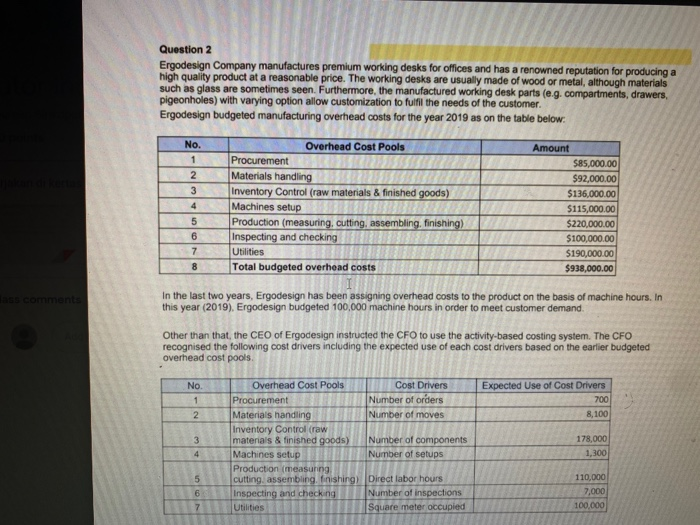

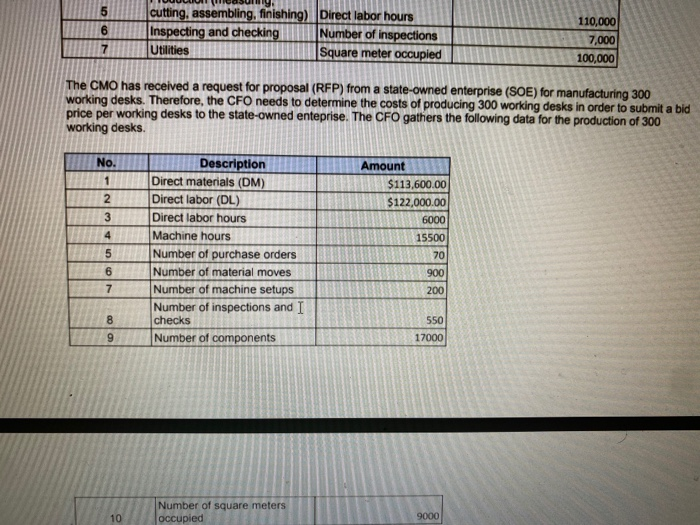

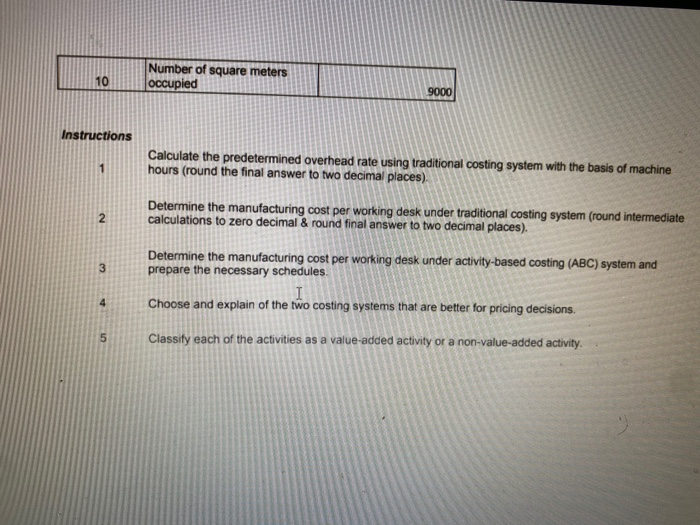

Question 2 Ergodesign Company manufactures premium working desks for offices and has a renowned reputation for producing a high quality product at a reasonable price. The working desks are usually made of wood or metal, although materials such as glass are sometimes seen. Furthermore, the manufactured working desk parts (e.g. compartments, drawers, pigeonholes) with varying option allow customization to fulfil the needs of the customer. Ergodesign budgeted manufacturing overhead costs for the year 2019 as on the table below: No. Overhead Cost Pools Amount 1 Procurement 585,000.00 2 Materials handling $92,000.00 3 Inventory Control (raw materials & finished goods) $136,000.00 Machines setup $115,000.00 5 Production (measuring, cutting, assembling, finishing) $220,000.00 6 Inspecting and checking $100,000.00 7 Utilities $190,000.00 8 Total budgeted overhead costs $938,000.00 4 Comments In the last two years, Ergodesign has been assigning overhead costs to the product on the basis of machine hours. In this year (2019), Ergodesign budgeted 100,000 machine hours in order to meet customer demand Other than that, the CEO of Ergodesign instructed the CFO to use the activity-based costing system. The CFO recognised the following cost drivers including the expected use of each cost drivers based on the earlier budgeted overhead cost pools No 1 2. Expected Use of Cost Drivers 700 8,100 3 Overhead Cost Pools Cost Drivers Procurement Number of orders Materials handling Number of moves Inventory Control (raw materials & finished goods) Number of components Machines setup Number of setups Production (measuring cutting, assembling, finishing Direct labor hours Inspecting and check ng Number of inspections Utilities Square meter occupied 178,000 1,300 5 6 110,000 7,000 100.000 7 5 6 cutting, assembling, finishing) Direct labor hours Inspecting and checking Number of inspections Utilities Square meter occupied 110,000 7,000 100,000 7 The CMO has received a request for proposal (RFP) from a state-owned enterprise (SOE) for manufacturing 300 working desks. Therefore, the CFO needs to determine the costs of producing 300 working desks in order to submit a bid price per working desks to the state-owned enteprise. The CFO gathers the following data for the production of 300 working desks. No. 1 2 3 4 Description Direct materials (DM) Direct labor (DL) Direct labor hours Machine hours Number of purchase orders Number of material moves Number of machine setups Number of inspections and I checks Number of components Amount $113,600.00 $122,000.00 6000 15500 70 900 5 6 7 200 8 550 17000 9 Number of square meters Occupied 10 9000 10 Number of square meters occupied 9000 Instructions Calculate the predetermined overhead rate using traditional costing system with the basis of machine hours (round the final answer to two decimal places) 2 3 Determine the manufacturing cost per working desk under traditional costing system (round intermediate calculations to zero decimal & round final answer to two decimal places). Determine the manufacturing cost per working desk under activity-based costing (ABC) system and prepare the necessary schedules I Choose and explain of the two costing systems that are better for pricing decisions. Classify each of the activities as a value-added activity or a non-value-added activity. 5