Question stated above- part a-d. Please answer. Thanks

Question stated above- part a-d. Please answer. Thanks

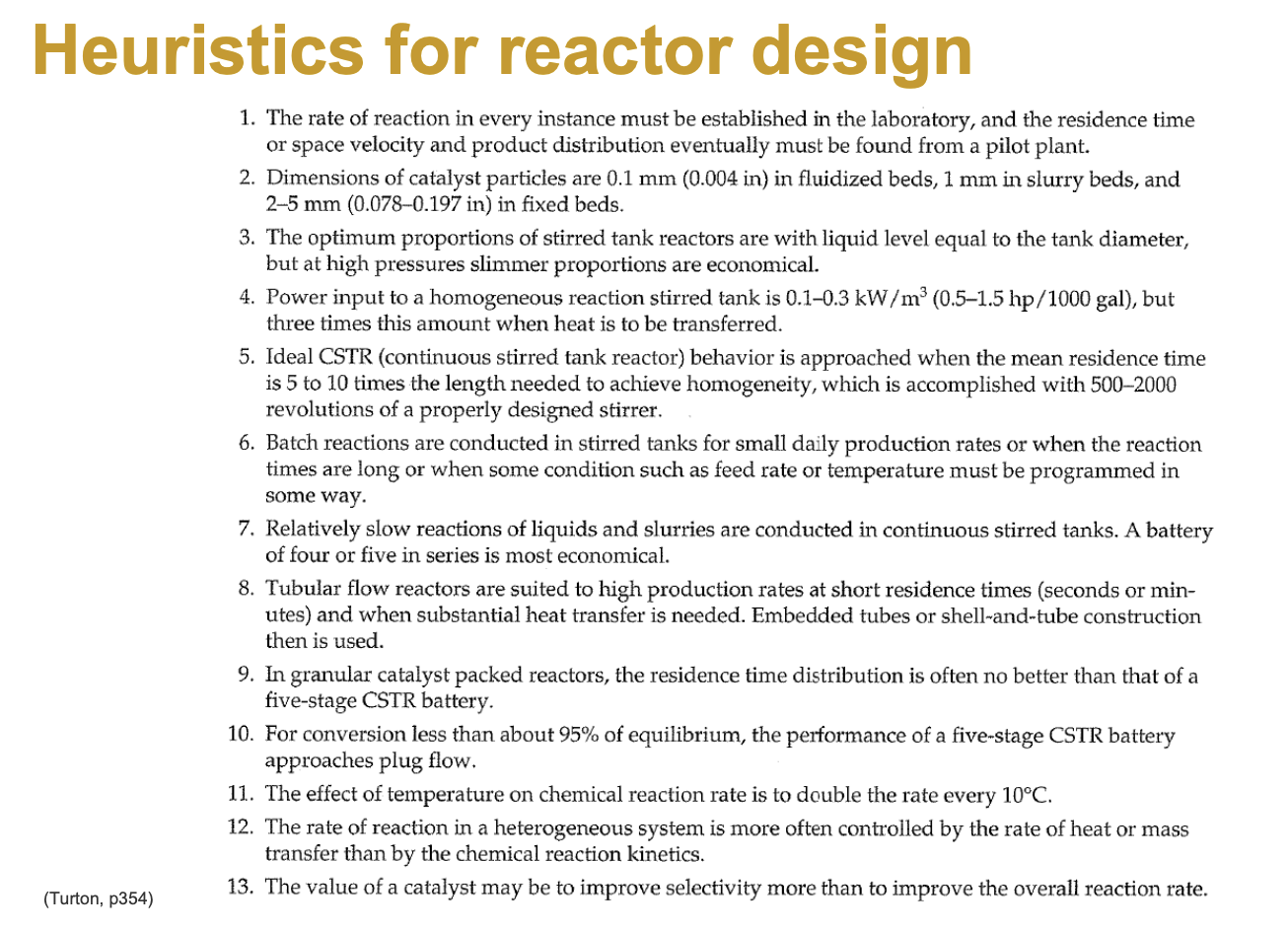

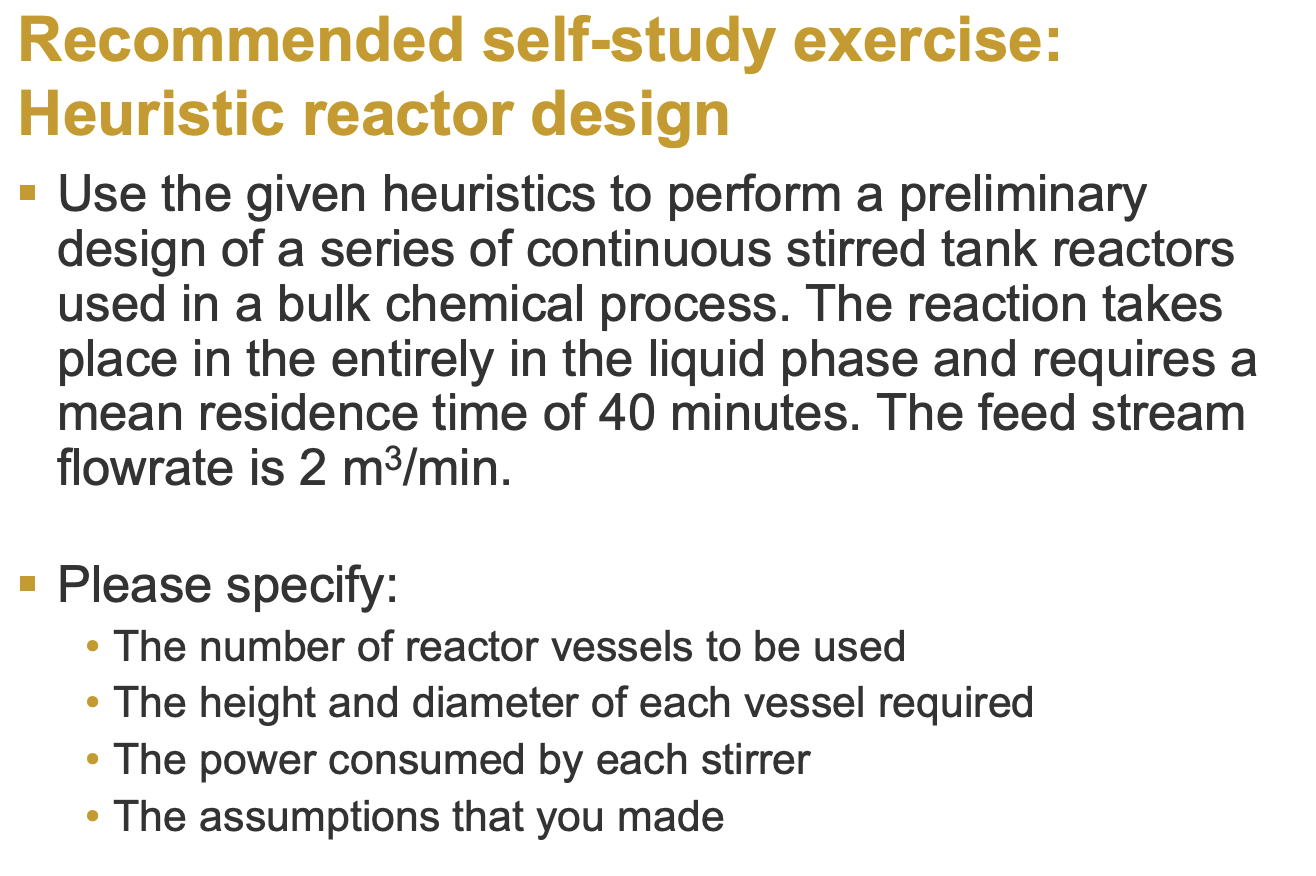

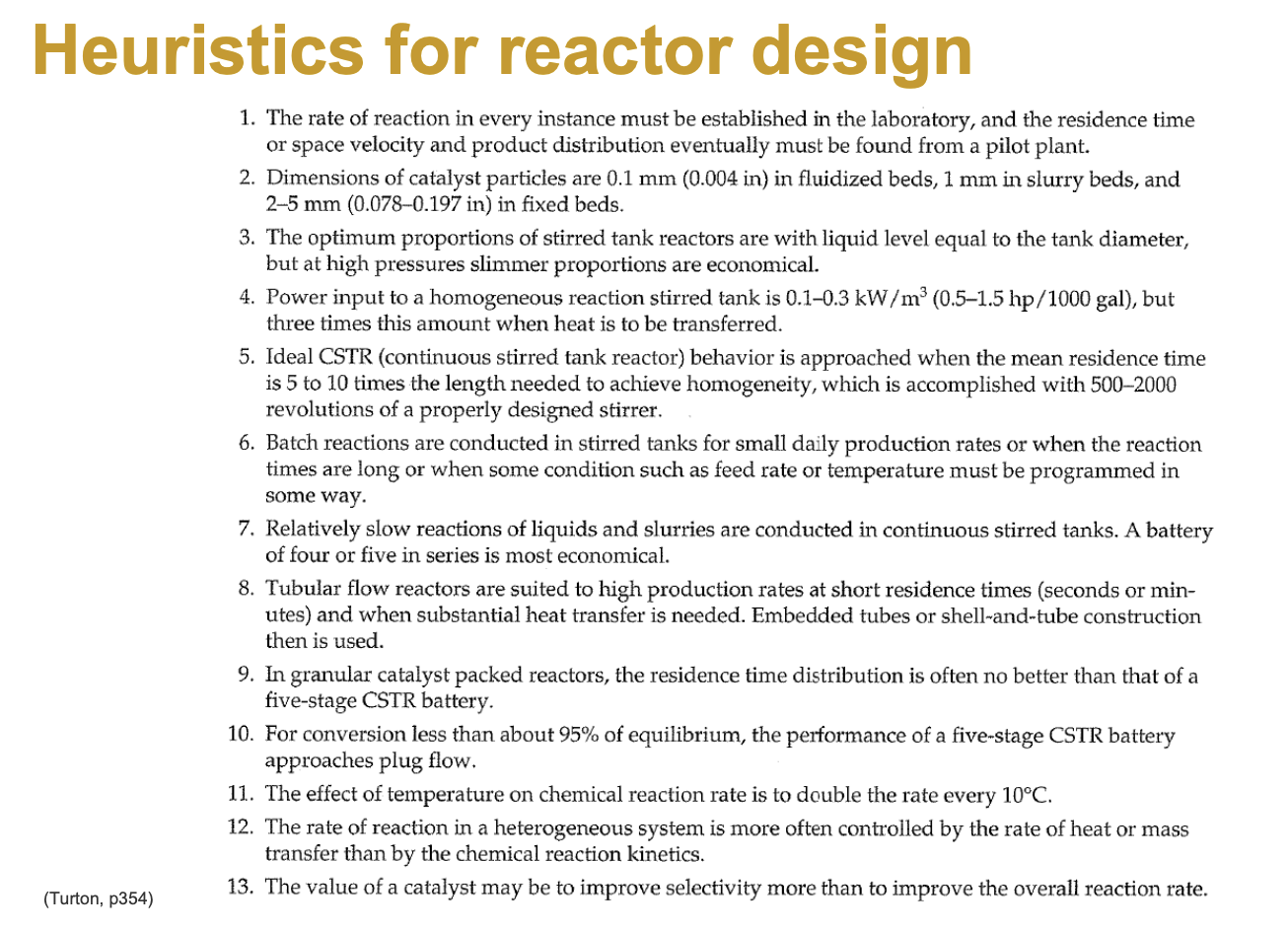

Heuristics for reactor design 1. The rate of reaction in every instance must be established in the laboratory, and the residence time or space velocity and product distribution eventually must be found from a pilot plant. 2. Dimensions of catalyst particles are 0.1mm(0.004in) in fluidized beds, 1mm in slurry beds, and 2-5 mm (0.0780.197in) in fixed beds. 3. The optimum proportions of stirred tank reactors are with liquid level equal to the tank diameter, but at high pressures slimmer proportions are economical. 4. Power input to a homogeneous reaction stirred tank is 0.10.3kW/m3(0.51.5hp/1000gal), but three times this amount when heat is to be transferred. 5. Ideal CSTR (continuous stirred tank reactor) behavior is approached when the mean residence time is 5 to 10 times the length needed to achieve homogeneity, which is accomplished with 500-2000 revolutions of a properly designed stirrer. 6. Batch reactions are conducted in stirred tanks for small daily production rates or when the reaction times are long or when some condition such as feed rate or temperature must be programmed in some way. 7. Relatively slow reactions of liquids and slurries are conducted in continuous stirred tanks. A battery of four or five in series is most economical. 8. Tubular flow reactors are suited to high production rates at short residence times (seconds or minutes) and when substantial heat transfer is needed. Embedded tubes or shell and-tube construction then is used. 9. In granular catalyst packed reactors, the residence time distribution is often no better than that of a five-stage CSTR battery. 10. For conversion less than about 95% of equilibrium, the performance of a five-stage CSTR battery approaches plug flow. 11. The effect of temperature on chemical reaction rate is to double the rate every 10C. 12. The rate of reaction in a heterogeneous system is more often controlled by the rate of heat or mass transfer than by the chemical reaction kinetics. Recommended self-study exercise: Heuristic reactor design - Use the given heuristics to perform a preliminary design of a series of continuous stirred tank reactors used in a bulk chemical process. The reaction takes place in the entirely in the liquid phase and requires a mean residence time of 40 minutes. The feed stream flowrate is 2m3/min. - Please specify: - The number of reactor vessels to be used - The height and diameter of each vessel required - The power consumed by each stirrer - The assumptions that you made Heuristics for reactor design 1. The rate of reaction in every instance must be established in the laboratory, and the residence time or space velocity and product distribution eventually must be found from a pilot plant. 2. Dimensions of catalyst particles are 0.1mm(0.004in) in fluidized beds, 1mm in slurry beds, and 2-5 mm (0.0780.197in) in fixed beds. 3. The optimum proportions of stirred tank reactors are with liquid level equal to the tank diameter, but at high pressures slimmer proportions are economical. 4. Power input to a homogeneous reaction stirred tank is 0.10.3kW/m3(0.51.5hp/1000gal), but three times this amount when heat is to be transferred. 5. Ideal CSTR (continuous stirred tank reactor) behavior is approached when the mean residence time is 5 to 10 times the length needed to achieve homogeneity, which is accomplished with 500-2000 revolutions of a properly designed stirrer. 6. Batch reactions are conducted in stirred tanks for small daily production rates or when the reaction times are long or when some condition such as feed rate or temperature must be programmed in some way. 7. Relatively slow reactions of liquids and slurries are conducted in continuous stirred tanks. A battery of four or five in series is most economical. 8. Tubular flow reactors are suited to high production rates at short residence times (seconds or minutes) and when substantial heat transfer is needed. Embedded tubes or shell and-tube construction then is used. 9. In granular catalyst packed reactors, the residence time distribution is often no better than that of a five-stage CSTR battery. 10. For conversion less than about 95% of equilibrium, the performance of a five-stage CSTR battery approaches plug flow. 11. The effect of temperature on chemical reaction rate is to double the rate every 10C. 12. The rate of reaction in a heterogeneous system is more often controlled by the rate of heat or mass transfer than by the chemical reaction kinetics. Recommended self-study exercise: Heuristic reactor design - Use the given heuristics to perform a preliminary design of a series of continuous stirred tank reactors used in a bulk chemical process. The reaction takes place in the entirely in the liquid phase and requires a mean residence time of 40 minutes. The feed stream flowrate is 2m3/min. - Please specify: - The number of reactor vessels to be used - The height and diameter of each vessel required - The power consumed by each stirrer - The assumptions that you made

Question stated above- part a-d. Please answer. Thanks

Question stated above- part a-d. Please answer. Thanks