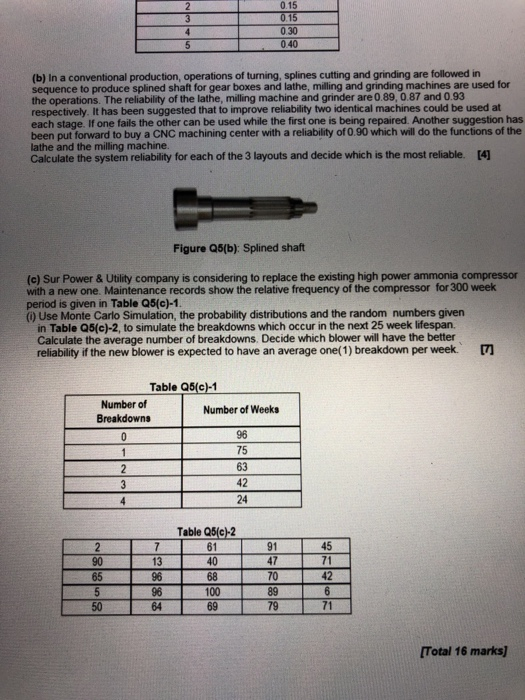

Question 5: (a) For a compressor the probability of failure occurring during a given week is given in Table Q5(a) Calculate the Annual Breakdown Maintenance Costs (where no Preventive Maintenance is carried out). The costs are 300 OMR to repair the compressor, every time it fails. (m) Preventive maintenance costs 60 OMR for each service. Calculate if Preventive Maintenance is cheaper than Breakdown Maintenance, and if so how often Preventive Maintenance should be carried out. There are 48 working weeks in a year. [2] Table Q5(a) Week of Operation Probability of failure during the given week 1 0.00 0.15 0.15 2 3 4 5 030 0.40 (b) In a conventional production, operations of turning, splines cutting and grinding are followed in sequence to produce splined shaft for gear boxes and lathe, milling and grinding machines are used for the operations. The reliability of the lathe, milling machine and grinder are 0.89, 0.87 and 0.93 respectively. It has been suggested that to improve reliability two identical machines could be used at each stage. If one fails the other can be used while the first one is being repaired. Another suggestion has been put forward to buy a CNC machining center with a reliability of 0.90 which will do the functions of the lathe and the milling machine Calculate the system reliability for each of the 3 layouts and decide which is the most reliable. [4] Figure Q5(b): Splined shaft (c) Sur Power & Utility company is considering to replace the existing high power ammonia compressor with a new one. Maintenance records show the relative frequency of the compressor for 300 week period is given in Table Q5(c)-1. Use Monte Carlo Simulation, the probability distributions and the random numbers given in Table Q5(c)-2, to simulate the breakdowns which occur in the next 25 week lifespan. Calculate the average number of breakdowns. Decide which blower will have the better reliability if the new blower is expected to have an average one(1) breakdown per week Table 26(c)-1 Number of Number of Weeks Breakdowns 0 96 75 2 63 3 42 4 24 1 2 3 4 5 0.15 0.15 0.30 0.40 (b) In a conventional production, operations of turning, splines cutting and grinding are followed in sequence to produce splined shaft for gear boxes and lathe, milling and grinding machines are used for the operations. The reliability of the lathe, milling machine and grinder are 0.89, 0.87 and 0.93 respectively. It has been suggested that to improve reliability to identical machines could be used at each stage. If one fails the other can be used while the first one is being repaired. Another suggestion has been put forward to buy a CNC machining center with a reliability of 0.90 which will do the functions of the lathe and the milling machine Calculate the system reliability for each of the 3 layouts and decide which is the most reliable. [4 Figure Q5(b): Splined shaft (c) Sur Power & Utility company is considering to replace the existing high power ammonia compressor with a new one. Maintenance records show the relative frequency of the compressor for 300 week period is given in Table Q5(c)-1. (Use Monte Carlo Simulation, the probability distributions and the random numbers given in Table Q5(c)-2, to simulate the breakdowns which occur in the next 25 week lifespan. Calculate the average number of breakdowns. Decide which blower will have the better reliability if the new blower is expected to have an average one(1) breakdown per week. 17 Table Q5(c)-1 Number of Number of Weeks Breakdowns 0 96 75 2 63 3 42 4 24 1 2 90 65 5 50 7 13 96 96 64 Table Q5(c)-2 61 40 68 100 69 91 47 70 89 79 45 71 42 6 71 [Total 16 marks) Question 5: (a) For a compressor the probability of failure occurring during a given week is given in Table Q5(a) Calculate the Annual Breakdown Maintenance Costs (where no Preventive Maintenance is carried out). The costs are 300 OMR to repair the compressor, every time it fails. (m) Preventive maintenance costs 60 OMR for each service. Calculate if Preventive Maintenance is cheaper than Breakdown Maintenance, and if so how often Preventive Maintenance should be carried out. There are 48 working weeks in a year. [2] Table Q5(a) Week of Operation Probability of failure during the given week 1 0.00 0.15 0.15 2 3 4 5 030 0.40 (b) In a conventional production, operations of turning, splines cutting and grinding are followed in sequence to produce splined shaft for gear boxes and lathe, milling and grinding machines are used for the operations. The reliability of the lathe, milling machine and grinder are 0.89, 0.87 and 0.93 respectively. It has been suggested that to improve reliability two identical machines could be used at each stage. If one fails the other can be used while the first one is being repaired. Another suggestion has been put forward to buy a CNC machining center with a reliability of 0.90 which will do the functions of the lathe and the milling machine Calculate the system reliability for each of the 3 layouts and decide which is the most reliable. [4] Figure Q5(b): Splined shaft (c) Sur Power & Utility company is considering to replace the existing high power ammonia compressor with a new one. Maintenance records show the relative frequency of the compressor for 300 week period is given in Table Q5(c)-1. Use Monte Carlo Simulation, the probability distributions and the random numbers given in Table Q5(c)-2, to simulate the breakdowns which occur in the next 25 week lifespan. Calculate the average number of breakdowns. Decide which blower will have the better reliability if the new blower is expected to have an average one(1) breakdown per week Table 26(c)-1 Number of Number of Weeks Breakdowns 0 96 75 2 63 3 42 4 24 1 2 3 4 5 0.15 0.15 0.30 0.40 (b) In a conventional production, operations of turning, splines cutting and grinding are followed in sequence to produce splined shaft for gear boxes and lathe, milling and grinding machines are used for the operations. The reliability of the lathe, milling machine and grinder are 0.89, 0.87 and 0.93 respectively. It has been suggested that to improve reliability to identical machines could be used at each stage. If one fails the other can be used while the first one is being repaired. Another suggestion has been put forward to buy a CNC machining center with a reliability of 0.90 which will do the functions of the lathe and the milling machine Calculate the system reliability for each of the 3 layouts and decide which is the most reliable. [4 Figure Q5(b): Splined shaft (c) Sur Power & Utility company is considering to replace the existing high power ammonia compressor with a new one. Maintenance records show the relative frequency of the compressor for 300 week period is given in Table Q5(c)-1. (Use Monte Carlo Simulation, the probability distributions and the random numbers given in Table Q5(c)-2, to simulate the breakdowns which occur in the next 25 week lifespan. Calculate the average number of breakdowns. Decide which blower will have the better reliability if the new blower is expected to have an average one(1) breakdown per week. 17 Table Q5(c)-1 Number of Number of Weeks Breakdowns 0 96 75 2 63 3 42 4 24 1 2 90 65 5 50 7 13 96 96 64 Table Q5(c)-2 61 40 68 100 69 91 47 70 89 79 45 71 42 6 71 [Total 16 marks)