Answered step by step

Verified Expert Solution

Question

1 Approved Answer

Show the work and every step! Goodparts Co. The Goodparts Company produces a component that is subsequently used in the aerospace industry. The component consists

Show the work and every step!

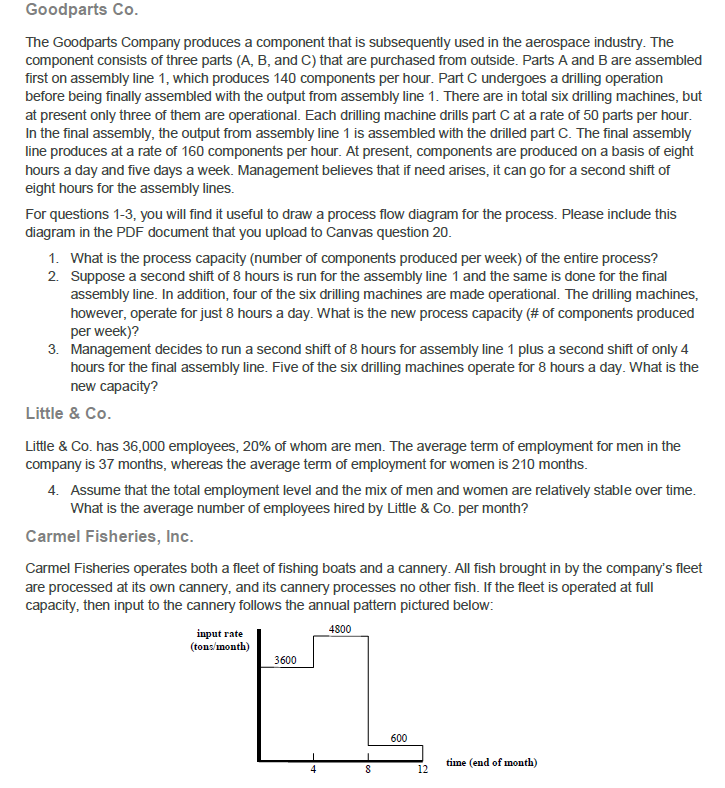

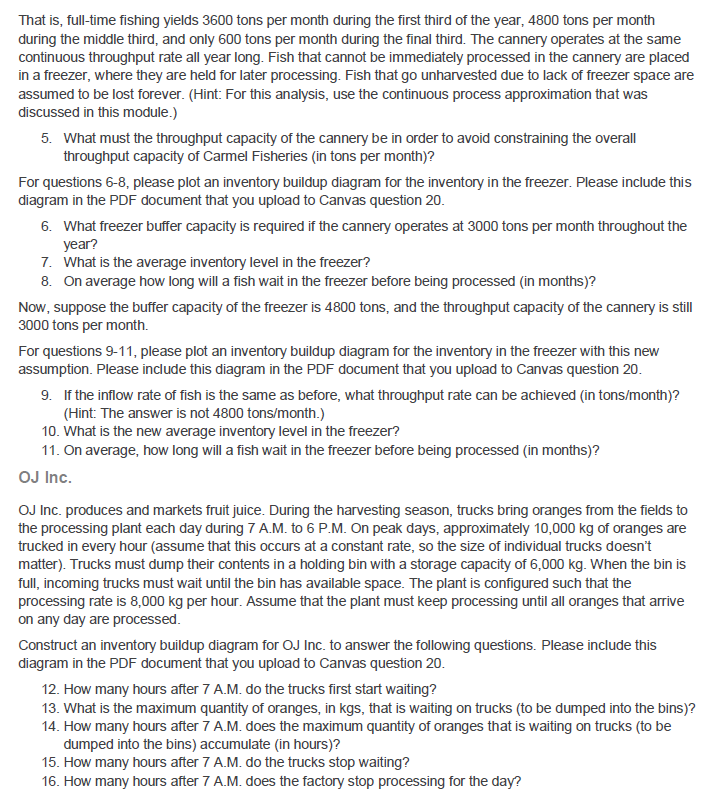

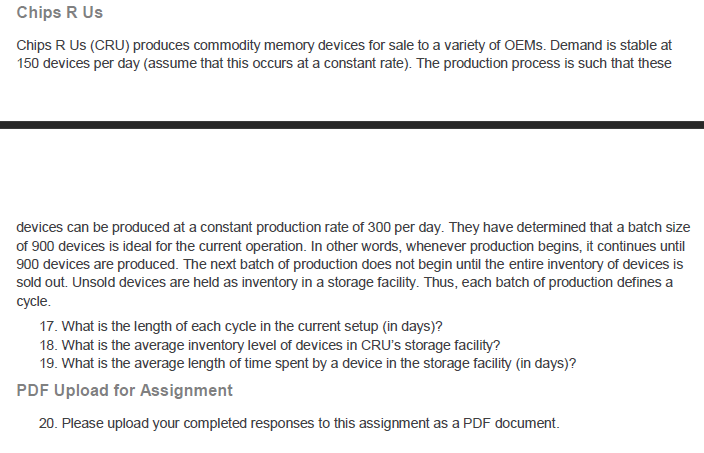

Goodparts Co. The Goodparts Company produces a component that is subsequently used in the aerospace industry. The component consists of three parts (A, B, and C) that are purchased from outside. Parts A and B are assembled first on assembly line 1, which produces 140 components per hour. Part C undergoes a drilling operation before being finally assembled with the output from assembly line 1 . There are in total six drilling machines, but at present only three of them are operational. Each drilling machine drills part C at a rate of 50 parts per hour. In the final assembly, the output from assembly line 1 is assembled with the drilled part C. The final assembly line produces at a rate of 160 components per hour. At present, components are produced on a basis of eight hours a day and five days a week. Management believes that if need arises, it can go for a second shift of eight hours for the assembly lines. For questions 1-3, you will find it useful to draw a process flow diagram for the process. Please include this diagram in the PDF document that you upload to Canvas question 20. 1. What is the process capacity (number of components produced per week) of the entire process? 2. Suppose a second shift of 8 hours is run for the assembly line 1 and the same is done for the final assembly line. In addition, four of the six drilling machines are made operational. The drilling machines, however, operate for just 8 hours a day. What is the new process capacity (\# of components produced per week)? 3. Management decides to run a second shift of 8 hours for assembly line 1 plus a second shift of only 4 hours for the final assembly line. Five of the six drilling machines operate for 8 hours a day. What is the new capacity? Little \& Co. Little \& Co. has 36,000 employees, 20% of whom are men. The average term of employment for men in the company is 37 months, whereas the average term of employment for women is 210 months. 4. Assume that the total employment level and the mix of men and women are relatively stable over time. What is the average number of employees hired by Little \& Co. per month? Carmel Fisheries, Inc. Carmel Fisheries operates both a fleet of fishing boats and a cannery. All fish brought in by the company's fleet are processed at its own cannery, and its cannery processes no other fish. If the fleet is operated at full capacity, then input to the cannery follows the annual pattern pictured below: ( (end of month) That is, full-time fishing yields 3600 tons per month during the first third of the year, 4800 tons per month during the middle third, and only 600 tons per month during the final third. The cannery operates at the same continuous throughput rate all year long. Fish that cannot be immediately processed in the cannery are placed in a freezer, where they are held for later processing. Fish that go unharvested due to lack of freezer space are assumed to be lost forever. (Hint: For this analysis, use the continuous process approximation that was discussed in this module.) 5. What must the throughput capacity of the cannery be in order to avoid constraining the overall throughput capacity of Carmel Fisheries (in tons per month)? For questions 6-8, please plot an inventory buildup diagram for the inventory in the freezer. Please include this diagram in the PDF document that you upload to Canvas question 20. 6. What freezer buffer capacity is required if the cannery operates at 3000 tons per month throughout the year? 7. What is the average inventory level in the freezer? 8. On average how long will a fish wait in the freezer before being processed (in months)? Now, suppose the buffer capacity of the freezer is 4800 tons, and the throughput capacity of the cannery is still 3000 tons per month. For questions 9-11, please plot an inventory buildup diagram for the inventory in the freezer with this new assumption. Please include this diagram in the PDF document that you upload to Canvas question 20. 9. If the inflow rate of fish is the same as before, what throughput rate can be achieved (in tons/month)? (Hint: The answer is not 4800 tons/month.) 10. What is the new average inventory level in the freezer? 11. On average, how long will a fish wait in the freezer before being processed (in months)? OJ Inc. OJ Inc. produces and markets fruit juice. During the harvesting season, trucks bring oranges from the fields to the processing plant each day during 7 A.M. to 6 P.M. On peak days, approximately 10,000kg of oranges are trucked in every hour (assume that this occurs at a constant rate, so the size of individual trucks doesn't matter). Trucks must dump their contents in a holding bin with a storage capacity of 6,000kg. When the bin is full, incoming trucks must wait until the bin has available space. The plant is configured such that the processing rate is 8,000kg per hour. Assume that the plant must keep processing until all oranges that arrive on any day are processed. Construct an inventory buildup diagram for OJ Inc. to answer the following questions. Please include this diagram in the PDF document that you upload to Canvas question 20. 12. How many hours after 7 A.M. do the trucks first start waiting? 13. What is the maximum quantity of oranges, in kgs, that is waiting on trucks (to be dumped into the bins)? 14. How many hours after 7 A.M. does the maximum quantity of oranges that is waiting on trucks (to be dumped into the bins) accumulate (in hours)? 15. How many hours after 7 A.M. do the trucks stop waiting? 16. How many hours after 7 A.M. does the factory stop processing for the day? Chips R Us Chips R Us (CRU) produces commodity memory devices for sale to a variety of OEMs. Demand is stable at 150 devices per day (assume that this occurs at a constant rate). The production process is such that these devices can be produced at a constant production rate of 300 per day. They have determined that a batch size of 900 devices is ideal for the current operation. In other words, whenever production begins, it continues until 900 devices are produced. The next batch of production does not begin until the entire inventory of devices is sold out. Unsold devices are held as inventory in a storage facility. Thus, each batch of production defines a cycle. 17. What is the length of each cycle in the current setup (in days)? 18. What is the average inventory level of devices in CRU's storage facility? 19. What is the average length of time spent by a device in the storage facility (in days)? PDF Upload for Assignment 20. Please upload your completed responses to this assignment as a PDF documentStep by Step Solution

There are 3 Steps involved in it

Step: 1

Get Instant Access to Expert-Tailored Solutions

See step-by-step solutions with expert insights and AI powered tools for academic success

Step: 2

Step: 3

Ace Your Homework with AI

Get the answers you need in no time with our AI-driven, step-by-step assistance

Get Started