Question: solve 8.5 with 8.3 problem Problem 8.5. Extraction of diphenylhexane from docosane with furfural. At 45C,1,000kg/h of a mixture of 0.80 mass fraction docosane and

solve 8.5 with 8.3 problem

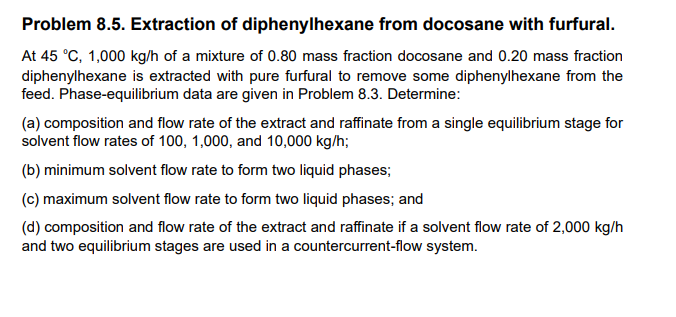

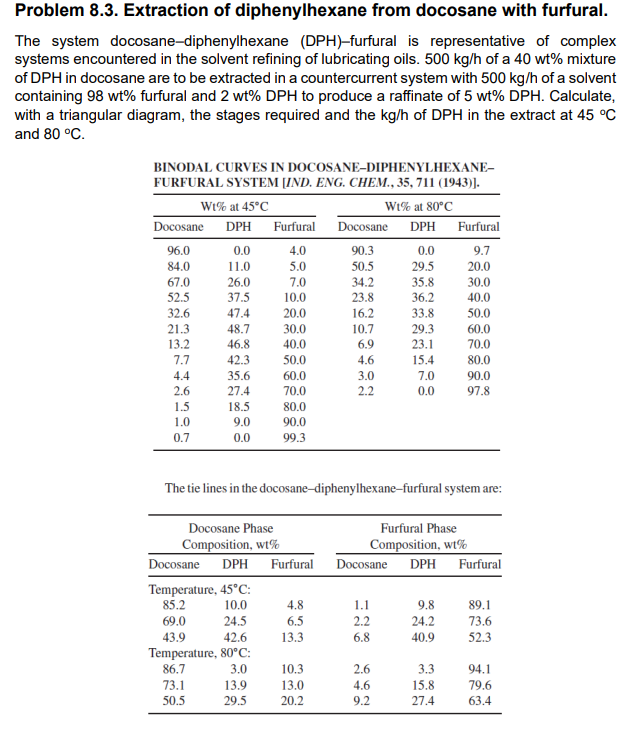

Problem 8.5. Extraction of diphenylhexane from docosane with furfural. At 45C,1,000kg/h of a mixture of 0.80 mass fraction docosane and 0.20 mass fraction diphenylhexane is extracted with pure furfural to remove some diphenylhexane from the feed. Phase-equilibrium data are given in Problem 8.3. Determine: (a) composition and flow rate of the extract and raffinate from a single equilibrium stage for solvent flow rates of 100,1,000, and 10,000kg/h; (b) minimum solvent flow rate to form two liquid phases; (c) maximum solvent flow rate to form two liquid phases; and (d) composition and flow rate of the extract and raffinate if a solvent flow rate of 2,000 kg/h and two equilibrium stages are used in a countercurrent-flow system. Problem 8.3. Extraction of diphenylhexane from docosane with furfural. The system docosane-diphenylhexane (DPH)-furfural is representative of complex systems encountered in the solvent refining of lubricating oils. 500kg/h of a 40wt% mixture of DPH in docosane are to be extracted in a countercurrent system with 500kg/h of a solvent containing 98wt% furfural and 2wt%DPH to produce a raffinate of 5wt%DPH. Calculate, with a triangular diagram, the stages required and the kg/h of DPH in the extract at 45C and 80C. BINODAL CURVES IN DOCOSANE-DIPHENYLHEXANE- EIDEIDAT SVSTEMIINO FNC CHEM 25711610421 The tie lines in the docosane-diphenylhexane-furfural system are: Problem 8.5. Extraction of diphenylhexane from docosane with furfural. At 45C,1,000kg/h of a mixture of 0.80 mass fraction docosane and 0.20 mass fraction diphenylhexane is extracted with pure furfural to remove some diphenylhexane from the feed. Phase-equilibrium data are given in Problem 8.3. Determine: (a) composition and flow rate of the extract and raffinate from a single equilibrium stage for solvent flow rates of 100,1,000, and 10,000kg/h; (b) minimum solvent flow rate to form two liquid phases; (c) maximum solvent flow rate to form two liquid phases; and (d) composition and flow rate of the extract and raffinate if a solvent flow rate of 2,000 kg/h and two equilibrium stages are used in a countercurrent-flow system. Problem 8.3. Extraction of diphenylhexane from docosane with furfural. The system docosane-diphenylhexane (DPH)-furfural is representative of complex systems encountered in the solvent refining of lubricating oils. 500kg/h of a 40wt% mixture of DPH in docosane are to be extracted in a countercurrent system with 500kg/h of a solvent containing 98wt% furfural and 2wt%DPH to produce a raffinate of 5wt%DPH. Calculate, with a triangular diagram, the stages required and the kg/h of DPH in the extract at 45C and 80C. BINODAL CURVES IN DOCOSANE-DIPHENYLHEXANE- EIDEIDAT SVSTEMIINO FNC CHEM 25711610421 The tie lines in the docosane-diphenylhexane-furfural system are

Step by Step Solution

There are 3 Steps involved in it

Get step-by-step solutions from verified subject matter experts