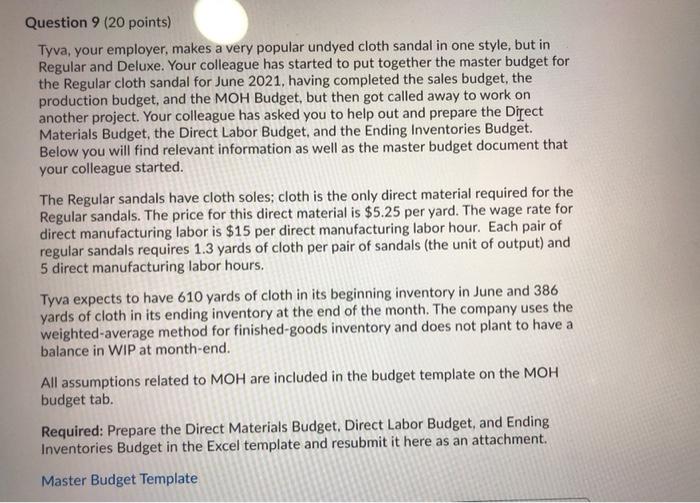

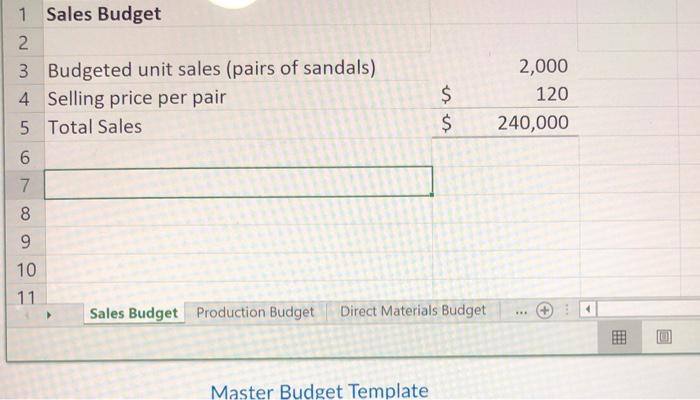

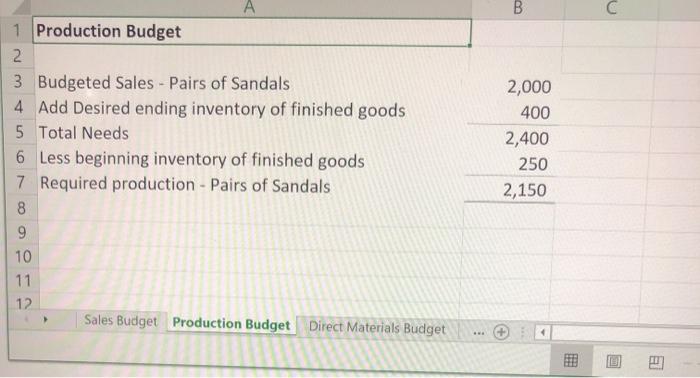

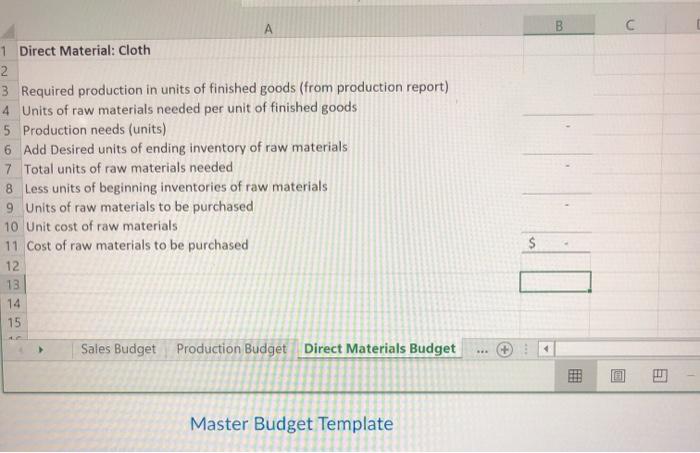

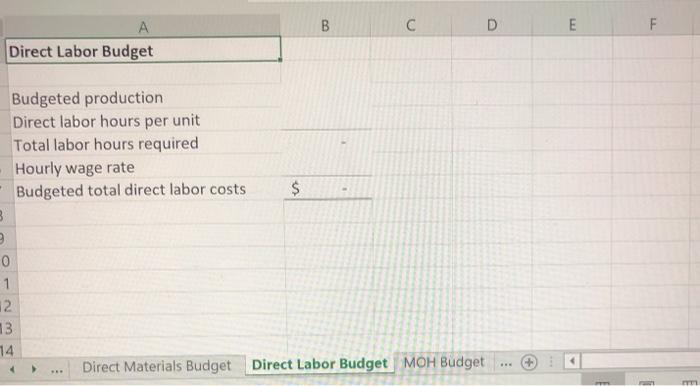

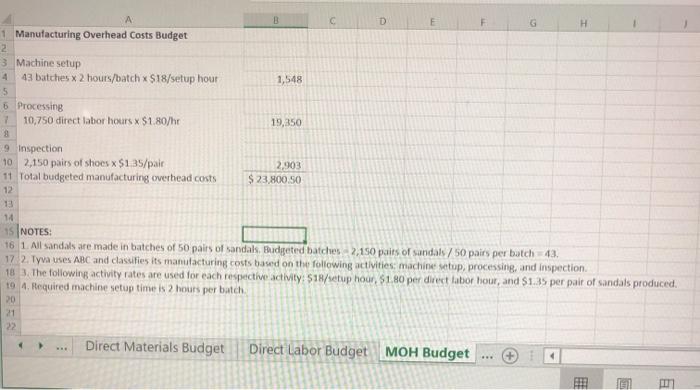

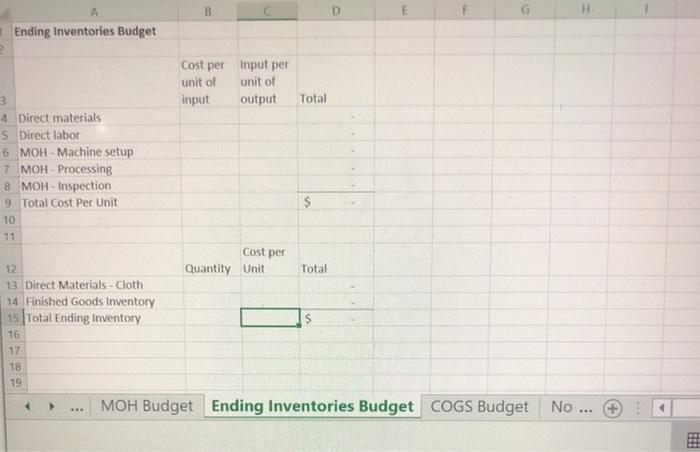

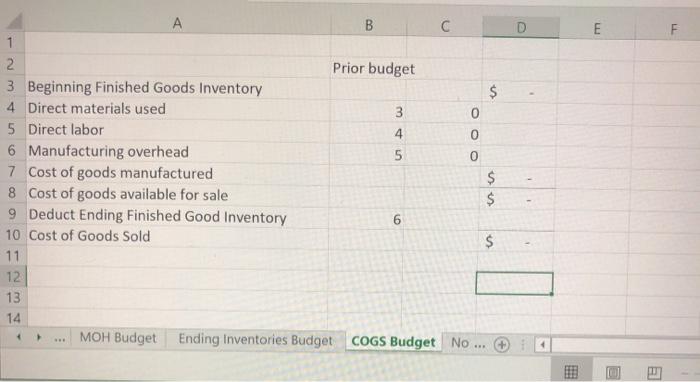

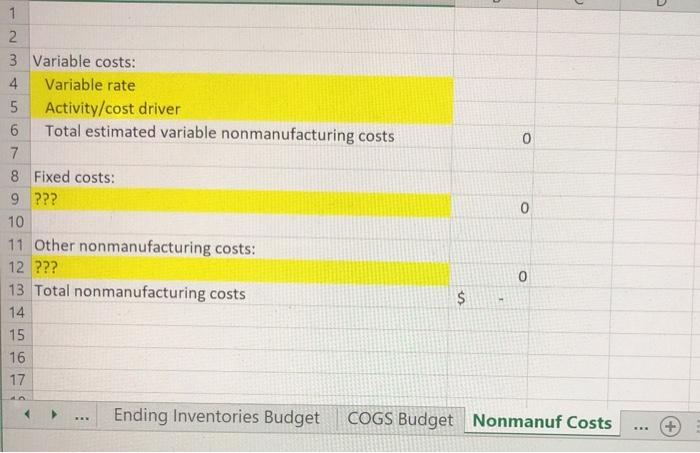

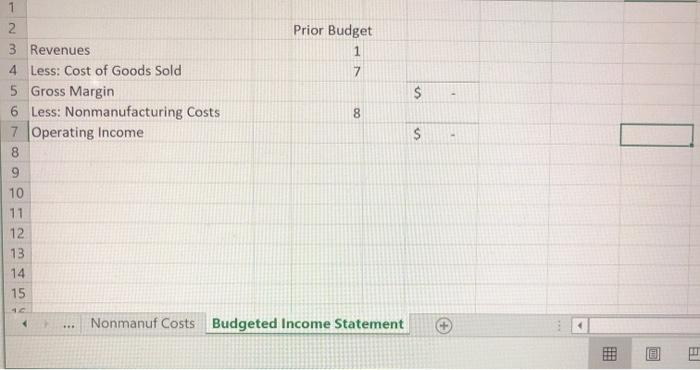

Question 9 (20 points) Tyva, your employer, makes a very popular undyed cloth sandal in one style, but in Regular and Deluxe. Your colleague has started to put together the master budget for the Regular cloth sandal for June 2021, having completed the sales budget, the production budget, and the MOH Budget, but then got called away to work on another project. Your colleague has asked you to help out and prepare the Direct Materials Budget, the Direct Labor Budget, and the Ending Inventories Budget. Below you will find relevant information as well as the master budget document that your colleague started. The Regular sandals have cloth soles; cloth is the only direct material required for the Regular sandals. The price for this direct material is $5.25 per yard. The wage rate for direct manufacturing labor is $15 per direct manufacturing labor hour. Each pair of regular sandals requires 1.3 yards of cloth per pair of sandals (the unit of output) and 5 direct manufacturing labor hours. Tyva expects to have 610 yards of cloth in its beginning inventory in June and 386 yards of cloth in its ending inventory at the end of the month. The company uses the weighted average method for finished-goods inventory and does not plant to have a balance in WIP at month-end. All assumptions related to MOH are included in the budget template on the MOH budget tab. Required: Prepare the Direct Materials Budget, Direct Labor Budget, and Ending Inventories Budget in the Excel template and resubmit it here as an attachment. Master Budget Template 1 Sales Budget 2 3 Budgeted unit sales (pairs of sandals) 4 Selling price per pair 5 Total Sales 6 $ $ 2,000 120 240,000 7 9 8 9 10 11 Sales Budget Production Budget Direct Materials Budget Master Budget Template B 1 Production Budget 2 3 Budgeted Sales - Pairs of Sandals 4 Add Desired ending inventory of finished goods 5 Total Needs 6 Less beginning inventory of finished goods 7 Required production - Pairs of Sandals 8 9 10 11 12 Sales Budget Production Budget Direct Materials Budget 2,000 400 2,400 250 2,150 B c 1 Direct Material: Cloth 2 3 Required production in units of finished goods (from production report) 4 Units of raw materials needed per unit of finished goods 5 Production needs (units) 6 Add Desired units of ending inventory of raw materials 7 Total units of raw materials needed 8 Less units of beginning inventories of raw materials 9 Units of raw materials to be purchased 10 Unit cost of raw materials 11 Cost of raw materials to be purchased 12 $ 13 14 15 Sales Budget Production Budget Direct Materials Budget CH IS Master Budget Template B C D E F A Direct Labor Budget Budgeted production Direct labor hours per unit Total labor hours required - Hourly wage rate Budgeted total direct labor costs 3 - $ 0 1 12 13 14 Direct Materials Budget Direct Labor Budget MOH Budget B c D F F H 1 Manufacturing Overhead Costs Budget 2 3 Machine setup 4 43 batches x 2 hours/batch $18/setup hour 1,548 6 Processing 7 10,750 direct labor hours x $1.80/ht 19,350 9 Inspection 102,150 pairs of shoes x $135/pale 2,103 11 Total budgeted manufacturing overhead costs $ 23 800.50 12 13 14 15 NOTES: 16 1. All sandals are made in batches of 50 pairs of sandals, Budgeted batches 2,150 paits of sandals / 50 pairs per batch 43. 17 2. Tyva uses ABC and classifies its manufacturing costs based on the following activities machine setup, processing and inspection 18 3. The following activity rates are used for each respective activity: 518/setup hour, 51.80 per direct labor hour, and $1.35 per pair of sandals produced 19 4. Required machine setup time is 2 hours per batch 20 21 22 Direct Materials Budget Direct Labor Budget MOH Budget E B D E LL Prior budget $ 3 4 A 1 2 3 Beginning Finished Goods Inventory 4 Direct materials used 5 Direct labor 6 Manufacturing overhead 7 Cost of goods manufactured 8 Cost of goods available for sale 9 Deduct Ending Finished Good Inventory 10 Cost of Goods Sold 11 12 13 OOO un 5 $ $ 6 $ - 14 BB MOH Budget Ending Inventories Budget COGS Budget No ... + 0 1 2 3 Variable costs: 4 Variable rate 5 Activity/cost driver 6 Total estimated variable nonmanufacturing costs 7 8 Fixed costs: 9 ??? 10 11 Other nonmanufacturing costs: 12 ??? 13 Total nonmanufacturing costs 14 15 16 17 0 0 $ Ending Inventories Budget COGS Budget Nonmanuf Costs Prior Budget 1 7 $ $ - 8 $ 1 2 3 Revenues 4 Less: Cost of Goods Sold 5 Gross Margin 6 Less: Nonmanufacturing Costs 7 Operating Income 8 9 10 11 12 13 14 15 . Nonmanuf Costs Budgeted Income Statement + Question 9 (20 points) Tyva, your employer, makes a very popular undyed cloth sandal in one style, but in Regular and Deluxe. Your colleague has started to put together the master budget for the Regular cloth sandal for June 2021, having completed the sales budget, the production budget, and the MOH Budget, but then got called away to work on another project. Your colleague has asked you to help out and prepare the Direct Materials Budget, the Direct Labor Budget, and the Ending Inventories Budget. Below you will find relevant information as well as the master budget document that your colleague started. The Regular sandals have cloth soles; cloth is the only direct material required for the Regular sandals. The price for this direct material is $5.25 per yard. The wage rate for direct manufacturing labor is $15 per direct manufacturing labor hour. Each pair of regular sandals requires 1.3 yards of cloth per pair of sandals (the unit of output) and 5 direct manufacturing labor hours. Tyva expects to have 610 yards of cloth in its beginning inventory in June and 386 yards of cloth in its ending inventory at the end of the month. The company uses the weighted average method for finished-goods inventory and does not plant to have a balance in WIP at month-end. All assumptions related to MOH are included in the budget template on the MOH budget tab. Required: Prepare the Direct Materials Budget, Direct Labor Budget, and Ending Inventories Budget in the Excel template and resubmit it here as an attachment. Master Budget Template 1 Sales Budget 2 3 Budgeted unit sales (pairs of sandals) 4 Selling price per pair 5 Total Sales 6 $ $ 2,000 120 240,000 7 9 8 9 10 11 Sales Budget Production Budget Direct Materials Budget Master Budget Template B 1 Production Budget 2 3 Budgeted Sales - Pairs of Sandals 4 Add Desired ending inventory of finished goods 5 Total Needs 6 Less beginning inventory of finished goods 7 Required production - Pairs of Sandals 8 9 10 11 12 Sales Budget Production Budget Direct Materials Budget 2,000 400 2,400 250 2,150 B c 1 Direct Material: Cloth 2 3 Required production in units of finished goods (from production report) 4 Units of raw materials needed per unit of finished goods 5 Production needs (units) 6 Add Desired units of ending inventory of raw materials 7 Total units of raw materials needed 8 Less units of beginning inventories of raw materials 9 Units of raw materials to be purchased 10 Unit cost of raw materials 11 Cost of raw materials to be purchased 12 $ 13 14 15 Sales Budget Production Budget Direct Materials Budget CH IS Master Budget Template B C D E F A Direct Labor Budget Budgeted production Direct labor hours per unit Total labor hours required - Hourly wage rate Budgeted total direct labor costs 3 - $ 0 1 12 13 14 Direct Materials Budget Direct Labor Budget MOH Budget B c D F F H 1 Manufacturing Overhead Costs Budget 2 3 Machine setup 4 43 batches x 2 hours/batch $18/setup hour 1,548 6 Processing 7 10,750 direct labor hours x $1.80/ht 19,350 9 Inspection 102,150 pairs of shoes x $135/pale 2,103 11 Total budgeted manufacturing overhead costs $ 23 800.50 12 13 14 15 NOTES: 16 1. All sandals are made in batches of 50 pairs of sandals, Budgeted batches 2,150 paits of sandals / 50 pairs per batch 43. 17 2. Tyva uses ABC and classifies its manufacturing costs based on the following activities machine setup, processing and inspection 18 3. The following activity rates are used for each respective activity: 518/setup hour, 51.80 per direct labor hour, and $1.35 per pair of sandals produced 19 4. Required machine setup time is 2 hours per batch 20 21 22 Direct Materials Budget Direct Labor Budget MOH Budget E B D E LL Prior budget $ 3 4 A 1 2 3 Beginning Finished Goods Inventory 4 Direct materials used 5 Direct labor 6 Manufacturing overhead 7 Cost of goods manufactured 8 Cost of goods available for sale 9 Deduct Ending Finished Good Inventory 10 Cost of Goods Sold 11 12 13 OOO un 5 $ $ 6 $ - 14 BB MOH Budget Ending Inventories Budget COGS Budget No ... + 0 1 2 3 Variable costs: 4 Variable rate 5 Activity/cost driver 6 Total estimated variable nonmanufacturing costs 7 8 Fixed costs: 9 ??? 10 11 Other nonmanufacturing costs: 12 ??? 13 Total nonmanufacturing costs 14 15 16 17 0 0 $ Ending Inventories Budget COGS Budget Nonmanuf Costs Prior Budget 1 7 $ $ - 8 $ 1 2 3 Revenues 4 Less: Cost of Goods Sold 5 Gross Margin 6 Less: Nonmanufacturing Costs 7 Operating Income 8 9 10 11 12 13 14 15 . Nonmanuf Costs Budgeted Income Statement +