Answered step by step

Verified Expert Solution

Question

1 Approved Answer

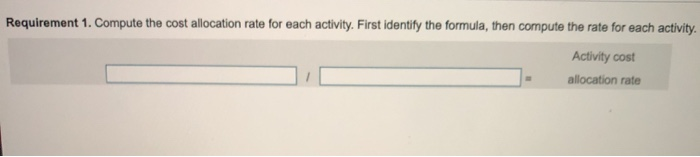

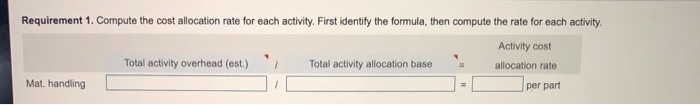

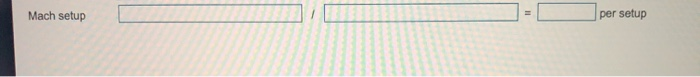

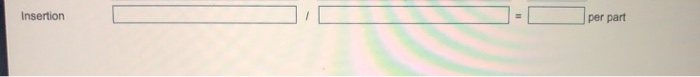

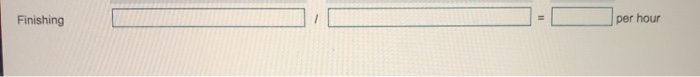

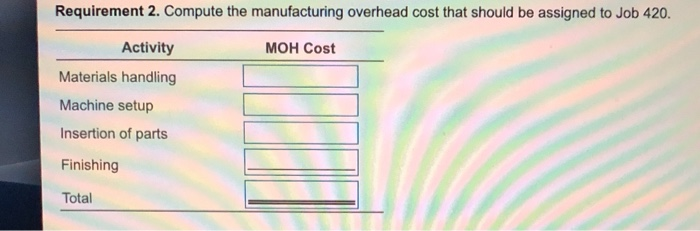

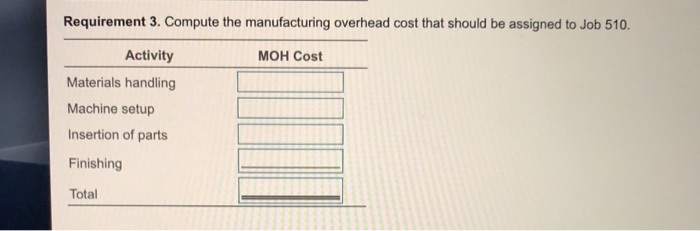

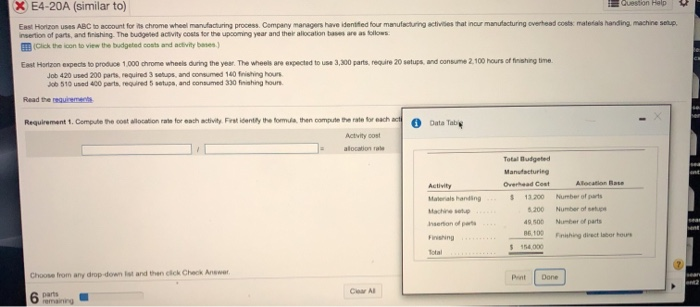

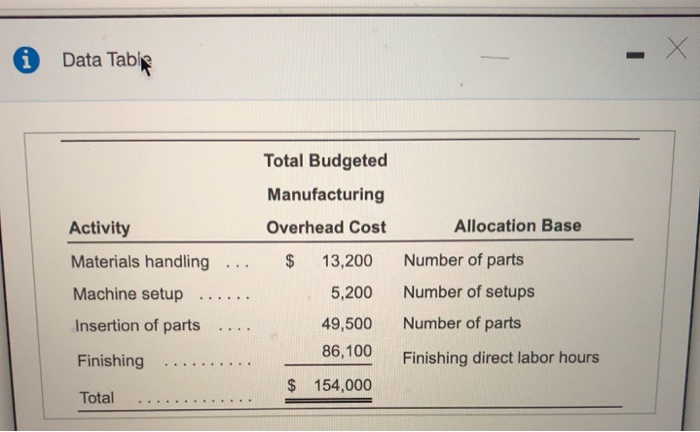

Requirement 1. Compute the cost allocation rate for each activity. First identify the formula, then compute the rate for each activity Activity cost allocation rate

Step by Step Solution

There are 3 Steps involved in it

Step: 1

Get Instant Access to Expert-Tailored Solutions

See step-by-step solutions with expert insights and AI powered tools for academic success

Step: 2

Step: 3

Ace Your Homework with AI

Get the answers you need in no time with our AI-driven, step-by-step assistance

Get Started