Answered step by step

Verified Expert Solution

Question

1 Approved Answer

Every year millions of Canadians enjoy the flavour of ice cream. T J Conner (T J), the owner and president of Bakerview Dairies is

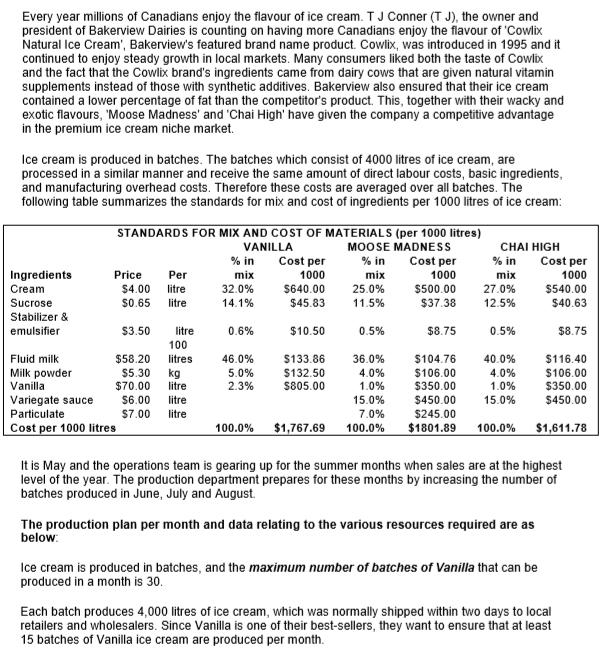

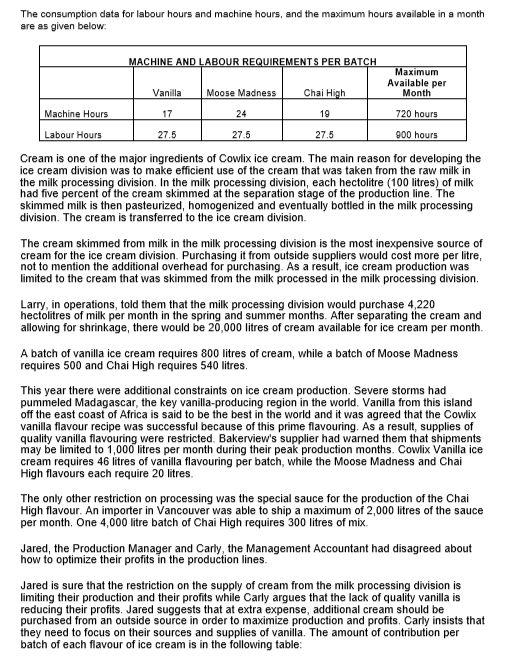

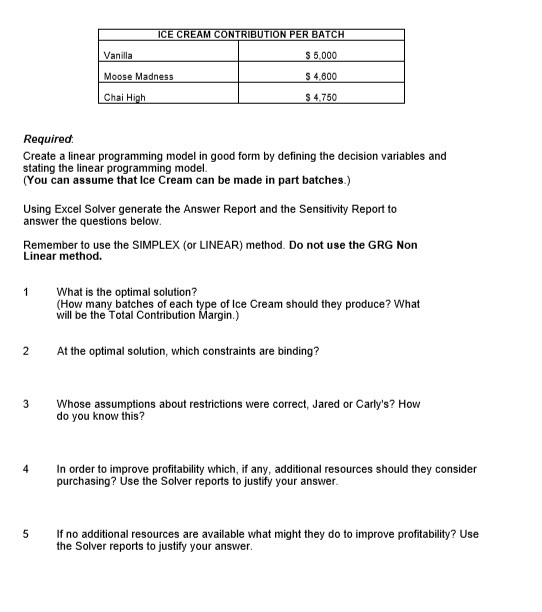

Every year millions of Canadians enjoy the flavour of ice cream. T J Conner (T J), the owner and president of Bakerview Dairies is counting on having more Canadians enjoy the flavour of 'Cowlix Natural Ice Cream', Bakerview's featured brand name product. Cowlix, was introduced in 1995 and it continued to enjoy steady growth in local markets. Many consumers liked both the taste of Cowlix and the fact that the Cowlix brand's ingredients came from dairy cows that are given natural vitamin supplements instead of those with synthetic additives. Bakerview also ensured that their ice cream contained a lower percentage of fat than the competitor's product. This, together with their wacky and exotic flavours, 'Moose Madness' and 'Chai High' have given the company a competitive advantage in the premium ice cream niche market. Ice cream is produced in batches. The batches which consist of 4000 litres of ice cream, are processed in a similar manner and receive the same amount of direct labour costs, basic ingredients, and manufacturing overhead costs. Therefore these costs are averaged over all batches. The following table summarizes the standards for mix and cost of ingredients per 1000 litres of ice cream: STANDARDS FOR MIX AND COST OF MATERIALS (per 1000 litres) VANILLA % in Cost per MOOSE MADNESS % in Cost per CHAI HIGH % in Cost per Ingredients Cream Price Per mix 1000 mix 1000 mix 1000 $4.00 litre 32.0% $640.00 25.0% $500.00 27.0% $540.00 Sucrose $0.65 litre 14.1% $45.83 11.5% $37.38 12.5% $40.63 Stabilizer & emulsifier $3.50 litre 0.6% $10.50 0.5% $8.75 0.5% $8.75 100 Fluid milk $58.20 litres 46.0% $133.86 36.0% $104.76 40.0% $116.40 Milk powder $5.30 kg 5.0% $132.50 4.0% $106.00 4.0% $106.00 Vanilla $70.00 litre 2.3% $805.00 1.0% $350.00 1.0% $350.00 Variegate sauce $6.00 litre 15.0% $450.00 15.0% $450.00 Particulate $7.00 litre 7.0% $245.00 Cost per 1000 litres 100.0% $1,767.69 100.0% $1801.89 100.0% $1,611.78 It is May and the operations team is gearing up for the summer months when sales are at the highest level of the year. The production department prepares for these months by increasing the number of batches produced in June, July and August. The production plan per month and data relating to the various resources required are as below: Ice cream is produced in batches, and the maximum number of batches of Vanilla that can be produced in a month is 30. Each batch produces 4,000 litres of ice cream, which was normally shipped within two days to local retailers and wholesalers. Since Vanilla is one of their best-sellers, they want to ensure that at least 15 batches of Vanilla ice cream are produced per month. The consumption data for labour hours and machine hours, and the maximum hours available in a month are as given below: MACHINE AND LABOUR REQUIREMENTS PER BATCH Vanilla Moose Madness Chai High Maximum Available per Month Machine Hours 17 24 19 720 hours Labour Hours 27.5 27.5 27.5 900 hours Cream is one of the major ingredients of Cowlix ice cream. The main reason for developing the ice cream division was to make efficient use of the cream that was taken from the raw milk in the milk processing division. In the milk processing division, each hectolitre (100 litres) of milk had five percent of the cream skimmed at the separation stage of the production line. The skimmed milk is then pasteurized, homogenized and eventually bottled in the milk processing division. The cream is transferred to the ice cream division. The cream skimmed from milk in the milk processing division is the most inexpensive source of cream for the ice cream division. Purchasing it from outside suppliers would cost more per litre, not to mention the additional overhead for purchasing. As a result, ice cream production was limited to the cream that was skimmed from the milk processed in the milk processing division. Larry, in operations, told them that the milk processing division would purchase 4,220 hectolitres of milk per month in the spring and summer months. After separating the cream and allowing for shrinkage, there would be 20,000 litres of cream available for ice cream per month. A batch of vanilla ice cream requires 800 litres of cream, while a batch of Moose Madness requires 500 and Chai High requires 540 litres. This year there were additional constraints on ice cream production. Severe storms had pummeled Madagascar, the key vanilla-producing region in the world. Vanilla from this island off the east coast of Africa is said to be the best in the world and it was agreed that the Cowlix vanilla flavour recipe was successful because of this prime flavouring. As a result, supplies of quality vanilla flavouring were restricted. Bakerview's supplier had warned them that shipments may be limited to 1,000 litres per month during their peak production months. Cowlix Vanilla ice cream requires 46 litres of vanilla flavouring per batch, while the Moose Madness and Chai High flavours each require 20 litres. The only other restriction on processing was the special sauce for the production of the Chai High flavour. An importer in Vancouver was able to ship a maximum of 2,000 litres of the sauce per month. One 4,000 litre batch of Chai High requires 300 litres of mix. Jared, the Production Manager and Carly, the Management Accountant had disagreed about how to optimize their profits in the production lines. Jared is sure that the restriction on the supply of cream from the milk processing division is limiting their production and their profits while Carly argues that the lack of quality vanilla is reducing their profits. Jared suggests that at extra expense, additional cream should be purchased from an outside source in order to maximize production and profits. Carly insists that they need to focus on their sources and supplies of vanilla. The amount of contribution per batch of each flavour of ice cream is in the following table: Vanilla ICE CREAM CONTRIBUTION PER BATCH Moose Madness Chai High $ 5,000 $ 4,000 $4,750 Required Create a linear programming model in good form by defining the decision variables and stating the linear programming model. (You can assume that Ice Cream can be made in part batches.) Using Excel Solver generate the Answer Report and the Sensitivity Report to answer the questions below. Remember to use the SIMPLEX (or LINEAR) method. Do not use the GRG Non Linear method. 1 What is the optimal solution? 2 (How many batches of each type of Ice Cream should they produce? What will be the Total Contribution Margin.) At the optimal solution, which constraints are binding? 3 Whose assumptions about restrictions were correct, Jared or Carly's? How do you know this? 4 In order to improve profitability which, if any, additional resources should they consider purchasing? Use the Solver reports to justify your answer. 5 If no additional resources are available what might they do to improve profitability? Use the Solver reports to justify your answer.

Step by Step Solution

There are 3 Steps involved in it

Step: 1

Get Instant Access to Expert-Tailored Solutions

See step-by-step solutions with expert insights and AI powered tools for academic success

Step: 2

Step: 3

Ace Your Homework with AI

Get the answers you need in no time with our AI-driven, step-by-step assistance

Get Started