Question

Question Create a decision tree showing calculation JSW STEEL LTD.: A LOGISTICS DILEMMA On a Sunday morning at 10 oclock, Arun Kumars intercom suddenly came

Question Create a decision tree showing calculation JSW STEEL LTD.: A LOGISTICS DILEMMA

On a Sunday morning at 10 oclock, Arun Kumars intercom suddenly came alive, breaking into his thoughts. It was the last week of September 2014, and the staff at JSW Steel Ltd. (JSW) was frantically focused on last-minute efforts to achieve the companys quarterly targets. Kumar was the senior customer relationship manager to Jindal SAW Ltd. (JSAW), a long-time client of JSW, and he found himself in a difficult spot because he had only a short window of time to decide whether to transport finished materials to JSAW by barge (sea route) or, instead, use the faster but more expensive method of transporting it by rake (rail route).

On a routine day, Kumar would have had no second thoughts on the matter, but today was an exception because JSAW needed the material urgently, and Kumar certainly did not want to shut down his customers production process. The JSW logistics team was putting pressure on Kumar to release the material and send it by rake to JSAW; however, Kumar thought that shipping the materials by barge would still ensure that they reached the client in time, with additional savings for his own company during the crucial quarter-end period. Kumar had less than 12 hours to decide on the mode of transportation and release the material.

THE COMPANY

JSW Steel Ltd. was a steel giant that operated five manufacturing units in India. The company generated annual revenues of 512,196.21 million in 201314 (see Exhibit 1) and was the nations leading private steel manufacturer. JSW produced a variety of steel products, including hot-rolled coils, cold-rolled coils, thermo-mechanically treated sheets, wire rods, galvanized steel, and galvalume sheets. It also manufactured special grades of steel that were used extensively in high-end applications, such as the manufacturing of large-diameter pipes, prefabricated metal structures, and components for auto sectors. The companys largest plantthe Bellary plant in the village of Toranagallu, Karnatakawas strategically located in south India, close to the ports of Goa, Chennai, and Mumbai.

In terms of its corporate vision, JSW aimed to become a globally respected organization through sustainable industrial and business-development practices. The steelmaker had received several awards for its initiatives in cultivating a green philosophy among its employees, processes, and products. One such initiative involved the operation of a responsible supply chain that assessed the benefits to people, planet, and profit throughout its corporate decision-making. Thus, apart from the regular railway routes, the

1 = INR = Indianrupee; all currencyamounts in unless otherwise stated; 1 = US$0.0165 on September 1, 2014.

company made every effort to supply its clients with materials that were shipped by barge to locations that were close to ports (see Exhibit 2). Shipping by barge reduced the time needed to transport material and offered an additional benefit of reducing in the companys carbon footprint.

STEELMAKING AND LOGISTICS

JSW manufactured steel using iron ore, coke,and limestone, either in a blast furnace or in a Corex furnace, which was a more environmentally friendly alternative to the blast furnace. The end products of reduction and melting were hot metal and slag. The hot metal was processed further, by blowing it with oxygen to remove the unwanted carbon. Finer elements, such as vanadium, nickel, cobalt, and titanium, were added to enhance the features of the steel and to make it suitable for specific applications. The steel slabs were rolled through a critical method to manufacture hot-rolled coils, which were then shipped to customers who manufactured pipes and tubes.

The customer put the hot-rolled coils through a flattener and used a special technique called submerged arc welding to manufacture pipes. This process required clean coils to avoid strains on the pipes and tubes produced. The pipes were further processed and used to connect water resources, natural gas, and fuel lines around the world. The timely supply of these hot-rolled coils to the customers was obviously an important concern for JSWs logistics department.

The logistics team used different transportation modes for different locations. The customerin this case, JSAWwas located in the Mundra region of Gujarat, so the closest port was Mundra, and the closest railway siding was Gandhidham. The material for JSAW products had always been transported by rail route from the time the two companies started doing business together; however, with JSWs recent focus on a responsible supply chain, the sea route was also considered as a viable alternative. IndianRailways charged JSW based on a price list that was approved every year, and JSWs accounting department shared this price list with all other departments within the company so they could refer to it to make cost-effective shipping decisions (see Exhibit 3).

The Indian railway system classified its rake services based on the number of rail wagons attached. For example, 45 wagons constituted a BOXN rake and 59 a JUMBO rake. A JUMBO rake could carry 3,500 tons (3,175 tonnes),2 while a BOXN rake could carry 2,500 tons (2,267 tonnes). IndianRailways monopoly gave it the authority to sanction the type of rakes it supplied. The chance of attaining a JUMBO rake on request was just 30 per cent since the railway operated only a small number of JUMBO rakes and availability was limited. Prior to 2014, Kumars experience had taught him that the railway authorities usually gave permission for the requested number of BOXN rakes 80 per cent of the time, and 20 per cent of the time, the allocation was one BOXN rake less than the number requested. Also from experience, Kumar knew that, for a rail shipment, the odds of late arrival were approximately 30 per cent.

South West Port Ltd., Goa, operated the nearest port to Bellary.This port was mostly used for the export of hot-rolled coils, cold-rolled coils, steel plates, and steel sheets to international customers; it was also used for the import of raw materials such as coal and iron ore. Gates 1 to 4 were used for exports, gates 6 and 7 for domestic activity, and gates 8 to 10 for imports. Because South West Port Ltd. was owned by JSW Group, Kumar had always enjoyedthe availability of the requirednumber of rakesbetween the plant and the port.

Most of the barges that entered this port for domestic purposes were carrying coal shipments, and thus, a significant amount of coal and iron dust could damage the surfaces of the coils that were being transported.

2 1 ton = 2,000 pounds or0.907 tonnes.

The vendors who supplied barge transportation that offered clean storage space (Class I) charged a premium (30 per ton) beyond the normal delivery charges, but the availability of such clean-storage barges was only 30 per cent.

Kumar knew that he could place a request with port officials to have Class II vendors provide clean storage space on their barges. In such a case, the vendors would charge an additional 25 per ton, and Kumar estimated only a 75 per cent chance that the cleaning would actually be done. He remembered that Class Ivendors had a record of 80 per cent timely delivery, whereas the Class II vendors had a record of only 35 per cent. The combined cost of transporting coils to the port in Goa by rake and then to the Mudra port by barge was approximately 22 per cent cheaper than that of transporting the coils directlyby rail. JSWs past recordsshowed some variation in activity times acrossboth modes of transportation (see Exhibit 4).

KUMARS PROBLEM

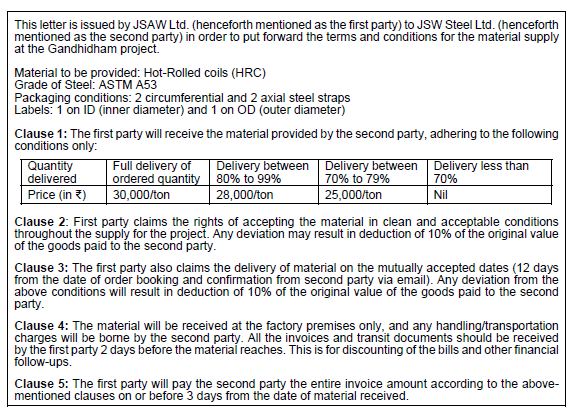

The quantity of steel ordered by JSAW was 7,000 tons (6,350 tonnes), of which 5,000 tons (4,535 tonnes) had already been produced; the remaining 2,500 tons (2,267 tonnes)was under production and was scheduled to be ready for dispatch by 10 p.m. that same day, Sunday. The conditions for delivery of the coils were decided through a memorandum of understanding, and a negotiation document had been drawn up between JSW and JSAW. All terms and conditions were clearly defined for every project(see Exhibit 5).

The intricacies of this logistics problem were growing with every minute that passed, and Kumar knew he needed to make his decision in less than 12 hours. He was under tremendous pressure since this was the last week of the quarter. As well, timely delivery to JSAW was high on Kumars list of priorities, but the logistics department could not confirm the availability of JUMBO or BOXN rakes until the next day, Monday, at 10 a.m.

EXHIBIT 3: EMAIL WITH THE INDIAN RAILWAYS PRICE LIST, 201415

Railway charges (outgoing rakes) are as mentioned below for the year 201415. Under nocircumstances will the prices change unless there is a letter issued by the Railways Board and signedby the manager in-charge, which states explicitly regarding the change.

Table 1: Prices within state and to Goa and Chennai ports (per ton)

DestinationWithin StateGoa and Chennai PortsRest of IndiaPrices1,078

1,193 &1,690

respectively

Follow Table 2

Table 2

Destination (rest of India)Price ()Gurgaon siding3,990Himachal region4,598Mundra region3,180Indore and other partsof Central India2,689Eastern region3,500

Need help with calculations, need to see full calculations of the (Barge) or sea route on decision tree

This letter is issued by JSAW Ltd. (henceforth mentioned as the first party) to JSW Steel Ltd. (henceforth mentioned as the second party) in order to put forward the terms and conditions for the material supply at the Gandhidham project. Material to be provided: Hot-Rolled coils (HRC) Grade of Steel: ASTM A53 Packaging conditions: 2 circumferential and 2 axial steel straps Labels: 1 on ID (inner diameter) and 1 on OD (outer diameter) Clause 1: The first party will receive the material provided by the second party, adhering to the following conditions only: Clause 2: First party claims the rights of accepting the material in clean and acceptable conditions throughout the supply for the project. Any deviation may result in deduction of 10% of the original value of the goods paid to the second party. Clause 3: The first party also claims the delivery of material on the mutually accepted dates (12 days from the date of order booking and confirmation from second party via email). Any deviation from the above conditions will result in deduction of 10% of the original value of the goods paid to the second party. Clause 4: The material will be received at the factory premises only, and any handling/transportation charges will be borne by the second party. All the invoices and transit documents should be received by the first party 2 days before the material reaches. This is for discounting of the bills and other financial follow-ups. Clause 5: The first party will pay the second party the entire invoice amount according to the abovementioned clauses on or before 3 days from the date of material received

Step by Step Solution

There are 3 Steps involved in it

Step: 1

Get Instant Access to Expert-Tailored Solutions

See step-by-step solutions with expert insights and AI powered tools for academic success

Step: 2

Step: 3

Ace Your Homework with AI

Get the answers you need in no time with our AI-driven, step-by-step assistance

Get Started