Question

Sandstorm Manufacturing Inc. makes two types of industrial component partsthe LE100 and the UL600. It annually produces 67,000 units of LE100 and 13,200 units of

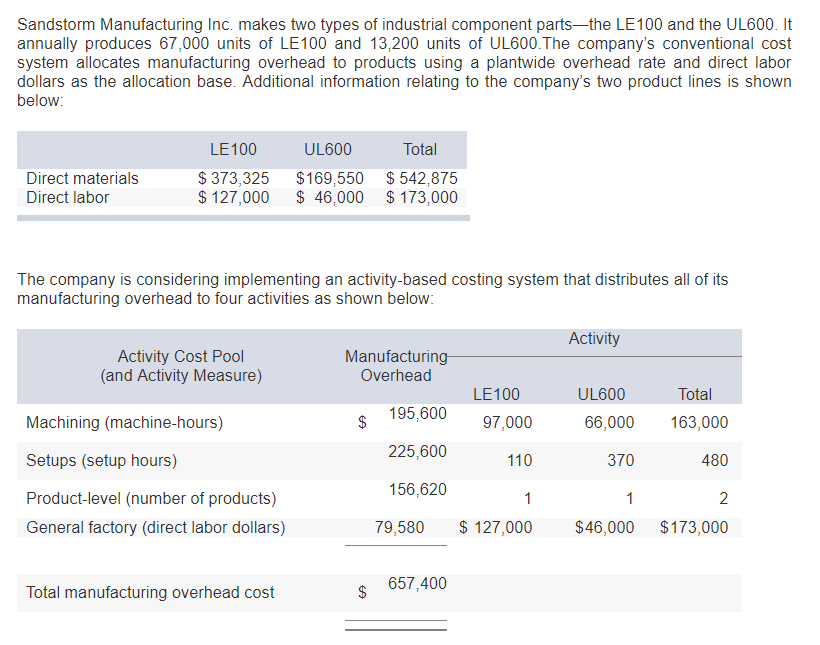

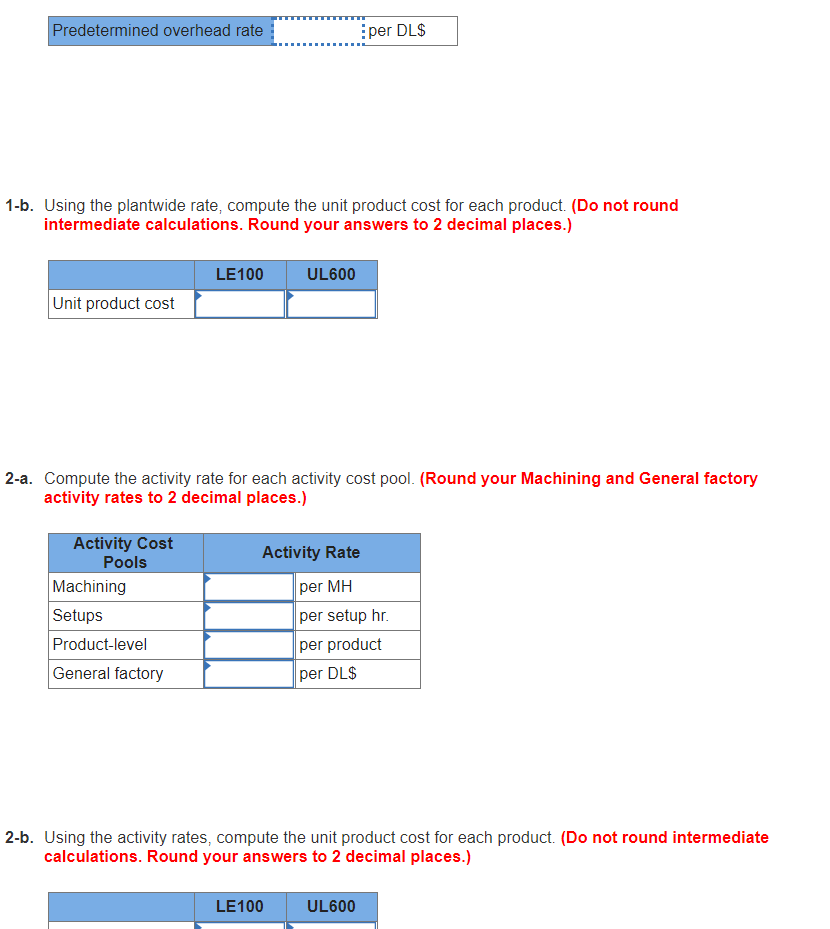

Sandstorm Manufacturing Inc. makes two types of industrial component partsthe LE100 and the UL600. It annually produces 67,000 units of LE100 and 13,200 units of UL600.The companys conventional cost system allocates manufacturing overhead to products using a plantwide overhead rate and direct labor dollars as the allocation base. Additional information relating to the companys two product lines is shown below: LE100 UL600 Total Direct materials $ 373,325 $ 169,550 $ 542,875 Direct labor $ 127,000 $ 46,000 $ 173,000 The company is considering implementing an activity-based costing system that distributes all of its manufacturing overhead to four activities as shown below: Activity Cost Pool (and Activity Measure) Manufacturing Overhead Activity LE100 UL600 Total Machining (machine-hours) $ 195,600 97,000 66,000 163,000 Setups (setup hours) 225,600 110 370 480 Product-level (number of products) 156,620 1 1 2 General factory (direct labor dollars) 79,580 $ 127,000 $ 46,000 $ 173,000 Total manufacturing overhead cost $ 657,400

Step by Step Solution

There are 3 Steps involved in it

Step: 1

Get Instant Access to Expert-Tailored Solutions

See step-by-step solutions with expert insights and AI powered tools for academic success

Step: 2

Step: 3

Ace Your Homework with AI

Get the answers you need in no time with our AI-driven, step-by-step assistance

Get Started