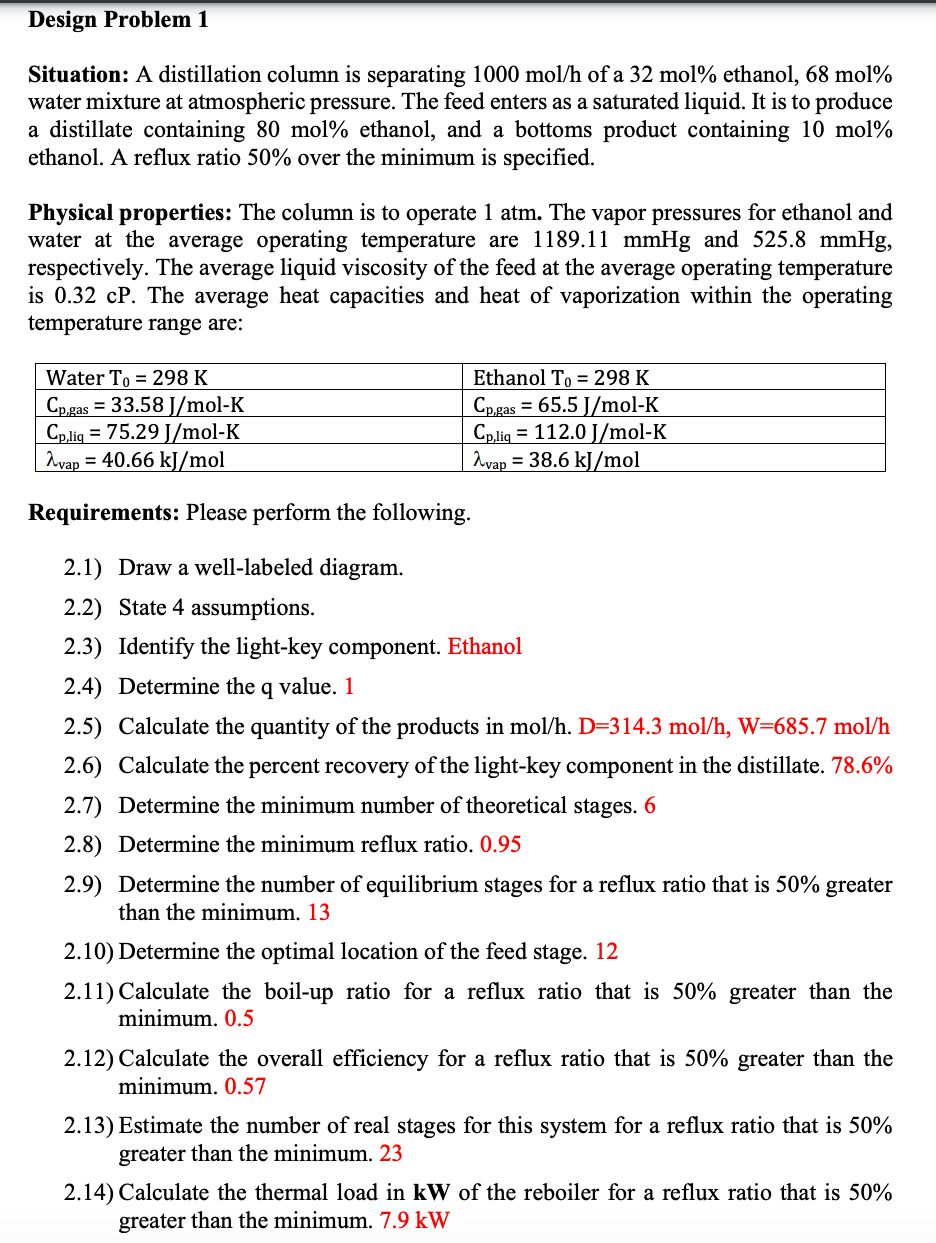

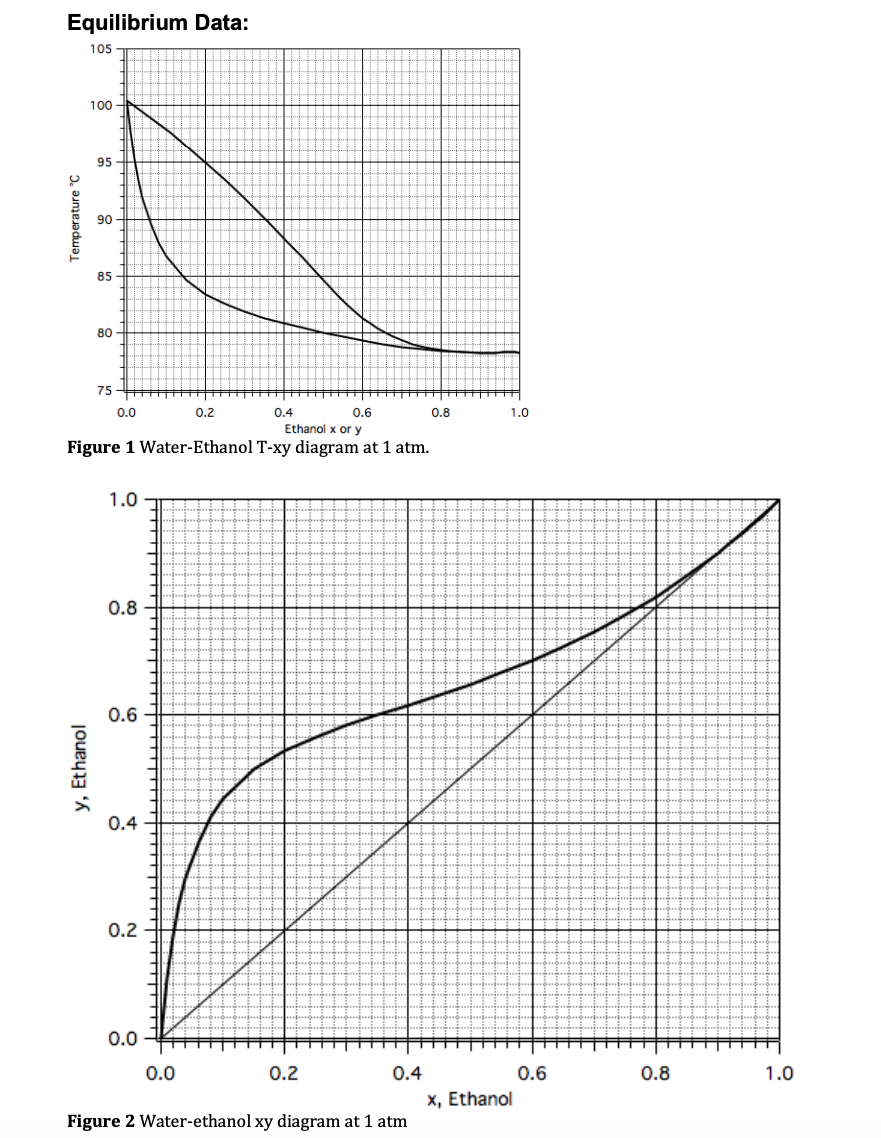

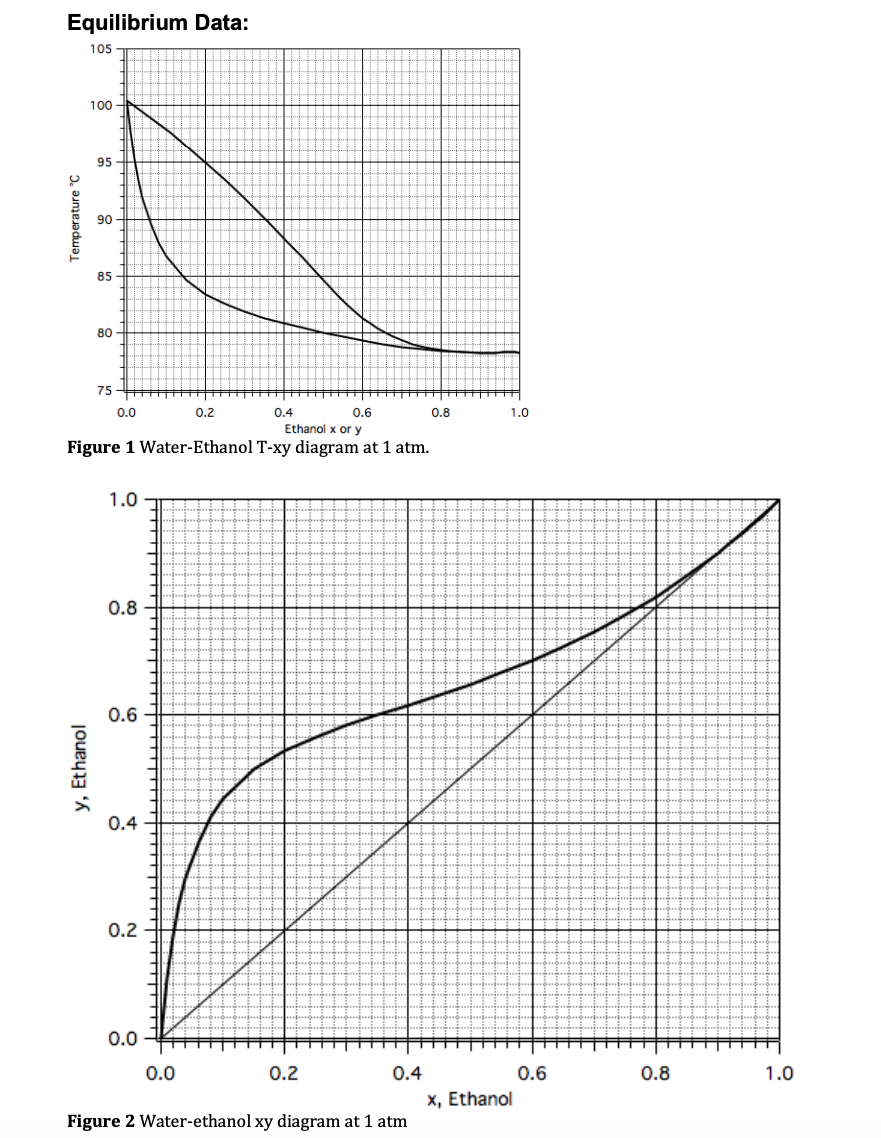

Situation: A distillation column is separating 1000mol/h of a 32mol% ethanol, 68mol% water mixture at atmospheric pressure. The feed enters as a saturated liquid. It is to produce a distillate containing 80mol% ethanol, and a bottoms product containing 10mol% ethanol. A reflux ratio 50% over the minimum is specified. Physical properties: The column is to operate 1atm. The vapor pressures for ethanol and water at the average operating temperature are 1189.11mmHg and 525.8mmHg, respectively. The average liquid viscosity of the feed at the average operating temperature is 0.32cP. The average heat capacities and heat of vaporization within the operating temperature range are: Requirements: Please perform the following. 2.1) Draw a well-labeled diagram. 2.2) State 4 assumptions. 2.3) Identify the light-key component. Ethanol 2.4) Determine the q value. 1 2.5) Calculate the quantity of the products in mol/h.D=314.3mol/h,W=685.7mol/h 2.6) Calculate the percent recovery of the light-key component in the distillate. 78.6% 2.7) Determine the minimum number of theoretical stages. 6 2.8) Determine the minimum reflux ratio. 0.95 2.9) Determine the number of equilibrium stages for a reflux ratio that is 50% greater than the minimum. 13 2.10) Determine the optimal location of the feed stage. 12 2.11) Calculate the boil-up ratio for a reflux ratio that is 50% greater than the minimum. 0.5 2.12) Calculate the overall efficiency for a reflux ratio that is 50% greater than the minimum. 0.57 2.13) Estimate the number of real stages for this system for a reflux ratio that is 50% greater than the minimum. 23 2.14) Calculate the thermal load in kW of the reboiler for a reflux ratio that is 50% greater than the minimum. 7.9kW Equilibrium Data: Situation: A distillation column is separating 1000mol/h of a 32mol% ethanol, 68mol% water mixture at atmospheric pressure. The feed enters as a saturated liquid. It is to produce a distillate containing 80mol% ethanol, and a bottoms product containing 10mol% ethanol. A reflux ratio 50% over the minimum is specified. Physical properties: The column is to operate 1atm. The vapor pressures for ethanol and water at the average operating temperature are 1189.11mmHg and 525.8mmHg, respectively. The average liquid viscosity of the feed at the average operating temperature is 0.32cP. The average heat capacities and heat of vaporization within the operating temperature range are: Requirements: Please perform the following. 2.1) Draw a well-labeled diagram. 2.2) State 4 assumptions. 2.3) Identify the light-key component. Ethanol 2.4) Determine the q value. 1 2.5) Calculate the quantity of the products in mol/h.D=314.3mol/h,W=685.7mol/h 2.6) Calculate the percent recovery of the light-key component in the distillate. 78.6% 2.7) Determine the minimum number of theoretical stages. 6 2.8) Determine the minimum reflux ratio. 0.95 2.9) Determine the number of equilibrium stages for a reflux ratio that is 50% greater than the minimum. 13 2.10) Determine the optimal location of the feed stage. 12 2.11) Calculate the boil-up ratio for a reflux ratio that is 50% greater than the minimum. 0.5 2.12) Calculate the overall efficiency for a reflux ratio that is 50% greater than the minimum. 0.57 2.13) Estimate the number of real stages for this system for a reflux ratio that is 50% greater than the minimum. 23 2.14) Calculate the thermal load in kW of the reboiler for a reflux ratio that is 50% greater than the minimum. 7.9kW Equilibrium Data