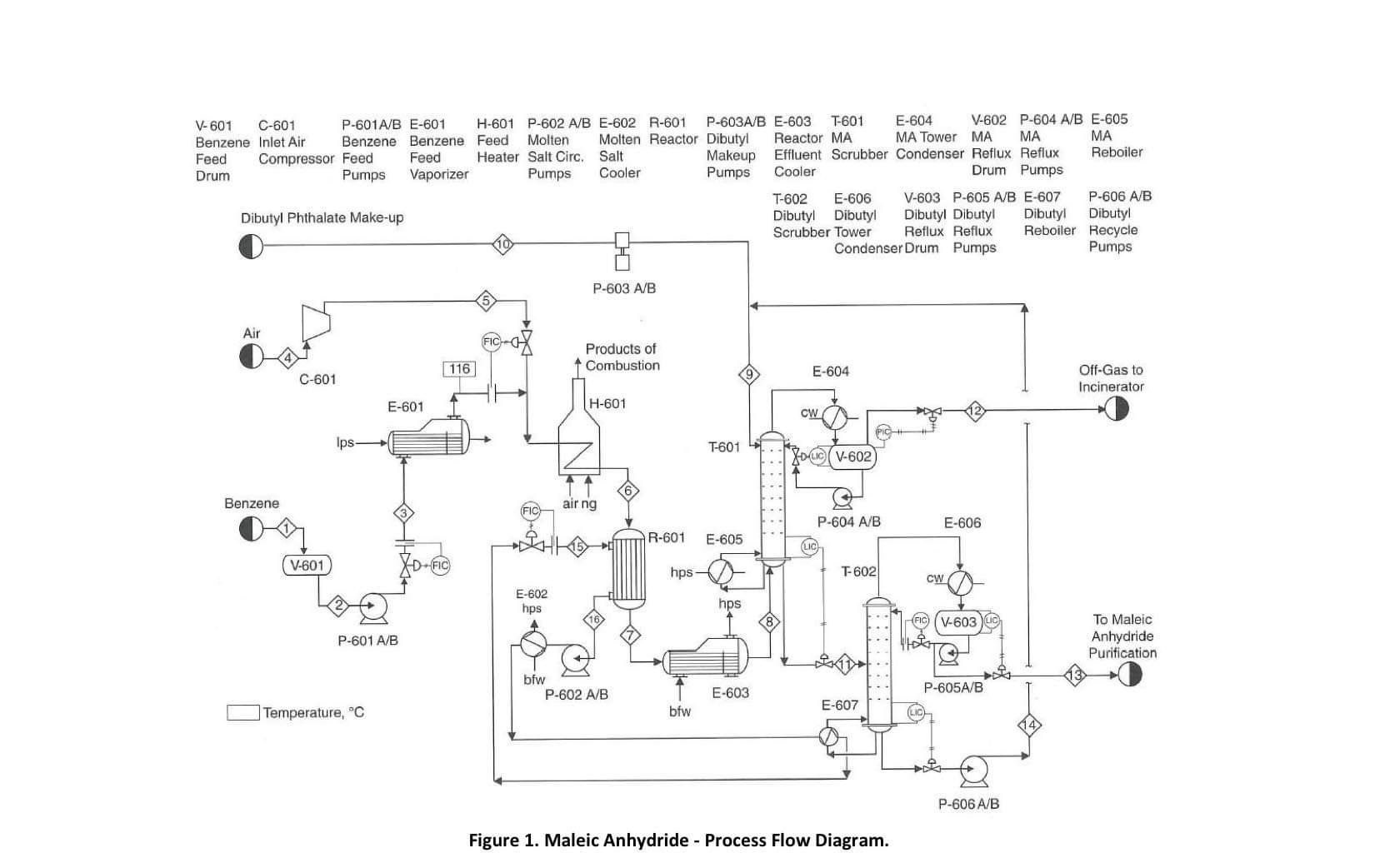

Currently, the preferred route to maleic anhydride manufacture in the US is via isobutene conversion in fluidized bed reactors. However, an alternate route via benzene may be carried out using a shellandtube reactor, with catalyst in the tubes and a cooling medium circulated through the shell. This configuration is shown in Figure below.

Benzene feed is vaporized in exchanger E mixed with compressed air, and then heated in a fired heated, prior to being sent to a packedbed catalyticreactor, where the following reactions take place:

All reactions are highly exothermic. For this reason, the ratio of air to benzene entering the reactor is kept very high. A typical reactor inlet Stream concentration of approximately vol of benzene in air is used. Cooling is achieved by circulating molten salt concurrently through the shell of the reactor and across the tubes containing the catalyst and reactant gases. The molten salt is cooled in two external heat exchangers, E and E prior to returning to the reactor.

The reactor effluent Stream containing small amounts of unreacted benzene, maleic anhydride, quinone, and combustion products is cooled in exchanger and then sent to an absorber column, T In the absorber T vapour feed is contacted countercurrently with a recycled heavy organic solvent dibutyl phthalate via Stream The solvent absorbs the maleic anhydride, quinone, and small amounts of water. Any water in the solvent leaving the base of the absorber T reacts with maleic anhydride to form maleic acid, which must be removed and purified from the maleic anhydride.

The bottoms product from the absorber is sent to a separation tower T where the dibutyl phthalate solvent is recovered as the bottom product Stream and recycled back to the absorber A small amount of fresh solvent Stream is combined with the recovered solvent to account for minor losses. The overhead product Stream from the separation tower T is sent for further purification via distillation where maleic anhydride is recovered at a purity of mol For simplicity, this final purification step has not been included in the process flow diagram of Figure or included in the stream table below ie Table

Table Major Equipment Summary for the Maleic Anhydride Production Process shown in Figure below

tabletableCompressor and DrivesCCentrifugalelectric driveCarbon steelDischarge pressure kPa

Step by Step Solution

There are 3 Steps involved in it

Step: 1

Get Instant Access to Expert-Tailored Solutions

See step-by-step solutions with expert insights and AI powered tools for academic success

Step: 2

Step: 3

Ace Your Homework with AI

Get the answers you need in no time with our AI-driven, step-by-step assistance

Get Started