Answered step by step

Verified Expert Solution

Question

1 Approved Answer

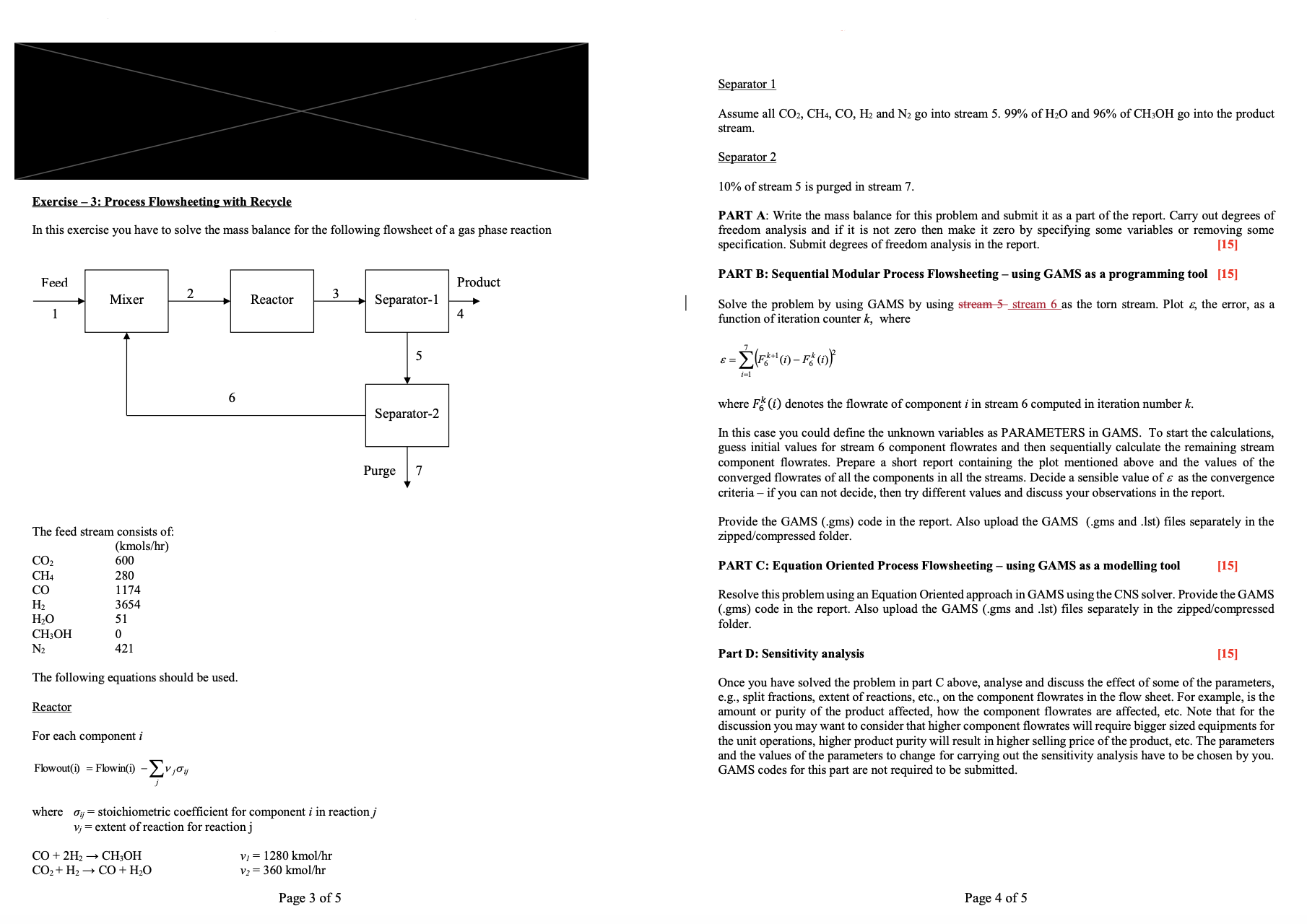

Separator 1 Assume all C O 2 , C H 4 , C O , H 2 and N 2 go into stream 5 .

Separator

Assume all and go into stream of and of go into the product

stream.

Separator

of stream is purged in stream

PART A: Write the mass balance for this problem and submit it as a part of the report. Carry out degrees of

freedom analysis and if it is not zero then make it zero by specifying some variables or removing some

specification. Submit degrees of freedom analysis in the report.

PART B: Sequential Modular Process Flowsheeting using GAMS as a programming tool

Solve the problem by using GAMS by using stream stream as the torn stream. Plot the error, as a

function of iteration counter where

where denotes the flowrate of component in stream computed in iteration number

In this case you could define the unknown variables as PARAMETERS in GAMS. To start the calculations,

guess initial values for stream component flowrates and then sequentially calculate the remaining stream

component flowrates. Prepare a short report containing the plot mentioned above and the values of the

converged flowrates of all the components in all the streams. Decide a sensible value of as the convergence

criteria if you can not decide, then try different values and discuss your observations in the report.

Provide the GAMS gms code in the report. Also upload the GAMS gms and lst files separately in the

zippedcompressed folder.

PART C: Equation Oriented Process Flowsheeting using GAMS as a modelling tool

Resolve this problem using an Equation Oriented approach in GAMS using the CNS solver. Provide the GAMS

gms code in the report. Also upload the GAMS gms and lst files separately in the zippedcompressed

folder.

Part D: Sensitivity analysis

Once you have solved the problem in part above, analyse and discuss the effect of some of the parameters,

eg split fractions, extent of reactions, etc., on the component flowrates in the flow sheet. For example, is the

amount or purity of the product affected, how the component flowrates are affected, etc. Note that for the

discussion you may want to consider that higher component flowrates will require bigger sized equipments for

the unit operations, higher product purity will result in higher selling price of the product, etc. The parameters

and the values of the parameters to change for carrying out the sensitivity analysis have to be chosen by you.

GAMS codes for this part are not required to be submitted.

Step by Step Solution

There are 3 Steps involved in it

Step: 1

Get Instant Access to Expert-Tailored Solutions

See step-by-step solutions with expert insights and AI powered tools for academic success

Step: 2

Step: 3

Ace Your Homework with AI

Get the answers you need in no time with our AI-driven, step-by-step assistance

Get Started