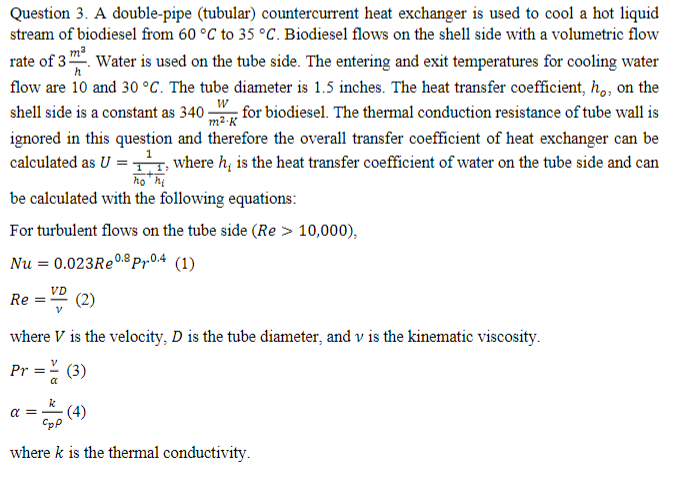

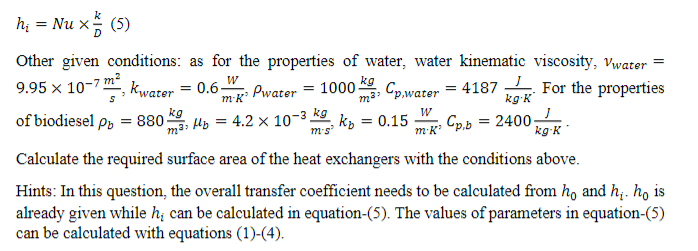

Question 3. A double-pipe (tubular) countercurrent heat exchanger is used to cool a hot liquid stream of biodiesel from 60 C to 35 C. Biodiesel flows on the shell side with a volumetric flow rate of 3 mWater is used on the tube side. The entering and exit temperatures for cooling water flow are 10 and 30 C. The tube diameter is 1.5 inches. The heat transfer coefficient, ho, on the shell side is a constant as 340 max for biodiesel. The thermal conduction resistance of tube wall is ignored in this question and therefore the overall transfer coefficient of heat exchanger can be calculated as U = 111, where h is the heat transfer coefficient of water on the tube side and can no hi be calculated with the following equations: For turbulent flows on the tube side (Re> 0), Nu = 0.023 Re0.8 pp.0.4 (1) VD Re (2) V where V is the velocity, D is the tube diameter, and v is the kinematic viscosity. Pr (3) a = reno (4) Cpp where k is the thermal conductivity. = = 9.95 x 10-7 m2 = 1000 kg m. m3 W h = Nu x6 (5) Other given conditions: as for the properties of water, water kinematic viscosity, Vwater kwater = 0.6 W Pwater Cp,water = 4187 For the properties kg K kg of biodiesel pb = 880 mas lo = 4.2 x 10-3 kg, kp = 0.15 1 Cpb = 2400 kg K Calculate the required surface area of the heat exchangers with the conditions above. Hints: In this question, the overall transfer coefficient needs to be calculated from h, and hi. ho is already given while hi can be calculated in equation-(5). The values of parameters in equation-(5) can be calculated with equations (1)-(4). m.R Question 3. A double-pipe (tubular) countercurrent heat exchanger is used to cool a hot liquid stream of biodiesel from 60 C to 35 C. Biodiesel flows on the shell side with a volumetric flow rate of 3 mWater is used on the tube side. The entering and exit temperatures for cooling water flow are 10 and 30 C. The tube diameter is 1.5 inches. The heat transfer coefficient, ho, on the shell side is a constant as 340 max for biodiesel. The thermal conduction resistance of tube wall is ignored in this question and therefore the overall transfer coefficient of heat exchanger can be calculated as U = 111, where h is the heat transfer coefficient of water on the tube side and can no hi be calculated with the following equations: For turbulent flows on the tube side (Re> 0), Nu = 0.023 Re0.8 pp.0.4 (1) VD Re (2) V where V is the velocity, D is the tube diameter, and v is the kinematic viscosity. Pr (3) a = reno (4) Cpp where k is the thermal conductivity. = = 9.95 x 10-7 m2 = 1000 kg m. m3 W h = Nu x6 (5) Other given conditions: as for the properties of water, water kinematic viscosity, Vwater kwater = 0.6 W Pwater Cp,water = 4187 For the properties kg K kg of biodiesel pb = 880 mas lo = 4.2 x 10-3 kg, kp = 0.15 1 Cpb = 2400 kg K Calculate the required surface area of the heat exchangers with the conditions above. Hints: In this question, the overall transfer coefficient needs to be calculated from h, and hi. ho is already given while hi can be calculated in equation-(5). The values of parameters in equation-(5) can be calculated with equations (1)-(4). m.R