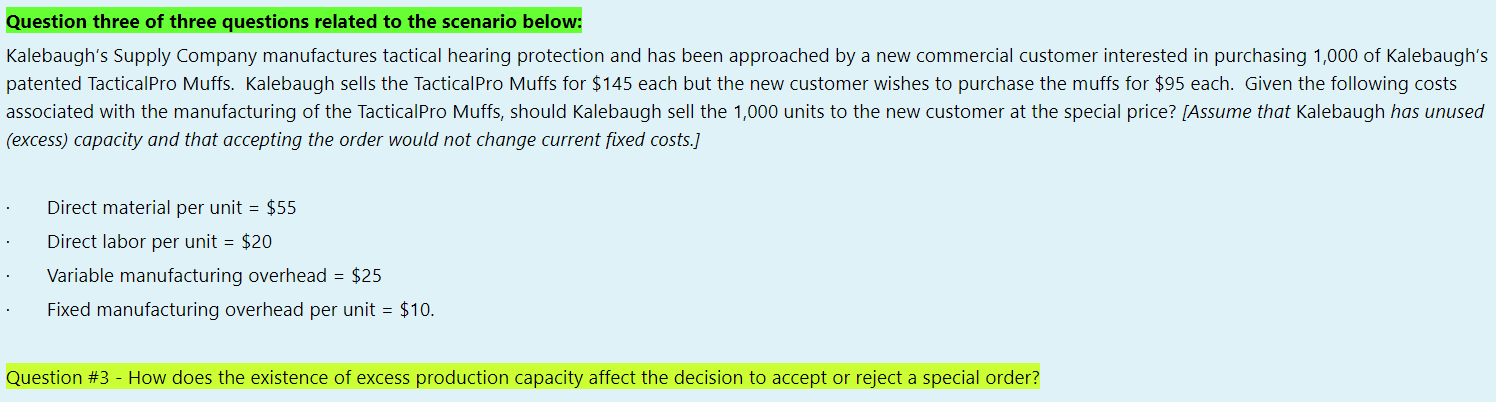

[Round all answers to the nearest cent ($0.00) and/or nearest hundredth percent (0.00%)] [Include your final answers in the text box below - even if answer is on attached working paper] [Upload your working papers in the space provided after each question or all at once after the last question on the exam (e.g. pic, scan, excel file, etc)] Question one of three questions related to the scenario below: Kalebaugh's Supply Company manufactures tactical hearing protection and has been approached by a new commercial customer interested in purchasing 1,000 of Kalebaugh's patented TacticalPro Muffs. Kalebaugh sells the TacticalPro Muffs for $145 each but the new customer wishes to purchase the muffs for $95 each. Given the following costs associated with the manufacturing of the TacticalPro Muffs, should Kalebaugh sell the 1,000 units to the new customer at the special price? [Assume that Kalebaugh has unused (excess) capacity and that accepting the order would not change current fixed costs. Direct material per unit = $55 Direct labor per unit = $20 Variable manufacturing overhead = $25 Fixed manufacturing overhead per unit = $10. Question #1 - Should Kalebaugh accept the offer? What would you recommend to Kalebaugh Supply? Why? [Support your answer quantitatively.] Question two of three questions related to the scenario below: Kalebaugh's Supply Company manufactures tactical hearing protection and has been approached by a new commercial customer interested in purchasing 1,000 of Kalebaugh's patented TacticalPro Muffs. Kalebaugh sells the TacticalPro Muffs for $145 each but the new customer wishes to purchase the muffs for $95 each. Given the following costs associated with the manufacturing of the TacticalPro Muffs, should Kalebaugh sell the 1,000 units to the new customer at the special price? [Assume that Kalebaugh has unused (excess) capacity and that accepting the order would not change current fixed costs. Direct material per unit = $55 Direct labor per unit = $20 Variable manufacturing overhead = $25 Fixed manufacturing overhead per unit = $10. Question #2 - What are two plausible strategic considerations before accepting or rejecting the special order? [Be sure to provide your rationale. Question three of three questions related to the scenario below: Kalebaugh's Supply Company manufactures tactical hearing protection and has been approached by a new commercial customer interested in purchasing 1,000 of Kalebaugh's patented TacticalPro Muffs. Kalebaugh sells the TacticalPro Muffs for $145 each but the new customer wishes to purchase the muffs for $95 each. Given the following costs associated with the manufacturing of the TacticalPro Muffs, should Kalebaugh sell the 1,000 units to the new customer at the special price? [Assume that Kalebaugh has unused (excess) capacity and that accepting the order would not change current fixed costs.] Direct material per unit = $55 Direct labor per unit = $20 Variable manufacturing overhead = $25 Fixed manufacturing overhead per unit = $10. Question #3 - How does the existence of excess production capacity affect the decision to accept or reject a special order