Answered step by step

Verified Expert Solution

Question

1 Approved Answer

1. The previous year's sales (2022) for the corresponding period were: 580 jackets July August 600 jackets September 650 jackets October November 850 jackets

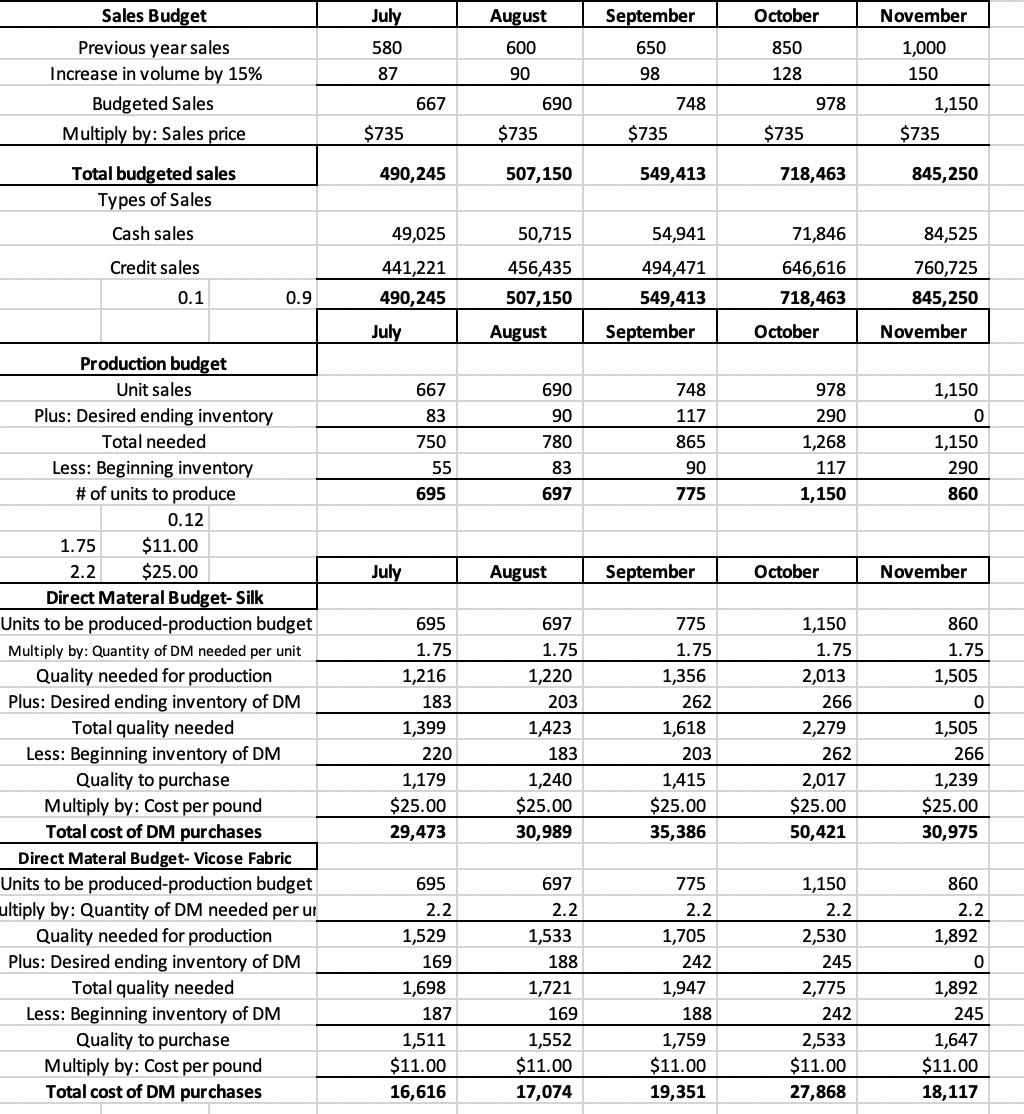

1. The previous year's sales (2022) for the corresponding period were: 580 jackets July August 600 jackets September 650 jackets October November 850 jackets 1,000 jackets 787250 The company expects the above volume of jacket sales to increase by 15% for the period July 2023 - November 2023. The budgeted selling price for 2023 is $735.00 XXper jacket. The company expects 10% of its sales to be cash (COD) sales. The remaining 90% of sales will be made on credit. Prepare a Sales Budget for H&BClothing. 2. The company desires to have finished goods inventory on hand at the end of each month equal to 12 percent of the following month's budgeted unit sales. Use the @ROUND function to round to the nearest whole number the number of jackets desired in ending inventory. On June 30, 2023, the company expects to have 55 jackets on hand. Use the @ROUND function to round to the nearest whole number the number of jacket units to produce. Prepare a Production budget. (NOTE: an estimate of sales in October is required to complete the production budget for September). 3. The jackets require two direct materials: silk fabric and viscose fabric for lining. Silk Silk fabric is purchased by the yard. 1.75 yards of silk fabric are required for each jacket produced. Management desires to have materials on hand at the end of each month equal to 15 percent of the following month's jacket production needs. Use the @ROUND function to round to the nearest whole number the number of yards 1 of silk desired in ending inventory. The beginning inventory of silk fabric, July 2023, is expected to be 220 yards. Silk fabric is expected to cost $25.00 per yard. Use the @ROUND function to round to the nearest whole number the number of yards of silk to purchase (DM to purchase). (NOTE: budgeted production in October is required in order to complete the direct materials budget for September.) Viscose for lining Viscose fabric is purchased by the roll of 10 yards. 2.2 yards of viscose fabric are required for each jacket produced. Management desires to have viscose fabric on hand at the end of each month equal to 11 percent of the following month's production needs. Use the @ROUND function to round to the nearest whole number the number of viscose yards desired in ending inventory. The beginning inventory, July 2023, is expected to be 187 yards. The roll of 10 yards is expected to cost $110. Use the @ROUND function to round to the nearest whole number the number of viscose fabric yards to purchase (DM to purchase). (NOTE: budgeted production in October is required to complete the direct materials budget for September.) Prepare a Direct Materials budget. Also, because two direct materials are required for production - silk and viscose fabric - you will need a separate schedule for each direct material. Sales Budget July August September October November Previous year sales Increase in volume by 15% 580 600 650 850 1,000 87 90 98 128 150 Budgeted Sales 667 690 748 978 1,150 Multiply by: Sales price $735 $735 $735 $735 $735 Total budgeted sales 490,245 507,150 549,413 718,463 845,250 Types of Sales Cash sales Credit sales 49,025 50,715 54,941 71,846 84,525 441,221 456,435 494,471 646,616 760,725 0.1 0.9 490,245 507,150 549,413 718,463 845,250 July August September October November Production budget Unit sales Plus: Desired ending inventory Total needed Less: Beginning inventory # of units to produce 0.12 1.75 $11.00 2.2 $25.00 667 690 748 978 1,150 83 90 117 290 0 750 780 865 1,268 1,150 55 83 90 117 290 695 697 775 1,150 860 July August September October November Direct Materal Budget-Silk Units to be produced-production budget 695 697 775 1,150 860 Multiply by: Quantity of DM needed per unit 1.75 1.75 1.75 1.75 1.75 Quality needed for production 1,216 1,220 1,356 2,013 1,505 Plus: Desired ending inventory of DM 183 203 262 266 0 Total quality needed 1,399 1,423 1,618 2,279 1,505 Less: Beginning inventory of DM 220 183 203 262 266 Quality to purchase 1,179 1,240 1,415 2,017 1,239 Multiply by: Cost per pound $25.00 $25.00 $25.00 $25.00 $25.00 Total cost of DM purchases 29,473 30,989 35,386 50,421 30,975 Direct Materal Budget- Vicose Fabric Units to be produced-production budget 695 697 775 1,150 860 ultiply by: Quantity of DM needed per ur 2.2 2.2 2.2 2.2 2.2 Quality needed for production 1,529 1,533 1,705 2,530 1,892 Plus: Desired ending inventory of DM 169 188 242 245 0 Total quality needed 1,698 1,721 1,947 2,775 1,892 Less: Beginning inventory of DM 187 169 188 242 Quality to purchase 1,511 1,552 1,759 Multiply by: Cost per pound $11.00 $11.00 $11.00 2,533 $11.00 245 1,647 $11.00 Total cost of DM purchases 16,616 17,074 19,351 27,868 18,117

Step by Step Solution

There are 3 Steps involved in it

Step: 1

Get Instant Access to Expert-Tailored Solutions

See step-by-step solutions with expert insights and AI powered tools for academic success

Step: 2

Step: 3

Ace Your Homework with AI

Get the answers you need in no time with our AI-driven, step-by-step assistance

Get Started