Answered step by step

Verified Expert Solution

Question

1 Approved Answer

solve all parts 2.3 Every year, significant quantities of plastic wastes are disposed off to landfills. An emerging processing technique for reclaiming plastic waste is

solve all parts

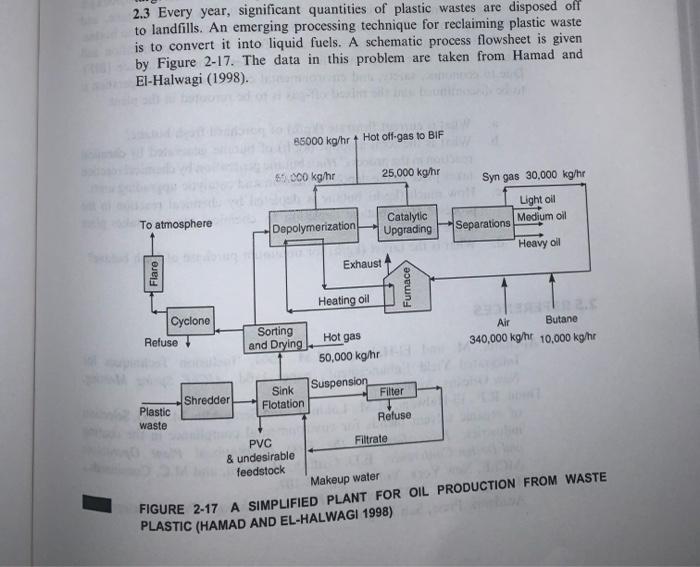

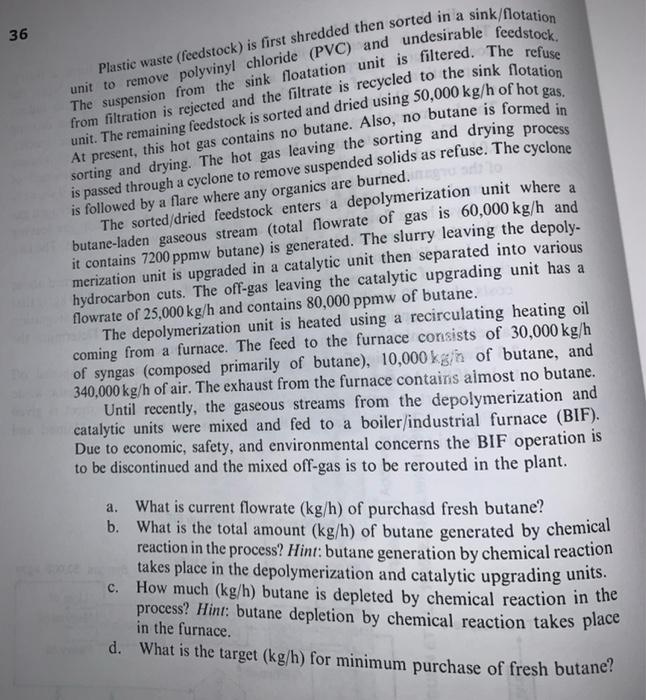

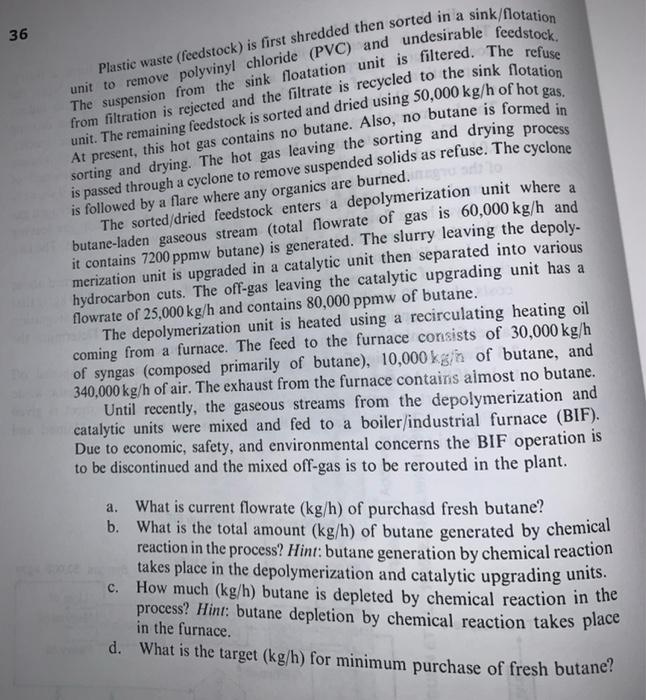

2.3 Every year, significant quantities of plastic wastes are disposed off to landfills. An emerging processing technique for reclaiming plastic waste is to convert it into liquid fuels. A schematic process flowsheet is given by Figure 2-17. The data in this problem are taken from Hamad and El-Halwagi (1998). 85000 kg/hr + Hot off-gas to BIF 65.000 kg/hr 25,000 kg/hr Syn gas 30,000 kg/hr Light oil Separations Medium oil Heavy oll To atmosphere Catalytic Upgrading Depolymerization Exhaust Flare Furnace Heating oil Cyclone Refuse Air Butane 340,000 kg/h 10,000 kg/h Sorting Hot gas and Drying 50,000 kg/hr Sink Suspension Filter Flotation Refuse Shredder Plastic waste PVC Filtrate & undesirable feedstock Makeup water FIGURE 2-17 A SIMPLIFIED PLANT FOR OIL PRODUCTION FROM WASTE PLASTIC (HAMAD AND EL-HALWAGI 1998) 36 Plastic waste (feedstock) is first shredded then sorted in a sink/Notation unit to remove polyvinyl chloride (PVC) and undesirable feedstock, The suspension from the sink floatation unit is filtered. The refuse from filtration is rejected and the filtrate is recycled to the sink flotation unit. The remaining feedstock is sorted and dried using 50,000 kg/h of hot gas. At present, this hot gas contains no butane. Also, no butane is formed in sorting and drying. The hot gas leaving the sorting and drying process is passed through a cyclone to remove suspended solids as refuse. The cyclone is followed by a flare where any organics are burned. The sorted/dried feedstock enters a depolymerization unit where a butane-laden gaseous stream (total flowrate of gas is 60,000 kg/h and it contains 7200 ppmw butane) is generated. The slurry leaving the depoly- merization unit is upgraded in a catalytic unit then separated into various hydrocarbon cuts. The off-gas leaving the catalytic upgrading unit has a flowrate of 25,000 kg/h and contains 80,000 ppmw of butane. The depolymerization unit is heated using a recirculating heating oil coming from a furnace. The feed to the furnace consists of 30,000 kg/h of syngas (composed primarily of butane), 10,000 kgin of butane, and 340,000 kg/h of air. The exhaust from the furnace contains almost no butane. Until recently, the gaseous streams from the depolymerization and catalytic units were mixed and fed to a boiler/industrial furnace (BIF). Due to economic, safety, and environmental concerns the BIF operation is to be discontinued and the mixed off-gas is to be rerouted in the plant. a. What is current flowrate (kg/h) of purchasd fresh butane? b. What is the total amount (kg/h) of butane generated by chemical reaction in the process? Hint: butane generation by chemical reaction takes place in the depolymerization and catalytic upgrading units. How much (kg/h) butane is depleted by chemical reaction in the process? Hint: butane depletion by chemical reaction takes place in the furnace. d. What is the target (kg/h) for minimum purchase of fresh butane? c. 2.3 Every year, significant quantities of plastic wastes are disposed off to landfills. An emerging processing technique for reclaiming plastic waste is to convert it into liquid fuels. A schematic process flowsheet is given by Figure 2-17. The data in this problem are taken from Hamad and El-Halwagi (1998). 85000 kg/hr + Hot off-gas to BIF 65.000 kg/hr 25,000 kg/hr Syn gas 30,000 kg/hr Light oil Separations Medium oil Heavy oll To atmosphere Catalytic Upgrading Depolymerization Exhaust Flare Furnace Heating oil Cyclone Refuse Air Butane 340,000 kg/h 10,000 kg/h Sorting Hot gas and Drying 50,000 kg/hr Sink Suspension Filter Flotation Refuse Shredder Plastic waste PVC Filtrate & undesirable feedstock Makeup water FIGURE 2-17 A SIMPLIFIED PLANT FOR OIL PRODUCTION FROM WASTE PLASTIC (HAMAD AND EL-HALWAGI 1998) 36 Plastic waste (feedstock) is first shredded then sorted in a sink/Notation unit to remove polyvinyl chloride (PVC) and undesirable feedstock, The suspension from the sink floatation unit is filtered. The refuse from filtration is rejected and the filtrate is recycled to the sink flotation unit. The remaining feedstock is sorted and dried using 50,000 kg/h of hot gas. At present, this hot gas contains no butane. Also, no butane is formed in sorting and drying. The hot gas leaving the sorting and drying process is passed through a cyclone to remove suspended solids as refuse. The cyclone is followed by a flare where any organics are burned. The sorted/dried feedstock enters a depolymerization unit where a butane-laden gaseous stream (total flowrate of gas is 60,000 kg/h and it contains 7200 ppmw butane) is generated. The slurry leaving the depoly- merization unit is upgraded in a catalytic unit then separated into various hydrocarbon cuts. The off-gas leaving the catalytic upgrading unit has a flowrate of 25,000 kg/h and contains 80,000 ppmw of butane. The depolymerization unit is heated using a recirculating heating oil coming from a furnace. The feed to the furnace consists of 30,000 kg/h of syngas (composed primarily of butane), 10,000 kgin of butane, and 340,000 kg/h of air. The exhaust from the furnace contains almost no butane. Until recently, the gaseous streams from the depolymerization and catalytic units were mixed and fed to a boiler/industrial furnace (BIF). Due to economic, safety, and environmental concerns the BIF operation is to be discontinued and the mixed off-gas is to be rerouted in the plant. a. What is current flowrate (kg/h) of purchasd fresh butane? b. What is the total amount (kg/h) of butane generated by chemical reaction in the process? Hint: butane generation by chemical reaction takes place in the depolymerization and catalytic upgrading units. How much (kg/h) butane is depleted by chemical reaction in the process? Hint: butane depletion by chemical reaction takes place in the furnace. d. What is the target (kg/h) for minimum purchase of fresh butane? c

Step by Step Solution

There are 3 Steps involved in it

Step: 1

Get Instant Access to Expert-Tailored Solutions

See step-by-step solutions with expert insights and AI powered tools for academic success

Step: 2

Step: 3

Ace Your Homework with AI

Get the answers you need in no time with our AI-driven, step-by-step assistance

Get Started