Answered step by step

Verified Expert Solution

Question

1 Approved Answer

Question a to g using the following picture Monosodium Glutamate ( MSG ) is a flavor enhancing ingredient in tomato, cheese and meat and forms

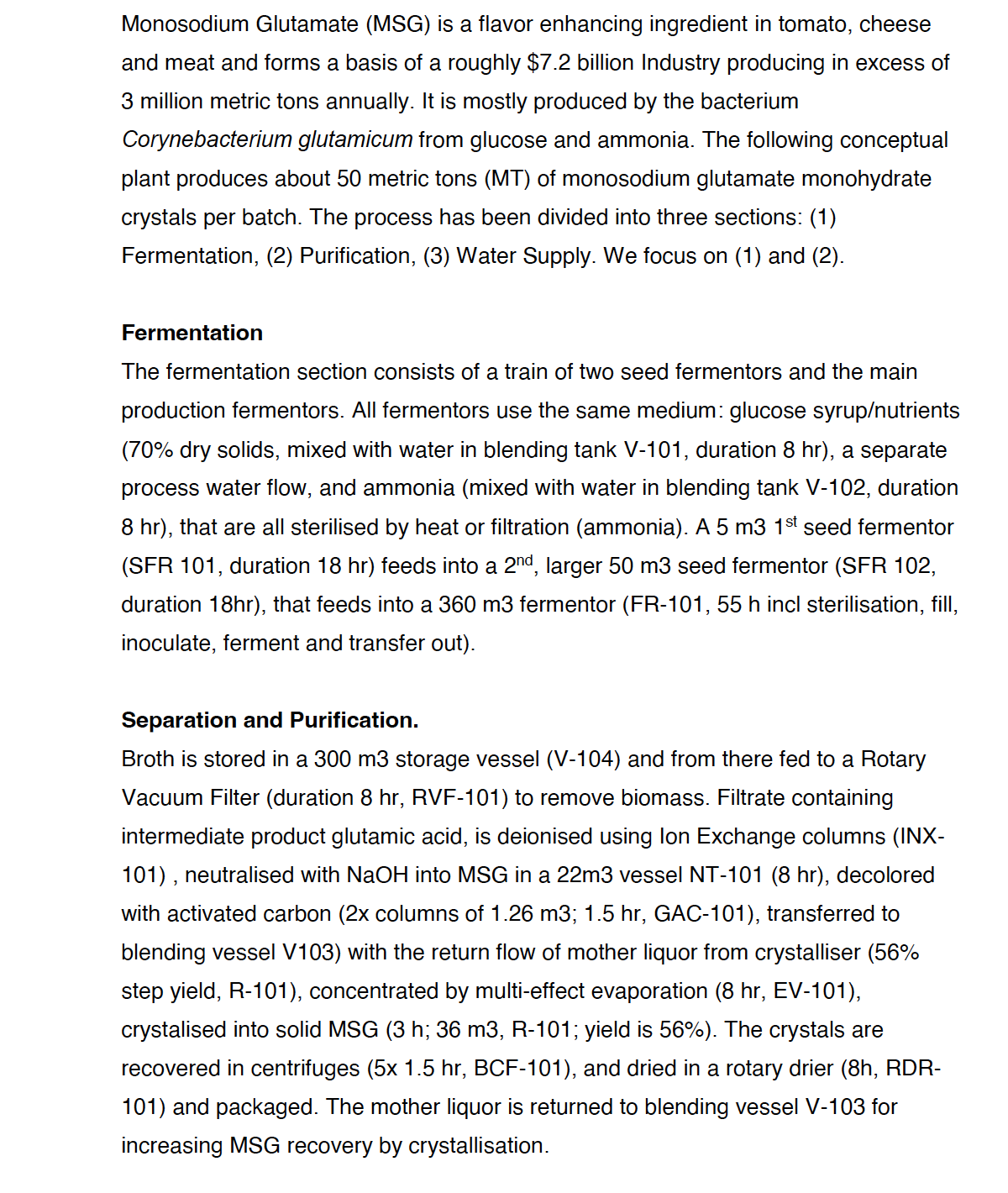

Question a to g using the following picture Monosodium Glutamate MSG is a flavor enhancing ingredient in tomato, cheese

and meat and forms a basis of a roughly $ billion Industry producing in excess of

million metric tons annually. It is mostly produced by the bacterium

Corynebacterium glutamicum from glucose and ammonia. The following conceptual

plant produces about metric tons MT of monosodium glutamate monohydrate

crystals per batch. The process has been divided into three sections:

Fermentation, Purification, Water Supply. We focus on and

Fermentation

The fermentation section consists of a train of two seed fermentors and the main

production fermentors. All fermentors use the same medium: glucose syrupnutrients

dry solids, mixed with water in blending tank V duration a separate

process water flow, and ammonia mixed with water in blending tank duration

that are all sterilised by heat or filtration ammonia A seed fermentor

SFR duration feeds into a larger seed fermentor SFR

duration hr that feeds into a fermentor FR incl sterilisation, fill,

inoculate, ferment and transfer out

Separation and Purification.

Broth is stored in a storage vessel V and from there fed to a Rotary

Vacuum Filter duration RVF to remove biomass. Filtrate containing

intermediate product glutamic acid, is deionised using lon Exchange columns INX

neutralised with NaOH into MSG in a vessel NT hr decolored

with activated carbon columns of ; GAC transferred to

blending vessel V with the return flow of mother liquor from crystalliser

step yield, R concentrated by multieffect evaporation hr EV

crystalised into solid MSG ;; yield is The crystals are

recovered in centrifuges and dried in a rotary drier RDR

and packaged. The mother liquor is returned to blending vessel V for

increasing MSG recovery by crystallisation.

a Draft a block diagram, perform a Critical Path

Analysis, and construct a Gantt Chart of the processing steps. What is the batch time

b Construct a Gantt chart of Equipment Use Occupancy Chart.

c Determine the cycle time, and what is the plant capacity in this configuration. Make plausible that the seed and especially main fermenters are the bottleneck.

The plant however operates for about hours per year, processing batches per year or a total annual production of approximately MTyr

d What is cycle time under these conditions and thus how many main fermentors would that require if these operate in a staggered mode

e How many lines of seed fermentors would be required for the number of main fermentors that you found under e If you could not determine the answer of e assume that the answer to e is

The separationpurification section of the process can operate continuously.

fbonus Update the Gantt chart to reflect the increased number of staggered main fermenters and the continuous processing in the separationpurification section.

gbonus What is the role of V Draw the holding volume of V in time for consecutive batches of the main fermenters under eagain use the number if you could not determine the answer of e

Step by Step Solution

There are 3 Steps involved in it

Step: 1

Get Instant Access to Expert-Tailored Solutions

See step-by-step solutions with expert insights and AI powered tools for academic success

Step: 2

Step: 3

Ace Your Homework with AI

Get the answers you need in no time with our AI-driven, step-by-step assistance

Get Started