Answered step by step

Verified Expert Solution

Question

1 Approved Answer

Separations Processes Principles: Chapter 5 Question 5.4 The book solutions uses mole fractions to solve the answer but I believe mole ratios are easier. I'm

Separations Processes Principles: Chapter 5 Question 5.4

The book solutions uses mole fractions to solve the answer but I believe mole ratios are easier. I'm trying to see how it is done via that method if at all possible. If not, please go in depth into how the mole fractions are utilized to solve the problem as step 3 of the solution is very unclear in the book solutions.

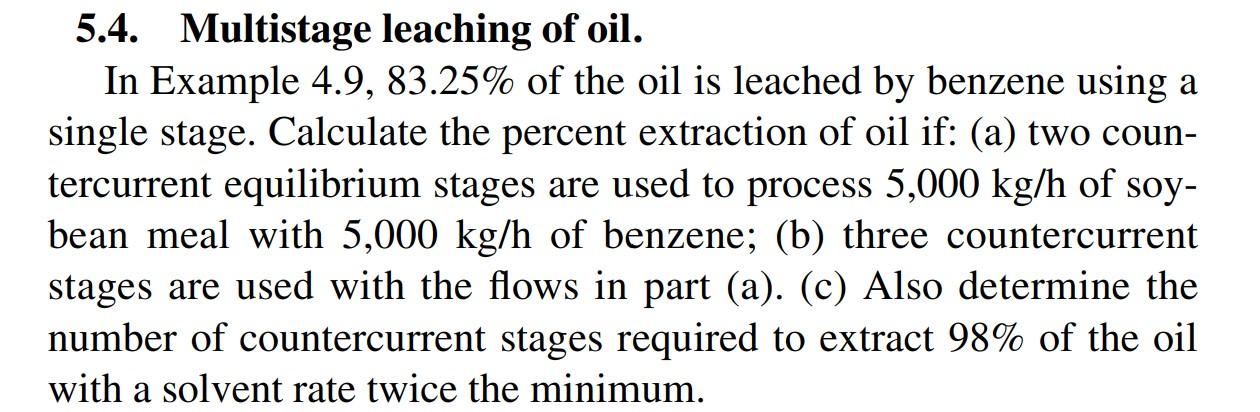

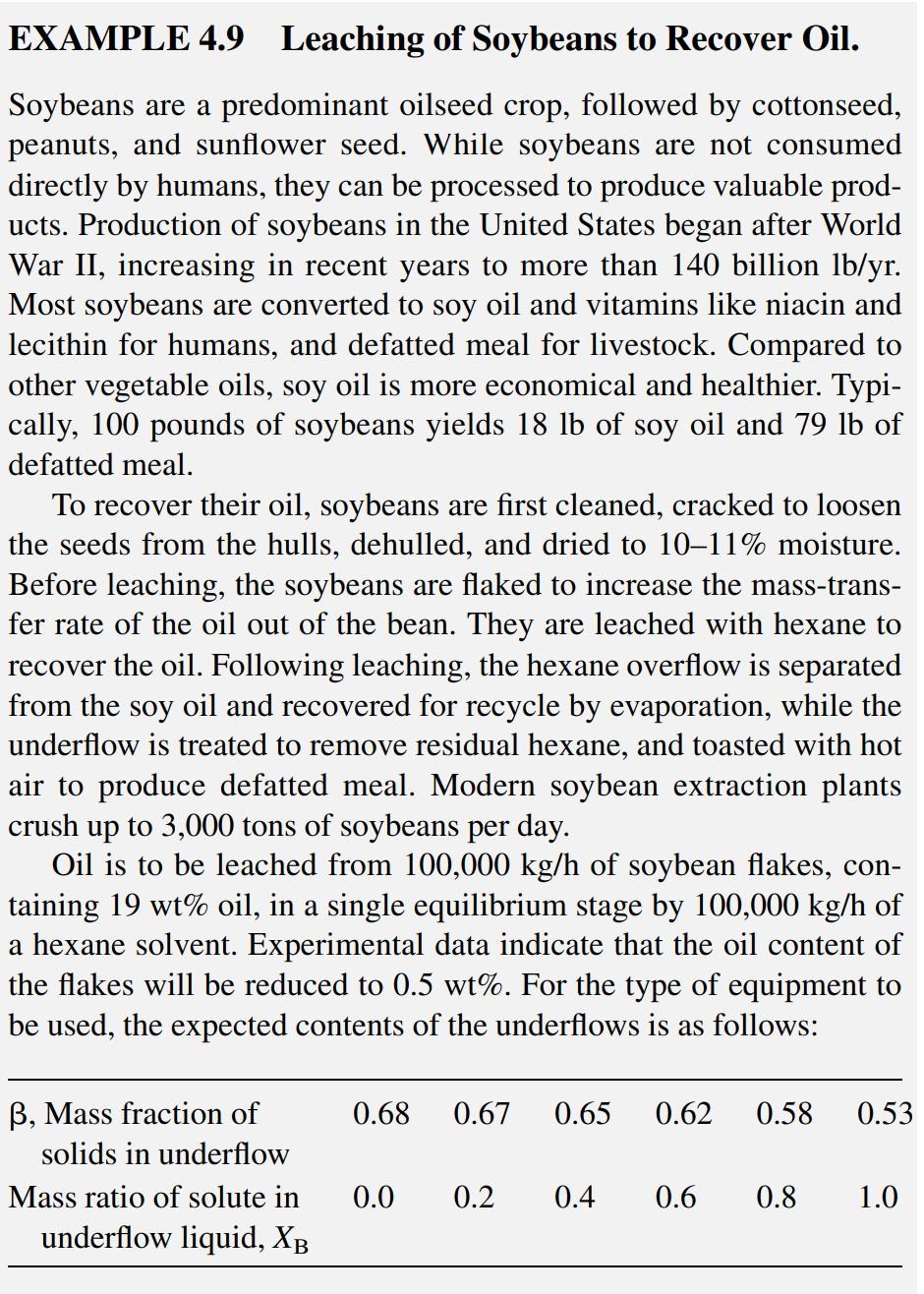

5.4. Multistage leaching of oil. In Example 4.9, 83.25% of the oil is leached by benzene using a single stage. Calculate the percent extraction of oil if: (a) two coun- tercurrent equilibrium stages are used to process 5,000 kg/h of soy- bean meal with 5,000 kg/h of benzene; (b) three countercurrent stages are used with the flows in part (a). (c) Also determine the number of countercurrent stages required to extract 98% of the oil with a solvent rate twice the minimum. EXAMPLE 4.9 Leaching of Soybeans to Recover Oil. Soybeans are a predominant oilseed crop, followed by cottonseed, peanuts, and sunflower seed. While soybeans are not consumed directly by humans, they can be processed to produce valuable prod- ucts. Production of soybeans in the United States began after World War II, increasing in recent years to more than 140 billion lb/yr. Most soybeans are converted to soy oil and vitamins like niacin and lecithin for humans, and defatted meal for livestock. Compared to other vegetable oils, soy oil is more economical and healthier. Typi- cally, 100 pounds of soybeans yields 18 lb of soy oil and 79 lb of defatted meal. To recover their oil, soybeans are first cleaned, cracked to loosen the seeds from the hulls, dehulled, and dried to 1011% moisture. Before leaching, the soybeans are flaked to increase the mass-trans- fer rate of the oil out of the bean. They are leached with hexane to recover the oil. Following leaching, the hexane overflow is separated from the soy oil and recovered for recycle by evaporation, while the underflow is treated to remove residual hexane, and toasted with hot air to produce defatted meal. Modern soybean extraction plants crush up to 3,000 tons of soybeans per day. Oil is to be leached from 100,000 kg/h of soybean flakes, con- taining 19 wt% oil, in a single equilibrium stage by 100,000 kg/h of a hexane solvent. Experimental data indicate that the oil content of the flakes will be reduced to 0.5 wt%. For the type of equipment to be used, the expected contents of the underflows is as follows: 0.68 0.67 0.65 0.62 0.58 0.53 B, Mass fraction of solids in underflow Mass ratio of solute in underflow liquid, XB 0.0 0.2 0.4 0.6 0.8 1.0Step by Step Solution

There are 3 Steps involved in it

Step: 1

Get Instant Access to Expert-Tailored Solutions

See step-by-step solutions with expert insights and AI powered tools for academic success

Step: 2

Step: 3

Ace Your Homework with AI

Get the answers you need in no time with our AI-driven, step-by-step assistance

Get Started