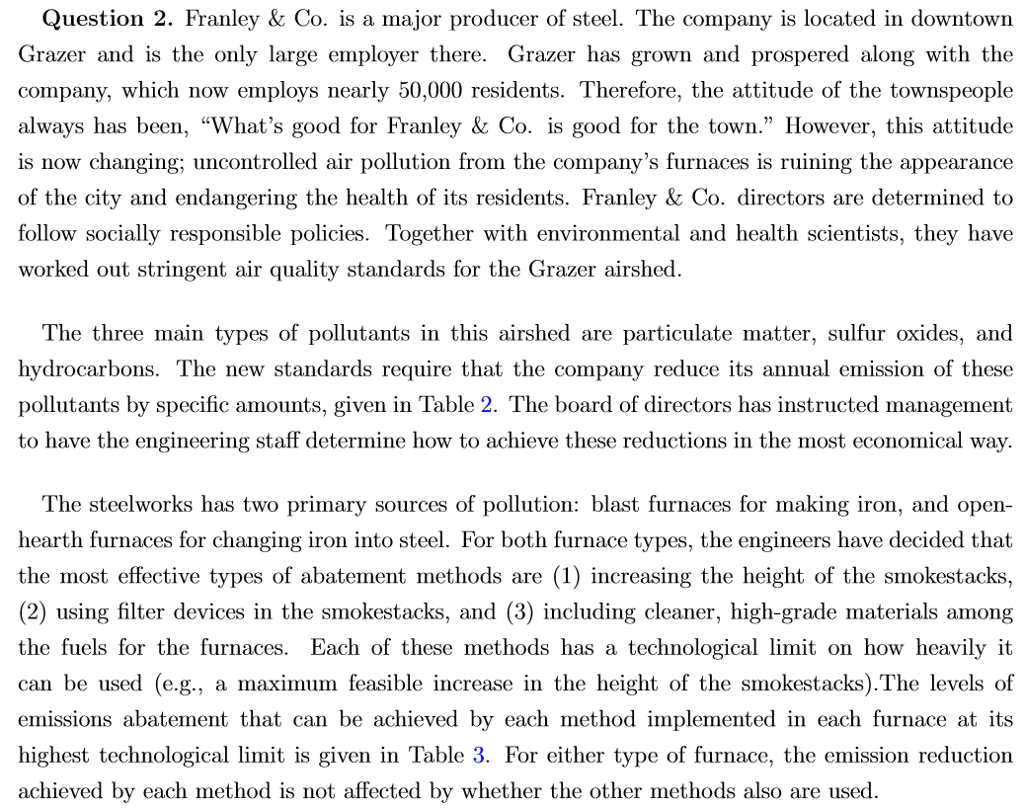

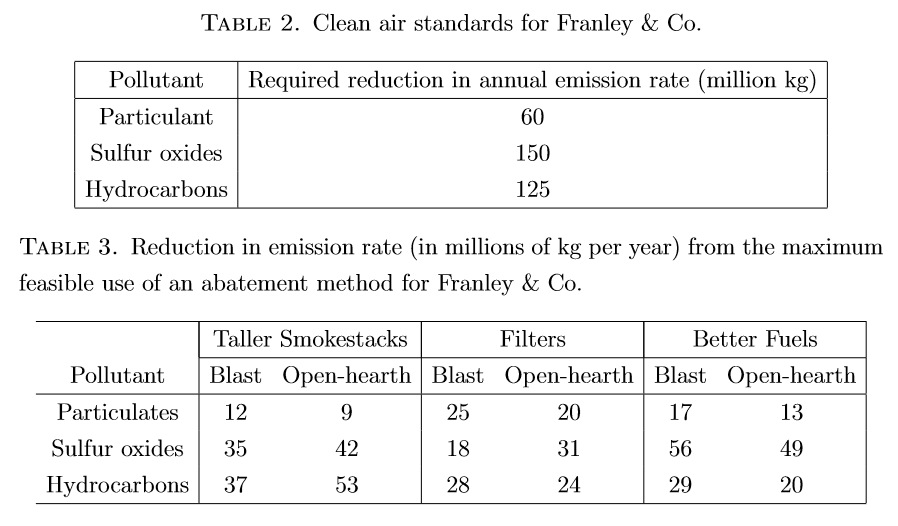

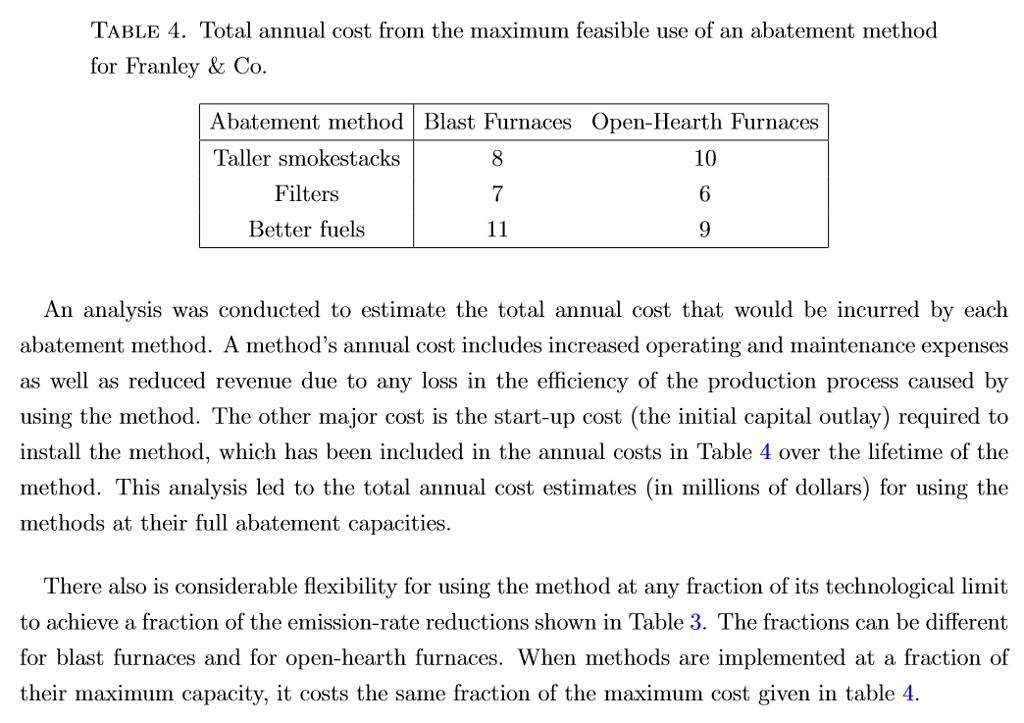

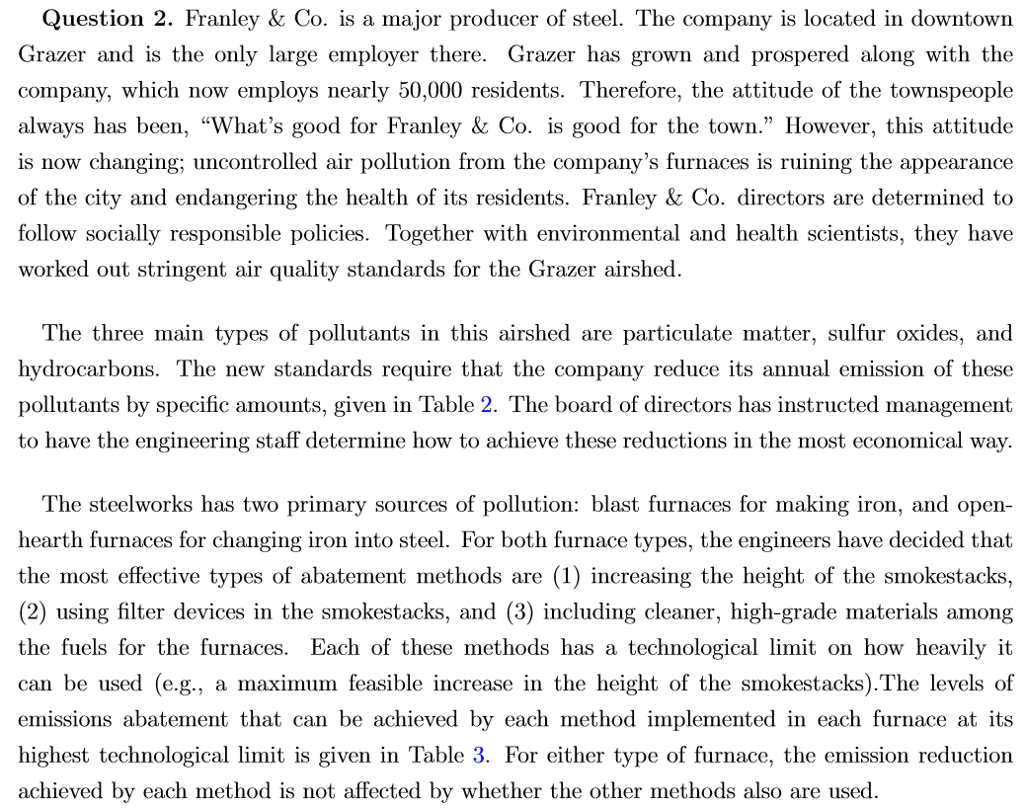

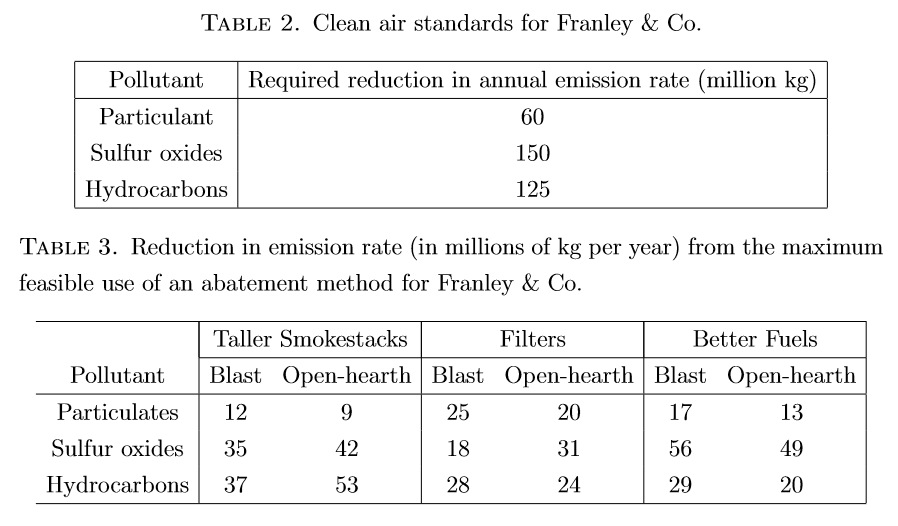

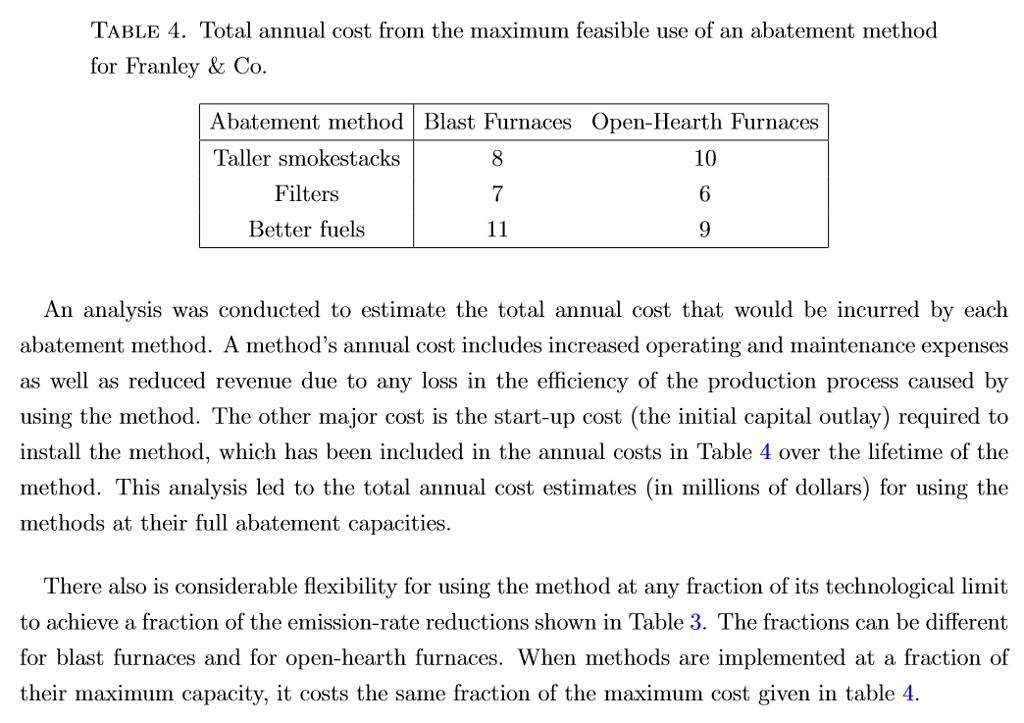

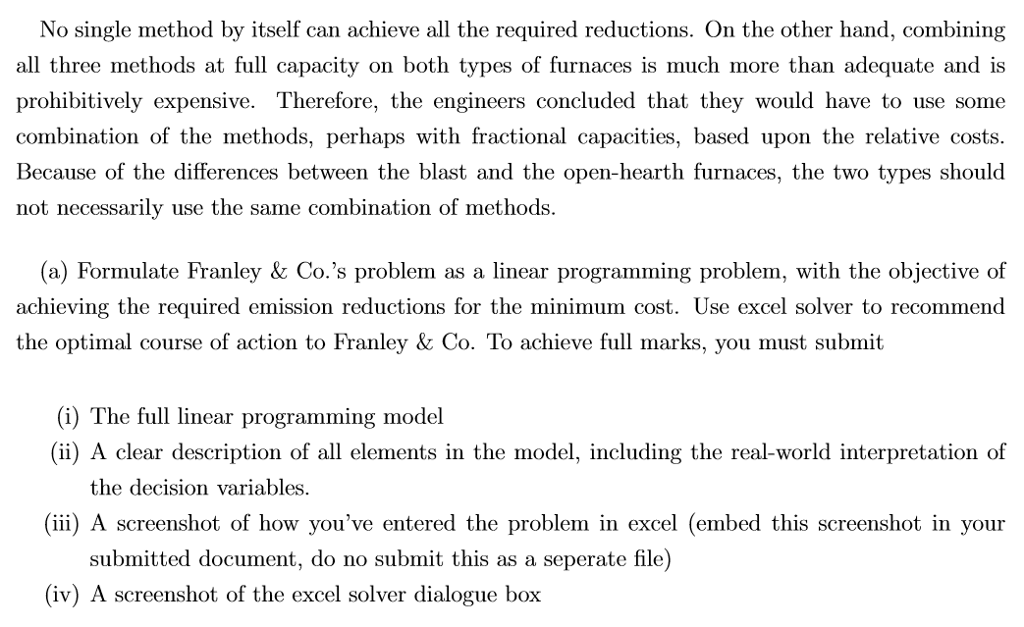

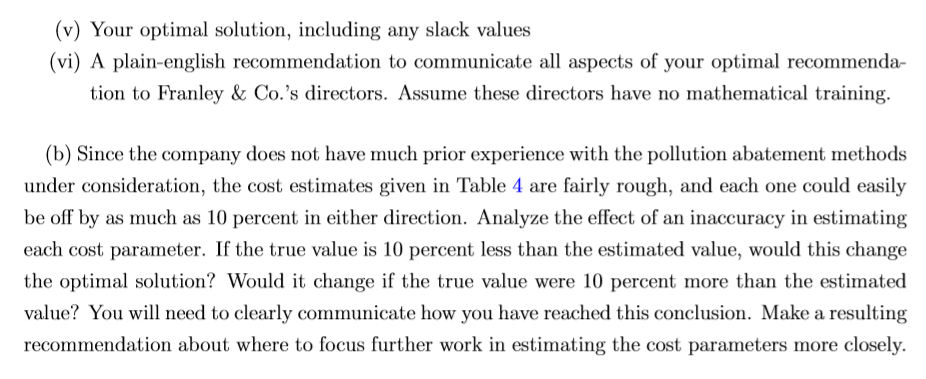

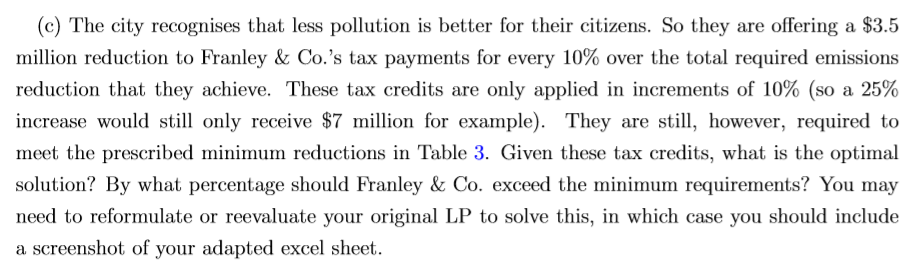

Question 2. Franley & Co. is a major producer of steel. The company is located in downtown Grazer and is the only large employer there. Grazer has grown and prospered along with the company, which now employs nearly 50,000 residents. Therefore, the attitude of the townspeople always has been, "What's good for Franley & Co. is good for the town." However, this attitude is now changing; uncontrolled air pollution from the company's furnaces is ruining the appearance of the city and endangering the health of its residents. Franley & Co. directors are determined to follow socially responsible policies. Together with environmental and health scientists, they have worked out str?ngent air quality standards for the Grazer airshed The three main types of pollutants in this airshed are particulate matter, sulfur oxides, and hydrocarbons. The new standards require that the company reduce its annual emission of these pollutants by specific amounts, given in Table 2. The board of directors has instructed management to have the engineering staff determine how to achieve these reductions in the most economical way. The steelworks has two primary sources of pollution: blast furnaces for making iron, and open- hearth furnaces for changing iron into steel. For both furnace types, the engineers have decided that the most effective types of abatement methods are (1) increasing the height of the smokestacks (2) using filter devices in the smokestacks, and (3) including cleaner, high-grade materials among the fuels for the furnaces. Each of these methods has a technological limit on how heavily it can be used (e.g., a maximum feasible increase in the height of the smokestacks).The levels of emissions abatement that can be achieved by each method implemented in each furnace at its highest technological limit is given in Table 3. For either type of furnace, the emission reduction hieved by each method is not affected by whether the other methods also are used Question 2. Franley & Co. is a major producer of steel. The company is located in downtown Grazer and is the only large employer there. Grazer has grown and prospered along with the company, which now employs nearly 50,000 residents. Therefore, the attitude of the townspeople always has been, "What's good for Franley & Co. is good for the town." However, this attitude is now changing; uncontrolled air pollution from the company's furnaces is ruining the appearance of the city and endangering the health of its residents. Franley & Co. directors are determined to follow socially responsible policies. Together with environmental and health scientists, they have worked out str?ngent air quality standards for the Grazer airshed The three main types of pollutants in this airshed are particulate matter, sulfur oxides, and hydrocarbons. The new standards require that the company reduce its annual emission of these pollutants by specific amounts, given in Table 2. The board of directors has instructed management to have the engineering staff determine how to achieve these reductions in the most economical way. The steelworks has two primary sources of pollution: blast furnaces for making iron, and open- hearth furnaces for changing iron into steel. For both furnace types, the engineers have decided that the most effective types of abatement methods are (1) increasing the height of the smokestacks (2) using filter devices in the smokestacks, and (3) including cleaner, high-grade materials among the fuels for the furnaces. Each of these methods has a technological limit on how heavily it can be used (e.g., a maximum feasible increase in the height of the smokestacks).The levels of emissions abatement that can be achieved by each method implemented in each furnace at its highest technological limit is given in Table 3. For either type of furnace, the emission reduction hieved by each method is not affected by whether the other methods also are used