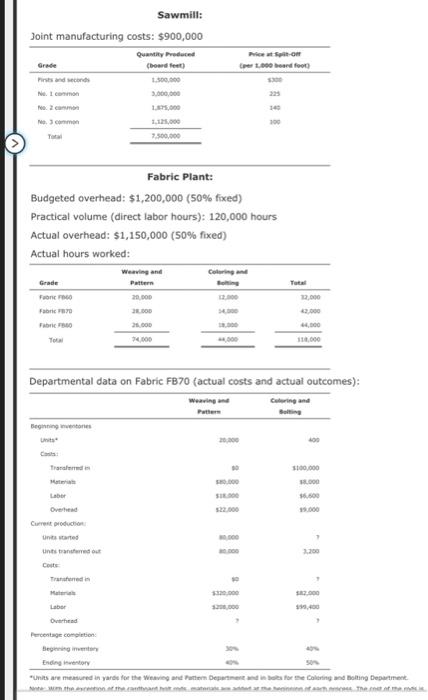

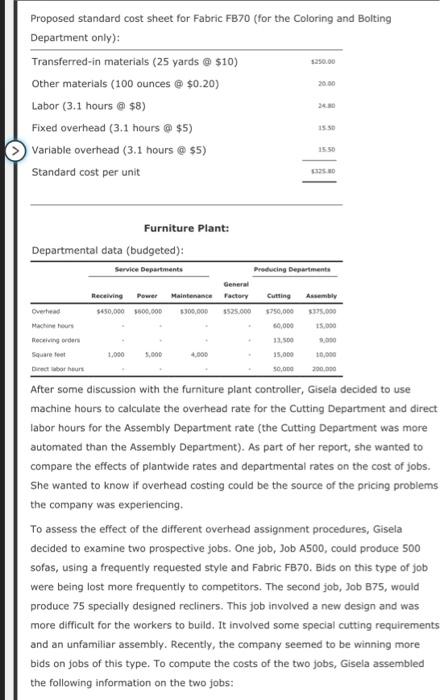

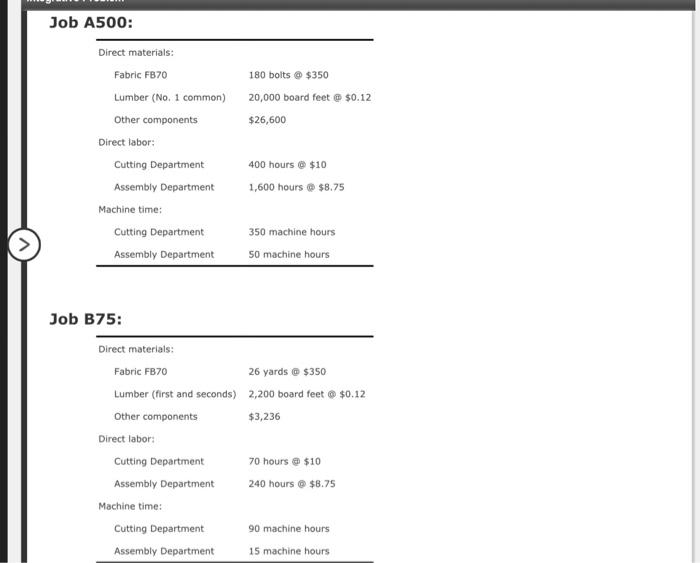

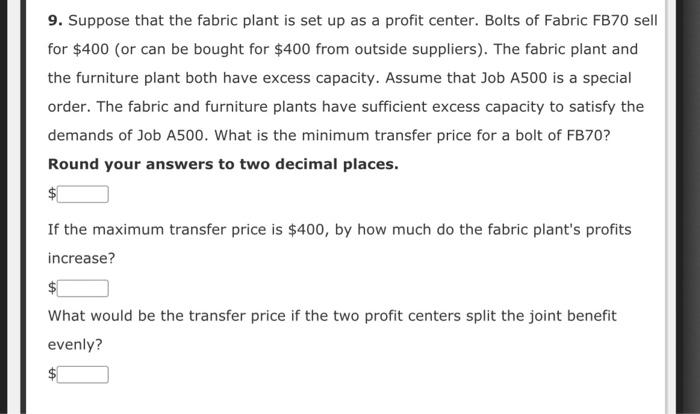

Sawmill: Joint manufacturing costs: $900,000 Fabric Plant: Budgeted overhead: $1,200,000 ( 50% fixed) Practical volume (direct labor hours): 120,000 hours Actual overhead: $1,150,000 ( 50% fixed) Actual hours worked: Departmental data on Fabric FB70 (actual costs and actual outcomes): Proposed standard cost sheet for Fabric FB70 (for the Coloring and Bolting Furniture Plant: Departmental data (budgeted): After some discussion with the furniture plant controller, Gisela decided to use machine hours to calculate the overhead rate for the Cutting Department and direct labor hours for the Assembly Department rate (the Cutting Department was more automated than the Assembly Department). As part of her report, she wanted to compare the effects of plantwide rates and departmental rates on the cost of jobs. She wanted to know if overhead costing could be the source of the pricing problems the company was experiencing. To assess the effect of the different overhead assignment procedures, Gisela decided to examine two prospective jobs. One job, Job A500, could produce 500 sofas, using a frequently requested style and Fabric FB70. Bids on this type of job were being lost more frequently to competitors. The second job, Job B75, would produce 75 specially designed recliners. This job involved a new design and was more difficult for the workers to build. It involved some special cutting requirements and an unfamiliar assembly. Recently, the company seemed to be winning more bids on jobs of this type. To compute the costs of the two jobs, Gisela assembled the following information on the two jobs: Job AEn. 9. Suppose that the fabric plant is set up as a profit center. Bolts of Fabric FB70 sell for $400 (or can be bought for $400 from outside suppliers). The fabric plant and the furniture plant both have excess capacity. Assume that Job A500 is a special order. The fabric and furniture plants have sufficient excess capacity to satisfy the demands of Job A500. What is the minimum transfer price for a bolt of FB70? Round your answers to two decimal places. $ If the maximum transfer price is $400, by how much do the fabric plant's profits increase? $ What would be the transfer price if the two profit centers split the joint benefit evenly? Sawmill: Joint manufacturing costs: $900,000 Fabric Plant: Budgeted overhead: $1,200,000 ( 50% fixed) Practical volume (direct labor hours): 120,000 hours Actual overhead: $1,150,000 ( 50% fixed) Actual hours worked: Departmental data on Fabric FB70 (actual costs and actual outcomes): Proposed standard cost sheet for Fabric FB70 (for the Coloring and Bolting Furniture Plant: Departmental data (budgeted): After some discussion with the furniture plant controller, Gisela decided to use machine hours to calculate the overhead rate for the Cutting Department and direct labor hours for the Assembly Department rate (the Cutting Department was more automated than the Assembly Department). As part of her report, she wanted to compare the effects of plantwide rates and departmental rates on the cost of jobs. She wanted to know if overhead costing could be the source of the pricing problems the company was experiencing. To assess the effect of the different overhead assignment procedures, Gisela decided to examine two prospective jobs. One job, Job A500, could produce 500 sofas, using a frequently requested style and Fabric FB70. Bids on this type of job were being lost more frequently to competitors. The second job, Job B75, would produce 75 specially designed recliners. This job involved a new design and was more difficult for the workers to build. It involved some special cutting requirements and an unfamiliar assembly. Recently, the company seemed to be winning more bids on jobs of this type. To compute the costs of the two jobs, Gisela assembled the following information on the two jobs: Job AEn. 9. Suppose that the fabric plant is set up as a profit center. Bolts of Fabric FB70 sell for $400 (or can be bought for $400 from outside suppliers). The fabric plant and the furniture plant both have excess capacity. Assume that Job A500 is a special order. The fabric and furniture plants have sufficient excess capacity to satisfy the demands of Job A500. What is the minimum transfer price for a bolt of FB70? Round your answers to two decimal places. $ If the maximum transfer price is $400, by how much do the fabric plant's profits increase? $ What would be the transfer price if the two profit centers split the joint benefit evenly