Answered step by step

Verified Expert Solution

Question

1 Approved Answer

Question No. 1 (13) 160,000 lbm/h propyl alcohol is to be heated from 65F to 100F in a shell-and-tube heat exchanger. The 140,000 lbm/h heated

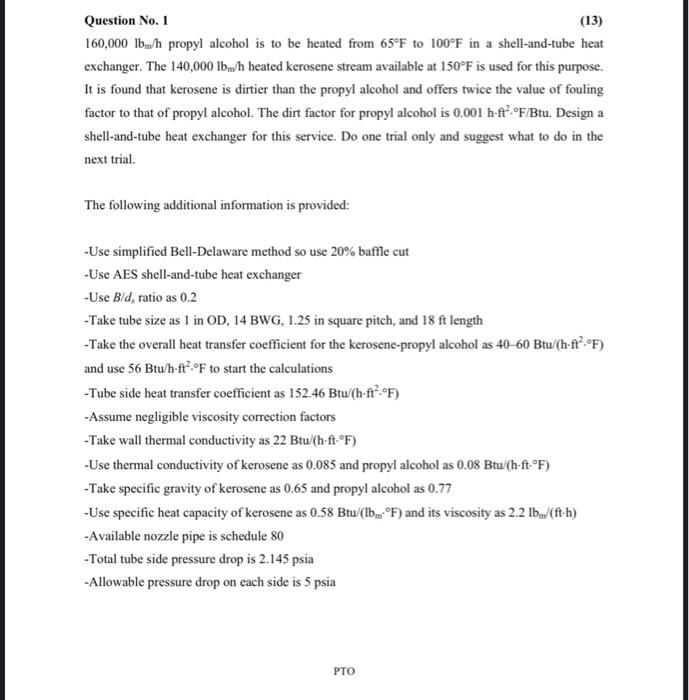

Question No. 1 (13) 160,000 lbm/h propyl alcohol is to be heated from 65F to 100F in a shell-and-tube heat exchanger. The 140,000 lbm/h heated kerosene stream available at 150F is used for this purpose. It is found that kerosene is dirtier than the propyl alcohol and offers twice the value of fouling factor to that of propyl alcohol. The dirt factor for propyl alcohol is 0.001 h.ft.F/Btu. Design a shell-and-tube heat exchanger for this service. Do one trial only and suggest what to do in the next trial. The following additional information is provided: -Use simplified Bell-Delaware method so use 20% baffle cut -Use AES shell-and-tube heat exchanger -Use B/d, ratio as 0.2 -Take tube size as 1 in OD, 14 BWG, 1.25 in square pitch, and 18 ft length -Take the overall heat transfer coefficient for the kerosene-propyl alcohol as 40-60 Btu/(hft.F) and use 56 Btu/h-ft F to start the calculations -Tube side heat transfer coefficient as 152.46 Btu/(h-ft.F) -Assume negligible viscosity correction factors -Take wall thermal conductivity as 22 Btu/(h-ft-F) -Use thermal conductivity of kerosene as 0.085 and propyl alcohol as 0.08 Btu/(h.ft.F) -Take specific gravity of kerosene as 0.65 and propyl alcohol as 0.77 -Use specific heat capacity of kerosene as 0.58 Btu/(lbmF) and its viscosity as 2.2 lbm/(ft-h) -Available nozzle pipe is schedule 80 -Total tube side pressure drop is 2.145 psia -Allowable pressure drop on each side is 5 psia PTO

Step by Step Solution

There are 3 Steps involved in it

Step: 1

Get Instant Access to Expert-Tailored Solutions

See step-by-step solutions with expert insights and AI powered tools for academic success

Step: 2

Step: 3

Ace Your Homework with AI

Get the answers you need in no time with our AI-driven, step-by-step assistance

Get Started