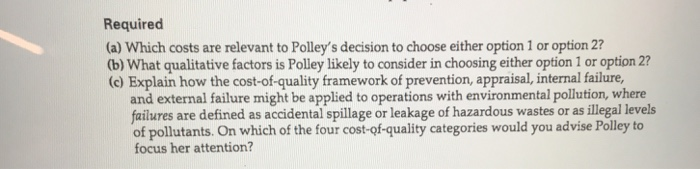

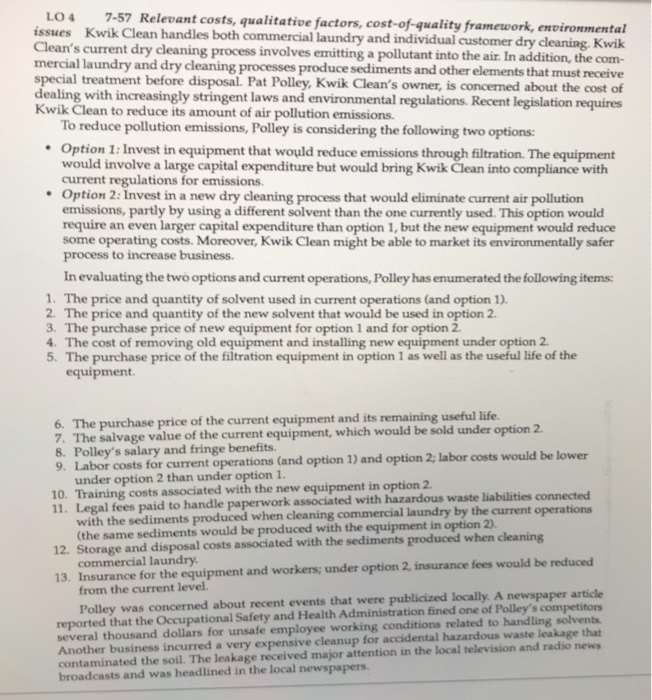

Required (a) Which costs are relevant to Polley's decision to choose either option 1 or option 2? (b) What qualitative factors is Polley likely to consider in choosing either option 1 or option 2? (c) Explain how the cost-of-quality framework of prevention, appraisal, internal failure and external failure might be applied to operations with environmental pollution, where failures are defined as accidental spillage or leakage of hazardous wastes or as illegal levels of pollutants. On which of the four cost-of-quality categories would you advise Polley to focus her attention? LO4 7-57 Relevant costs, qualitative factors, cost-of-quality framework, environmental issues Kwik Clean handles both co Clean's current dry cleaning process involves emitting a pollutant into the air. In addition, the com- mercial laundry and dry cleaning processes produce sediments and other elements that must receive special treatment before disposal. Pat Polley, Kwik Clean's owner, is concerned about the cost of dealing with increasingly stringent laws and environmental regulations. Recent legislation requires Kwik Clean to reduce its amount of air pollution emissions. mmercial laundry and individual customer dry cleaning. Kwik To reduce pollution emissions, Polley is considering the following two options: Option 1: Invest in equipment that would reduce emissions through filtration. The equipment would involve a large capital expenditure but would bring Kwik Clean into compliance with current regulations for emissions. Option 2: Invest in a new dry cleaning process that would eliminate current air pollution emissions, partly by using a different solvent than the one currently used. This option woukd require an even larger capital expenditure than option 1, but the new equipment would reduce some operating costs. Moreover, Kwik Clean might be able to market its environmentally safer rocess to increase business In evaluating the two options and current operations, Polley has enumerated the following items: 1. The price and quantity of solvent used in current operations (and option 1) 2. The price and quantity of the new solvent that would be used in option 2. 3. The purchase price of new equipment for option 1 and for option 2 4. The cost of removing old equipment and installing new equipment under option 2 5. The purchase price of the filtration equipment in option 1 as well as the usefal life of th equipment 6. The purchase price of the current equipment and its remaining useful life The salvage value of the current equipment, which would be sold under option 2 9. Labor costs for current operations (and option 1) and option 2, labor costs would be lower under option 2 than under option 1 10. Training costs associated with the new equipment in option 2 11. Legal fees paid to handle paperwork associated with hazardous waste liabilities connected with the sediments produced when cleaning commercial laundry by the current operations (the same sediments would be produced with the equipment in option 2) 12. Storage and disposal costs associated with the sediments produced when cleaning commercial laundry 13. Insurance for the equipment and workers; under option 2, insurance fees would be reduced from the current level. Polley was concerned about recent events that were publicized locally. A newspaper article reported that the Occupational Safety and Health Administration fined one of Polley's competitors several thousand dollars for unsafe employee working conditions related to handling solvents Another business incurred a very expensive cleanup for accidental hazardous waste leakage that contaminated the soil. The leakage received major attention in the local television and radio news broadcasts and was head lined in the local newspapers