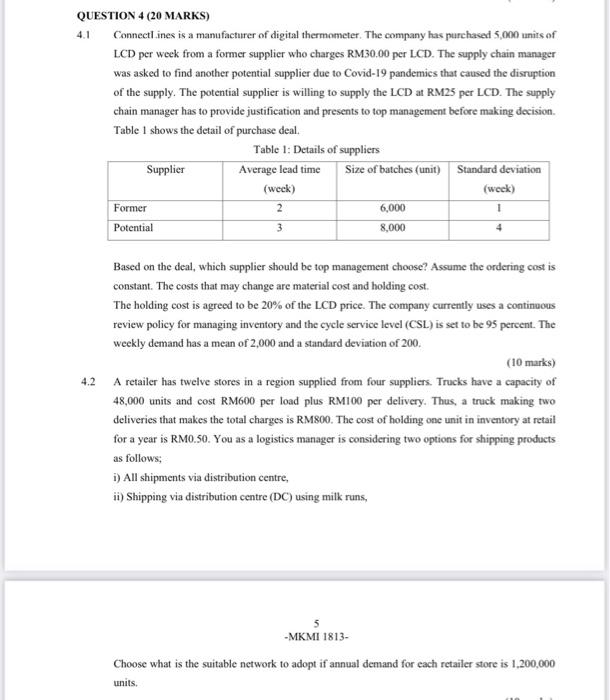

QUESTION 4 (20 MARKS) Connectlines is a manufacturer of digital thermometer. The company has purchased 5,000 units of LCD per week from a former supplier who charges RM30.00 per LCD. The supply chain manager was asked to find another potential supplier due to Covid-19 pandemics that caused the disruption of the supply. The potential supplier is willing to supply the LCD at RM25 per LCD. The supply chain manager has to provide justification and presents to top management before making decision Table 1 shows the detail of purchase deal. Table 1: Details of suppliers Supplier Average lead time Size of batches (unit) Standard deviation (weck) (week) Former 6,000 Potential 8,000 2 1 3 4 4.2 Based on the deal, which supplier should be top management choose? Assume the ordering cost is constant. The costs that may change are material cost and holding cost. The holding cost is agreed to be 20% of the LCD price. The company currently uses a continuous review policy for managing inventory and the cycle service level (CSL) is set to be 95 percent. The weekly demand has a mean of 2,000 and a standard deviation of 200. (10 marks) A retailer has twelve stores in a region supplied from four suppliers. Trucks have a capacity of 48,000 units and cost RM600 per load plus RM100 per delivery. Thus, a truck making two deliveries that makes the total charges is RM800. The cost of holding one unit in inventory at retail for a year is RM0.50. You as a logistics manager is considering two options for shipping products as follows: i) All shipments via distribution centre, ii) Shipping via distribution centre (DC) using milk runs, -MKMI 1813- Choose what is the suitable network to adopt if annual demand for each retailer store is 1.200,000 units. QUESTION 4 (20 MARKS) Connectlines is a manufacturer of digital thermometer. The company has purchased 5,000 units of LCD per week from a former supplier who charges RM30.00 per LCD. The supply chain manager was asked to find another potential supplier due to Covid-19 pandemics that caused the disruption of the supply. The potential supplier is willing to supply the LCD at RM25 per LCD. The supply chain manager has to provide justification and presents to top management before making decision Table 1 shows the detail of purchase deal. Table 1: Details of suppliers Supplier Average lead time Size of batches (unit) Standard deviation (weck) (week) Former 6,000 Potential 8,000 2 1 3 4 4.2 Based on the deal, which supplier should be top management choose? Assume the ordering cost is constant. The costs that may change are material cost and holding cost. The holding cost is agreed to be 20% of the LCD price. The company currently uses a continuous review policy for managing inventory and the cycle service level (CSL) is set to be 95 percent. The weekly demand has a mean of 2,000 and a standard deviation of 200. (10 marks) A retailer has twelve stores in a region supplied from four suppliers. Trucks have a capacity of 48,000 units and cost RM600 per load plus RM100 per delivery. Thus, a truck making two deliveries that makes the total charges is RM800. The cost of holding one unit in inventory at retail for a year is RM0.50. You as a logistics manager is considering two options for shipping products as follows: i) All shipments via distribution centre, ii) Shipping via distribution centre (DC) using milk runs, -MKMI 1813- Choose what is the suitable network to adopt if annual demand for each retailer store is 1.200,000 units