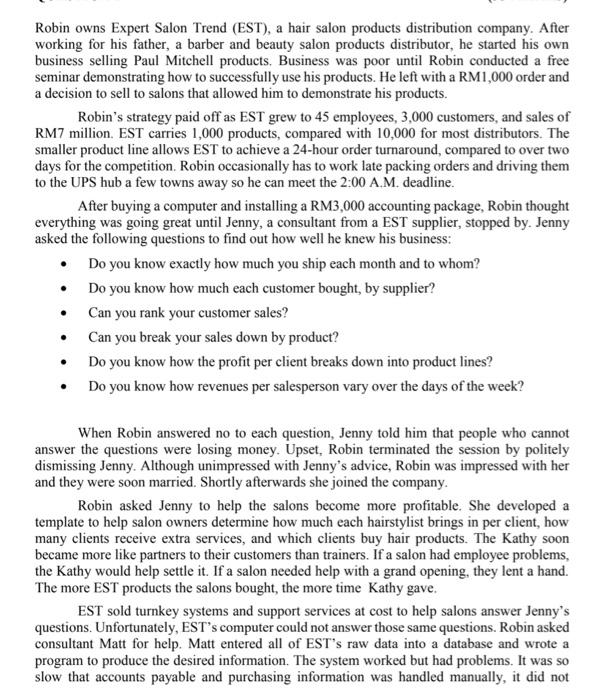

Robin owns Expert Salon Trend (EST), a hair salon products distribution company. After working for his father, a barber and beauty salon products distributor, he started his own business selling Paul Mitchell products, Business was poor until Robin conducted a free seminar demonstrating how to successfully use his products. He left with a RM1,000 order and a decision to sell to salons that allowed him to demonstrate his products. Robin's strategy paid off as EST grew to 45 employees, 3,000 customers, and sales of RM7 million. EST carries 1,000 products, compared with 10,000 for most distributors. The smaller product line allows EST to achieve a 24-hour order turnaround, compared to over two days for the competition. Robin occasionally has to work late packing orders and driving them to the UPS hub a few towns away so he can meet the 2:00 A.M. deadline. After buying a computer and installing a RM3,000 accounting package, Robin thought everything was going great until Jenny, a consultant from a EST supplier, stopped by. Jenny asked the following questions to find out how well he knew his business: Do you know exactly how much you ship each month and to whom? Do you know how much each customer bought, by supplier? Can you rank your customer sales? Can you break your sales down by product? Do you know how the profit per client breaks down into product lines? Do you know how revenues per salesperson vary over the days of the week? When Robin answered no to each question, Jenny told him that people who cannot answer the questions were losing money. Upset, Robin terminated the session by politely dismissing Jenny. Although unimpressed with Jenny's advice, Robin was impressed with her and they were soon married. Shortly afterwards she joined the company. Robin asked Jenny to help the salons become more profitable. She developed a template to help salon owners determine how much each hairstylist brings in per client, how many clients receive extra services, and which clients buy hair products. The Kathy soon became more like partners to their customers than trainers. If a salon had employee problems, the Kathy would help settle it. If a salon needed help with a grand opening, they lent a hand. The more EST products the salons bought, the more time Kathy gave. EST sold turnkey systems and support services at cost to help salons answer Jenny's questions. Unfortunately, EST's computer could not answer those same questions. Robin asked consultant Matt for help. Matt entered all of EST's raw data into a database and wrote a program to produce the desired information. The system worked but had problems. It was so slow that accounts payable and purchasing information was handled manually, it did not answer Jenny's growing list of questions, and only a few months of detailed information were available at a time. To alleviate these problems, Robin hired Matt as the company controller After reading an industry report, Robin realized it was time to purchase a new system Robin and Matt decided to evaluate and select the software themselves and rely on the vendor for installation help. They spent months researching software and attending demonstrations before settling on a RM20,000 system. The vendor began installing the system and training EST personnel Three days prior to conversion, Robin met a distributor who described how his system met his detailed accounting and customer reporting needs as well as his inventory management and order fulfillment needs. Robin was so impressed that they stopped the conversion, went to Bangkok to check out the distributor's system, and flew to Manila to visit Wrasse System Management (WSM), the software developer. WSM did a great job of demonstrating the software and provided Robin and Matt with great references. The only hitch was WSM's inability to demonstrate two features that were particularly important: adjusting orders automatically to reflect outstanding customer credits and back orders, and determining the least expensive way to pack and ship each order. WSM's salespeople assured them that those features would be up and running by the time the package was delivered to EST Their economic feasibility analysis showed RM234,000 in yearly savings. RM 144,000 Most EST orders consist of several boxes, 95% of which are sent cash on delivery (COD). The old EST system had no way to prepare orders for multiple-box shipments, a five-box order required five sales invoices and five COD tickets. The new system allowed EST to generate one sales order and ship one box COD and the other four by regular delivery. Not having to ship every box COD would save RM144,000 a year. RM50,000 EST paid a Certified Public Accountant firm RM50,000 a year to prepare its financial statements. The new software would prepare the statements automatically RM40,000 Because the old system did not have credit-managing capabilities, it was hard to detect past-due accounts. Earlier detection of past-due accounts would result in faster collections, fewer lost customers, and fewer write-offs. Unknown The major reason for acquiring the system was to improve customer service by making more detailed customer information available. After estimated annual maintenance costs of RM10,000, there was an annual return on investment of RM224,000. Because the system would pay for itself in less than a year, Robin bought it and wrote off his RM20,000 investments in the other system When WSM installed the software, Robin found out that the promised features were not available and that there was no immediate plan to add them. Although Robin and Matt were upset, they had to shoulder some of the blame for not insisting on the two features before signing the deal. They found a program that automatically determined the cheapest way to pack and ship an order. WSM agreed to pay half of the RM10,000 cost to integrate it into the program, WSM offered to create the module to reflect customer credits and back orders for another RM20,000, but Robin declined. These problems pushed the conversion date back several months. EST spent three months preparing to implement the new system. Training EST employees to use the new system was particularly important. Adding a customer to the database required only one screen with the old system, the new software required six screens. Employees were taught to shout "Fire!" when they had a problem they could not handle. Matt or a WSM programmer explained the error and how to correct it. During implementation, the new system was tested for glitches by processing real data. Looking back, Matt admits three months were not nearly enough for the training and testing. They should have used twice as much time to identify and eliminate glitches. When EST converted to the new system, telephone operators were confronted with situations they had not been trained to handle. Soon everyone was yelling "Fire!" at the same time. In less than one hour, so many operators were waiting for help that the programmers stopped explaining the correct procedures and simply ran from operator to operator correcting problems. Mistakes were repeated numerous times, and the situation intensified. Some employees, frustrated by their inability to work the new system, broke down and cried openly. In the warehouse, Robin was not having much fun either. On a normal day, EST has 200 to 300 boxes ready for 3:30 P.M. shipment. On conversion day, a lone box sat ready to go. Facing the first default on his 24-hour turnaround promise, Robin, Jenny, Matt, and a few others stayed past midnight packing and loading boxes on trucks. They barely made it to the UPS hub on time. The next day, order entry and shipping proceeded more smoothly, but Robin could not retrieve data to monitor sales. That did not make him feel too kindly about his RM200,000 system or WSM. It took Robin weeks to figure out how to get data to monitor sales. When he did, he was horrified that sales had dropped 15%. They had focused so hard on getting the system up and running that they took their eyes off the customers. To make matters worse, Robin could not get information on sales by customer, salesperson, or product, nor could he figure out why or where sales were falling Things quickly improved after "Hell Week. Orders were entered just as quickly, and warehouse operations improved thanks to the integrated add-in program. The new system provided pickers with the most efficient path to follow and told them which items to pack in which boxes based on destination and weight. The system selected a carrier and printed labels for the boxes. Order turnaround time was shaved to 20 minutes from five hours. Months after the system was installed, it still did not do everything Robin needed, including some things the old system did. Nor did it answer all of Jenny's questions. Robin is confident, however, that the system will eventually provide EST with a distinct competitive advantage. He is negotiating with WSM to write the credit and back-order module. Robin believes the step up to the new system was the right move for his growing company. With the exceptions of taking the WSM salesperson's word and not taking enough time to practice with the system, Robin feels EST did as good a job as it could have in selecting, installing, and implementing a new system. Required: (a) Do you agree that EST did a good job selecting, installing, and implementing the new system? Explain. (3 marks) (CLOI:PLOI:C4) (b) Do you feel EST could have done a better job? If so, what did it do wrong, and what should it have done differently? Justify. (9 marks) (CLOI:PLOI:C4) (C) (d) (e) Describes how could EST have avoided the missing features problem in the new system. (3 marks) (CLOI:PLOI:C4) Suggest how could EST can avoided conversion and reporting problems in new system. (6 marks) (CLOI:PLOI:C4) Evaluate Robin's economic feasibility analysis. Do you agree with his numbers and his conclusions? (5 marks) (CLOI:PLOI:C4) Examine how could EST's customers use the new multi-box shipping approach to defraud EST (3 marks) (CLOI:PLOI:C5) Assess how would you rate the service EST received from WSM in term of good and bad. (6 marks) (CLOI:PLOI:C5) (f) Robin owns Expert Salon Trend (EST), a hair salon products distribution company. After working for his father, a barber and beauty salon products distributor, he started his own business selling Paul Mitchell products, Business was poor until Robin conducted a free seminar demonstrating how to successfully use his products. He left with a RM1,000 order and a decision to sell to salons that allowed him to demonstrate his products. Robin's strategy paid off as EST grew to 45 employees, 3,000 customers, and sales of RM7 million. EST carries 1,000 products, compared with 10,000 for most distributors. The smaller product line allows EST to achieve a 24-hour order turnaround, compared to over two days for the competition. Robin occasionally has to work late packing orders and driving them to the UPS hub a few towns away so he can meet the 2:00 A.M. deadline. After buying a computer and installing a RM3,000 accounting package, Robin thought everything was going great until Jenny, a consultant from a EST supplier, stopped by. Jenny asked the following questions to find out how well he knew his business: Do you know exactly how much you ship each month and to whom? Do you know how much each customer bought, by supplier? Can you rank your customer sales? Can you break your sales down by product? Do you know how the profit per client breaks down into product lines? Do you know how revenues per salesperson vary over the days of the week? When Robin answered no to each question, Jenny told him that people who cannot answer the questions were losing money. Upset, Robin terminated the session by politely dismissing Jenny. Although unimpressed with Jenny's advice, Robin was impressed with her and they were soon married. Shortly afterwards she joined the company. Robin asked Jenny to help the salons become more profitable. She developed a template to help salon owners determine how much each hairstylist brings in per client, how many clients receive extra services, and which clients buy hair products. The Kathy soon became more like partners to their customers than trainers. If a salon had employee problems, the Kathy would help settle it. If a salon needed help with a grand opening, they lent a hand. The more EST products the salons bought, the more time Kathy gave. EST sold turnkey systems and support services at cost to help salons answer Jenny's questions. Unfortunately, EST's computer could not answer those same questions. Robin asked consultant Matt for help. Matt entered all of EST's raw data into a database and wrote a program to produce the desired information. The system worked but had problems. It was so slow that accounts payable and purchasing information was handled manually, it did not answer Jenny's growing list of questions, and only a few months of detailed information were available at a time. To alleviate these problems, Robin hired Matt as the company controller After reading an industry report, Robin realized it was time to purchase a new system Robin and Matt decided to evaluate and select the software themselves and rely on the vendor for installation help. They spent months researching software and attending demonstrations before settling on a RM20,000 system. The vendor began installing the system and training EST personnel Three days prior to conversion, Robin met a distributor who described how his system met his detailed accounting and customer reporting needs as well as his inventory management and order fulfillment needs. Robin was so impressed that they stopped the conversion, went to Bangkok to check out the distributor's system, and flew to Manila to visit Wrasse System Management (WSM), the software developer. WSM did a great job of demonstrating the software and provided Robin and Matt with great references. The only hitch was WSM's inability to demonstrate two features that were particularly important: adjusting orders automatically to reflect outstanding customer credits and back orders, and determining the least expensive way to pack and ship each order. WSM's salespeople assured them that those features would be up and running by the time the package was delivered to EST Their economic feasibility analysis showed RM234,000 in yearly savings. RM 144,000 Most EST orders consist of several boxes, 95% of which are sent cash on delivery (COD). The old EST system had no way to prepare orders for multiple-box shipments, a five-box order required five sales invoices and five COD tickets. The new system allowed EST to generate one sales order and ship one box COD and the other four by regular delivery. Not having to ship every box COD would save RM144,000 a year. RM50,000 EST paid a Certified Public Accountant firm RM50,000 a year to prepare its financial statements. The new software would prepare the statements automatically RM40,000 Because the old system did not have credit-managing capabilities, it was hard to detect past-due accounts. Earlier detection of past-due accounts would result in faster collections, fewer lost customers, and fewer write-offs. Unknown The major reason for acquiring the system was to improve customer service by making more detailed customer information available. After estimated annual maintenance costs of RM10,000, there was an annual return on investment of RM224,000. Because the system would pay for itself in less than a year, Robin bought it and wrote off his RM20,000 investments in the other system When WSM installed the software, Robin found out that the promised features were not available and that there was no immediate plan to add them. Although Robin and Matt were upset, they had to shoulder some of the blame for not insisting on the two features before signing the deal. They found a program that automatically determined the cheapest way to pack and ship an order. WSM agreed to pay half of the RM10,000 cost to integrate it into the program, WSM offered to create the module to reflect customer credits and back orders for another RM20,000, but Robin declined. These problems pushed the conversion date back several months. EST spent three months preparing to implement the new system. Training EST employees to use the new system was particularly important. Adding a customer to the database required only one screen with the old system, the new software required six screens. Employees were taught to shout "Fire!" when they had a problem they could not handle. Matt or a WSM programmer explained the error and how to correct it. During implementation, the new system was tested for glitches by processing real data. Looking back, Matt admits three months were not nearly enough for the training and testing. They should have used twice as much time to identify and eliminate glitches. When EST converted to the new system, telephone operators were confronted with situations they had not been trained to handle. Soon everyone was yelling "Fire!" at the same time. In less than one hour, so many operators were waiting for help that the programmers stopped explaining the correct procedures and simply ran from operator to operator correcting problems. Mistakes were repeated numerous times, and the situation intensified. Some employees, frustrated by their inability to work the new system, broke down and cried openly. In the warehouse, Robin was not having much fun either. On a normal day, EST has 200 to 300 boxes ready for 3:30 P.M. shipment. On conversion day, a lone box sat ready to go. Facing the first default on his 24-hour turnaround promise, Robin, Jenny, Matt, and a few others stayed past midnight packing and loading boxes on trucks. They barely made it to the UPS hub on time. The next day, order entry and shipping proceeded more smoothly, but Robin could not retrieve data to monitor sales. That did not make him feel too kindly about his RM200,000 system or WSM. It took Robin weeks to figure out how to get data to monitor sales. When he did, he was horrified that sales had dropped 15%. They had focused so hard on getting the system up and running that they took their eyes off the customers. To make matters worse, Robin could not get information on sales by customer, salesperson, or product, nor could he figure out why or where sales were falling Things quickly improved after "Hell Week. Orders were entered just as quickly, and warehouse operations improved thanks to the integrated add-in program. The new system provided pickers with the most efficient path to follow and told them which items to pack in which boxes based on destination and weight. The system selected a carrier and printed labels for the boxes. Order turnaround time was shaved to 20 minutes from five hours. Months after the system was installed, it still did not do everything Robin needed, including some things the old system did. Nor did it answer all of Jenny's questions. Robin is confident, however, that the system will eventually provide EST with a distinct competitive advantage. He is negotiating with WSM to write the credit and back-order module. Robin believes the step up to the new system was the right move for his growing company. With the exceptions of taking the WSM salesperson's word and not taking enough time to practice with the system, Robin feels EST did as good a job as it could have in selecting, installing, and implementing a new system. Required: (a) Do you agree that EST did a good job selecting, installing, and implementing the new system? Explain. (3 marks) (CLOI:PLOI:C4) (b) Do you feel EST could have done a better job? If so, what did it do wrong, and what should it have done differently? Justify. (9 marks) (CLOI:PLOI:C4) (C) (d) (e) Describes how could EST have avoided the missing features problem in the new system. (3 marks) (CLOI:PLOI:C4) Suggest how could EST can avoided conversion and reporting problems in new system. (6 marks) (CLOI:PLOI:C4) Evaluate Robin's economic feasibility analysis. Do you agree with his numbers and his conclusions? (5 marks) (CLOI:PLOI:C4) Examine how could EST's customers use the new multi-box shipping approach to defraud EST (3 marks) (CLOI:PLOI:C5) Assess how would you rate the service EST received from WSM in term of good and bad. (6 marks) (CLOI:PLOI:C5) (f)