Question

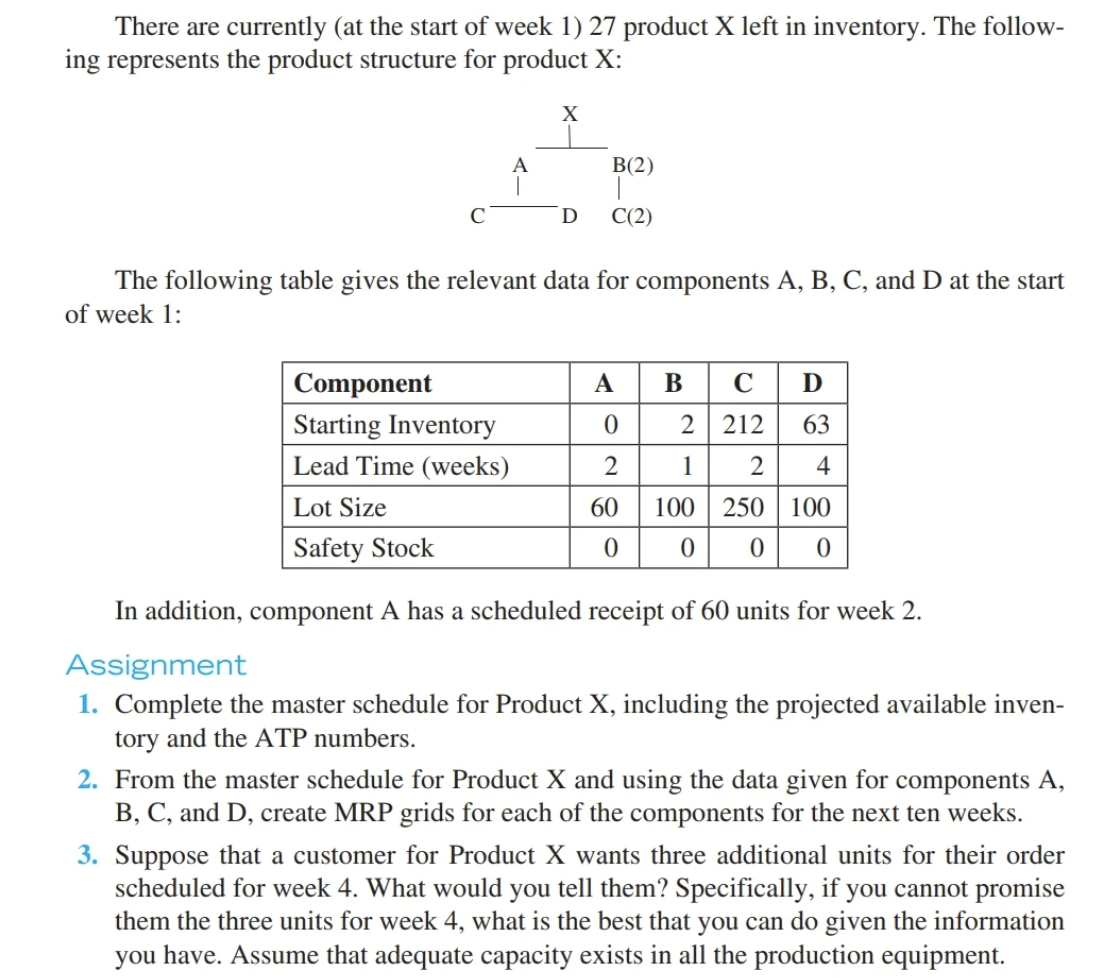

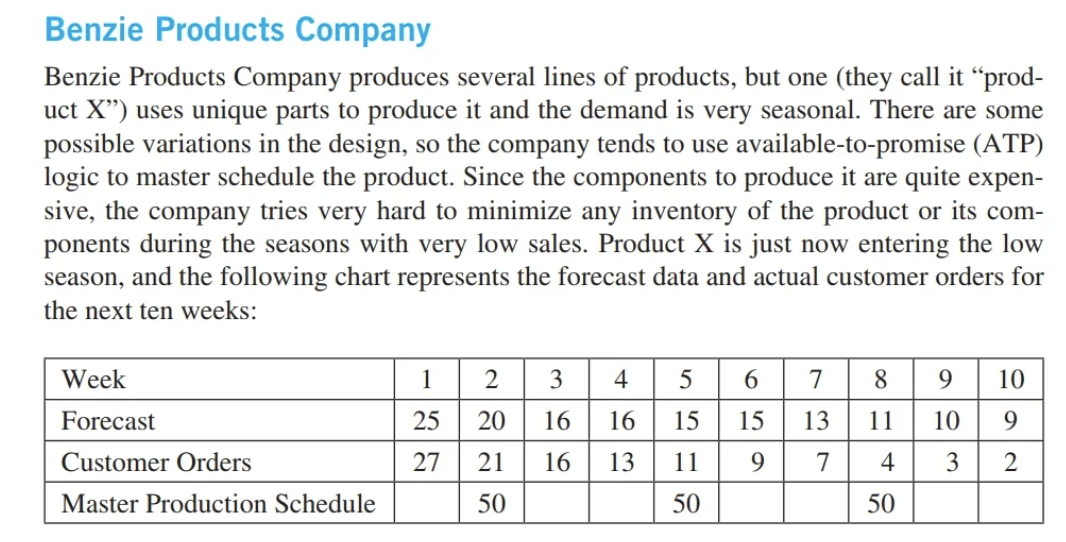

Read the case up through the BOM for product X. Then, use the following information ( and not the remaining information in the case )

Read the case up through the BOM for product X. Then, use the following information (and not the remaining information in the case) to complete the case analysis:

The partial MPS given in the case has an error. Correct the error as you solve the MPS.

Lead time for product X is 1 week.

Relevant data for components A, B, C and D at the start of week 1:

| Component | A | B | C | D |

| Starting Inventory | 0 | 112 | 212 | 98 |

| Lead time (weeks) | 2 | 1 | 1 | 3 |

| Lot Size | FOQ = 60 | POQ w/P=4 wks | LFL | FOQ = 100 |

| Safety Stock | 0 | 10 | 20 | 0 |

| Scrap factor |

|

| 10% |

|

In addition, item D has independent demand of 5 units/week. Also, item A has a scheduled receipt of 60 units for week 1.

In the Assignments section, answer items 1, 2 and 3

Step by Step Solution

There are 3 Steps involved in it

Step: 1

Get Instant Access to Expert-Tailored Solutions

See step-by-step solutions with expert insights and AI powered tools for academic success

Step: 2

Step: 3

Ace Your Homework with AI

Get the answers you need in no time with our AI-driven, step-by-step assistance

Get Started