Solutions pls

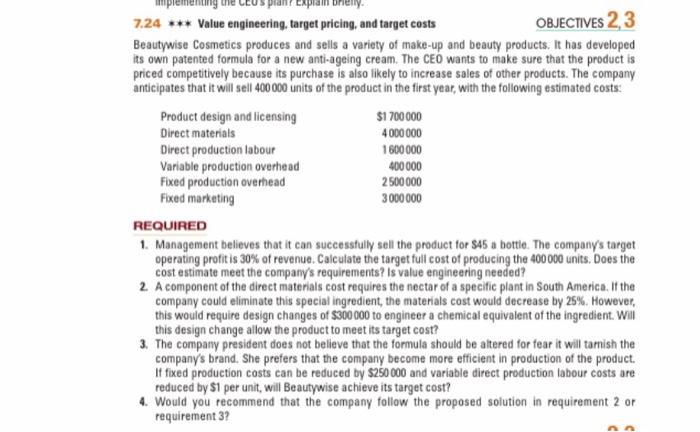

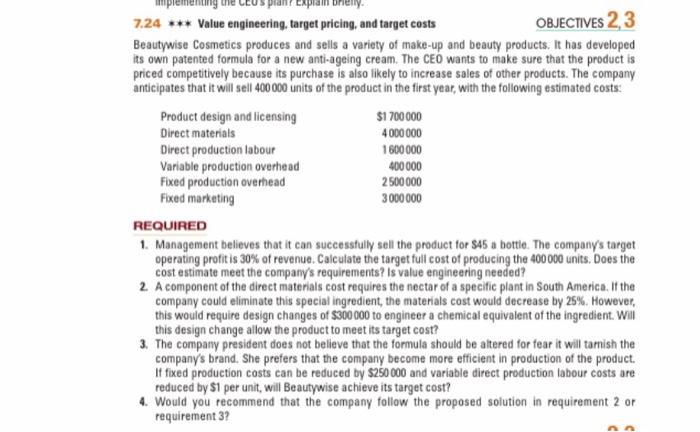

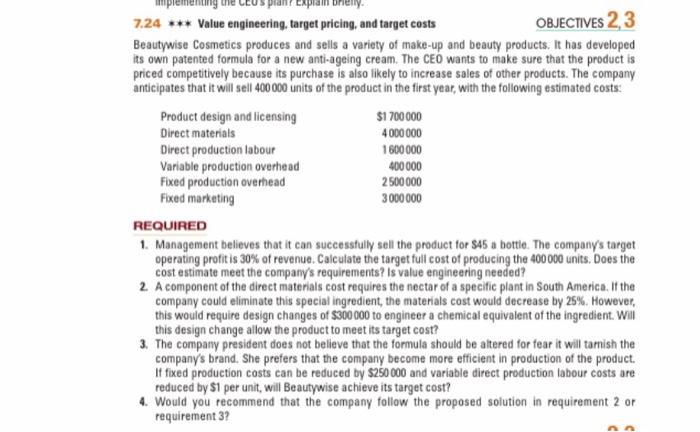

7.24 *** Value engineering, target pricing, and target costs OBJECTIVES 2,3 Beautywise Cosmetics produces and sells a variety of make-up and beauty products. It has developed its own patented formula for a new anti-ageing cream. The CEO wants to make sure that the product is priced competitively because its purchase is also likely to increase sales of other products. The company anticipates that it will sell 400000 units of the product in the first year, with the following estimated costs: Product design and licensing $1 700 000 Direct materials 4000000 Direct production labour 1600000 Variable production overhead 400 000 Fixed production overhead 2500000 Fixed marketing 3000000 REQUIRED 1. Management believes that it can successfully sell the product for $45 a bottle. The company's target operating profit is 30% of revenue. Calculate the target full cost of producing the 400 000 units. Does the cost estimate meet the company's requirements? Is value engineering needed? 2. A component of the direct materials cost requires the nectar of a specific plant in South America. If the company could eliminate this special ingredient, the materials cost would decrease by 25%. However, this would require design changes of $300 000 to engineer a chemical equivalent of the ingredient. Will this design change allow the product to meet its target cost? 3. The company president does not believe that the formula should be altered for fear it will tamish the company's brand. She prefers that the company become more efficient in production of the product. If fixed production costs can be reduced by S250 000 and variable direct production labour costs are reduced by $1 per unit, will Beautywise achieve its target cost? 4. Would you recommend that the company follow the proposed solution in requirement 2 or requirement 3? 7.24 *** Value engineering, target pricing, and target costs OBJECTIVES 2,3 Beautywise Cosmetics produces and sells a variety of make-up and beauty products. It has developed its own patented formula for a new anti-ageing cream. The CEO wants to make sure that the product is priced competitively because its purchase is also likely to increase sales of other products. The company anticipates that it will sell 400000 units of the product in the first year, with the following estimated costs: Product design and licensing $1 700 000 Direct materials 4000000 Direct production labour 1600000 Variable production overhead 400 000 Fixed production overhead 2500000 Fixed marketing 3000000 REQUIRED 1. Management believes that it can successfully sell the product for $45 a bottle. The company's target operating profit is 30% of revenue. Calculate the target full cost of producing the 400 000 units. Does the cost estimate meet the company's requirements? Is value engineering needed? 2. A component of the direct materials cost requires the nectar of a specific plant in South America. If the company could eliminate this special ingredient, the materials cost would decrease by 25%. However, this would require design changes of $300 000 to engineer a chemical equivalent of the ingredient. Will this design change allow the product to meet its target cost? 3. The company president does not believe that the formula should be altered for fear it will tamish the company's brand. She prefers that the company become more efficient in production of the product. If fixed production costs can be reduced by S250 000 and variable direct production labour costs are reduced by $1 per unit, will Beautywise achieve its target cost? 4. Would you recommend that the company follow the proposed solution in requirement 2 or requirement 3