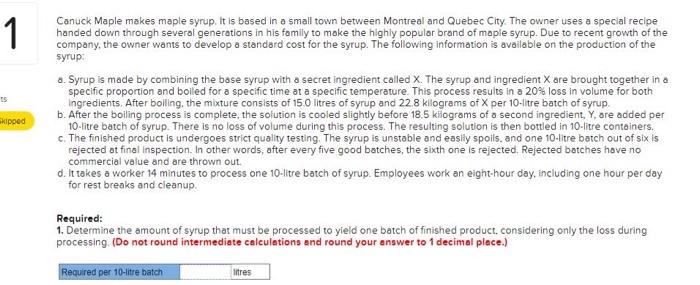

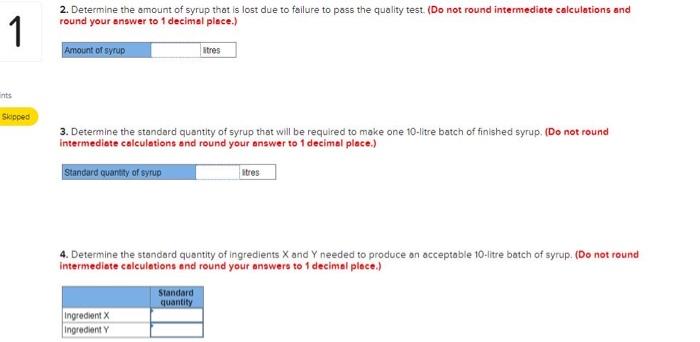

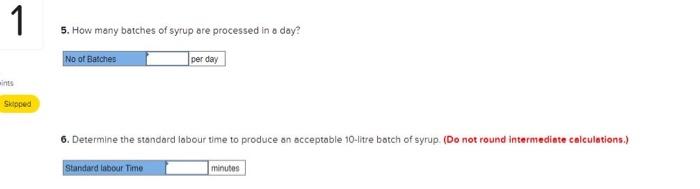

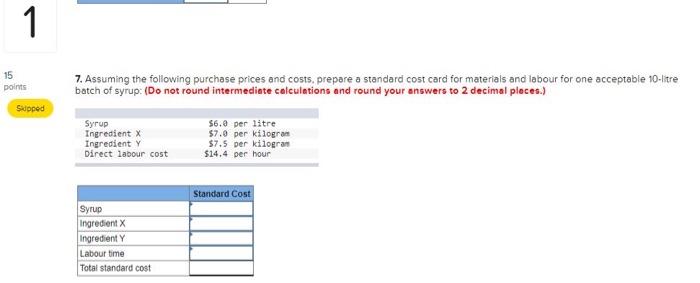

Canuck Maple makes maple syrup. It is based in a small town between Montreal and Quebec City. The owner uses a special recipe handed down through several generations in his family to make the highly popular brand of maple syrup. Due to recent growth of the company, the owner wants to develop a standard cost for the syrup. The following information is available on the production of the syrup: a. Syrup is made by combining the base syrup with a secret ingredient called X. The syrup and ingredient X are brought together in a specific proportion and boiled for a specific time at a specific temperature. This process results in a 20% loss in volume for both Ingredients. After bolling. the mixture consists of 15.0 litres of syrup and 22.8klllograms of X per 10 -litre batch of syrup. b. After the boiling process is complete, the solution is cooled slightly before 18.5kllograms of a second ingredient, Y, are added per 10 -litre batch of syrup. There is no loss of volume during this process. The resulting solution is then bottled in 10 -litre containers. c. The finished product is undergoes strict quality testing. The syrup is unstable and easlly spoils. and one 10 -litre batch out of six is rejected at final inspection. In other words, after every five good batches, the sixth one is rejected. Rejected batches hove no commercial value and are thrown out. d. It takes a worker 14 minutes to process one 10-litre batch of syrup. Employees work an eight-hour day, including one hour per day for rest breaks and cleanup. Required: 1. Determine the amount of syrup that must be processed to yield one batch of finished product, considering only the loss during processing. (Do not round intermediate calculations and round your answer to 1 decimal place.) 2. Determine the amount of syrup that is lost due to failure to poss the quality test. (Do not round intermediote calculations and round your answer to 1 decimal plece.) 3. Determine the standard quantity of syrup that will be required to make one 10-litre batch of finished syrup. (Do not round intermediate calculations and round your answer to 1 decimal place.) 4. Determine the standard quantity of ingredients X and Y needed to produce an acceptable 10-litre batch of syrup. (Do not round intermediate calculations and round your answers to 1 decimel plece.) 5. How many batches of syrup are processed in o day? 6. Determine the standard labour time to produce an acceptable 10-litre botch of syrup. (Do not round intermediate calculations.) 7. Assuming the following purchase prices and costs, prepare a standard cost card for materials and labour for one acceptable 10 -litre batch of syrup: (Do not round intermediate calculations and round your answers to 2 decimal pleces.) Canuck Maple makes maple syrup. It is based in a small town between Montreal and Quebec City. The owner uses a special recipe handed down through several generations in his family to make the highly popular brand of maple syrup. Due to recent growth of the company, the owner wants to develop a standard cost for the syrup. The following information is available on the production of the syrup: a. Syrup is made by combining the base syrup with a secret ingredient called X. The syrup and ingredient X are brought together in a specific proportion and boiled for a specific time at a specific temperature. This process results in a 20% loss in volume for both Ingredients. After bolling. the mixture consists of 15.0 litres of syrup and 22.8klllograms of X per 10 -litre batch of syrup. b. After the boiling process is complete, the solution is cooled slightly before 18.5kllograms of a second ingredient, Y, are added per 10 -litre batch of syrup. There is no loss of volume during this process. The resulting solution is then bottled in 10 -litre containers. c. The finished product is undergoes strict quality testing. The syrup is unstable and easlly spoils. and one 10 -litre batch out of six is rejected at final inspection. In other words, after every five good batches, the sixth one is rejected. Rejected batches hove no commercial value and are thrown out. d. It takes a worker 14 minutes to process one 10-litre batch of syrup. Employees work an eight-hour day, including one hour per day for rest breaks and cleanup. Required: 1. Determine the amount of syrup that must be processed to yield one batch of finished product, considering only the loss during processing. (Do not round intermediate calculations and round your answer to 1 decimal place.) 2. Determine the amount of syrup that is lost due to failure to poss the quality test. (Do not round intermediote calculations and round your answer to 1 decimal plece.) 3. Determine the standard quantity of syrup that will be required to make one 10-litre batch of finished syrup. (Do not round intermediate calculations and round your answer to 1 decimal place.) 4. Determine the standard quantity of ingredients X and Y needed to produce an acceptable 10-litre batch of syrup. (Do not round intermediate calculations and round your answers to 1 decimel plece.) 5. How many batches of syrup are processed in o day? 6. Determine the standard labour time to produce an acceptable 10-litre botch of syrup. (Do not round intermediate calculations.) 7. Assuming the following purchase prices and costs, prepare a standard cost card for materials and labour for one acceptable 10 -litre batch of syrup: (Do not round intermediate calculations and round your answers to 2 decimal pleces.)