solve for all the Q

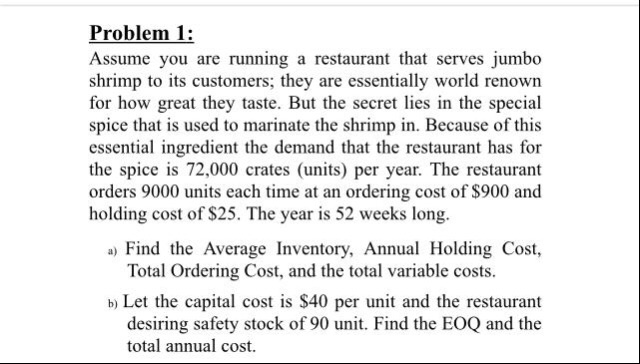

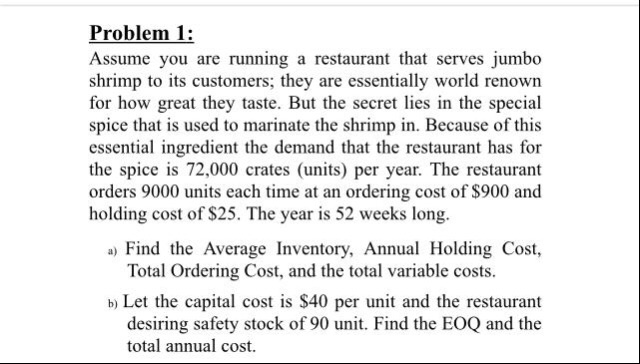

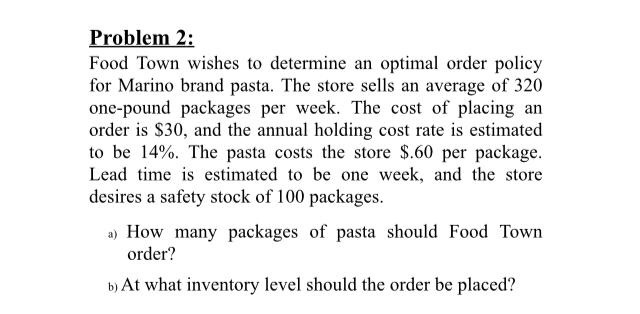

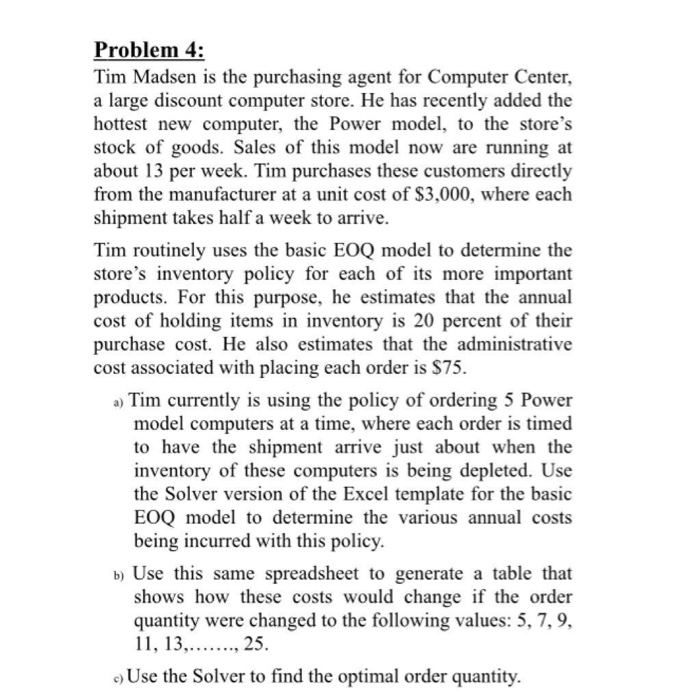

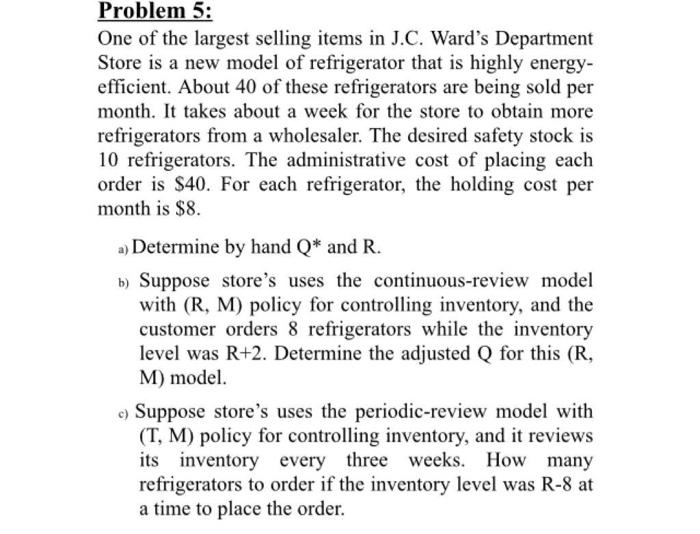

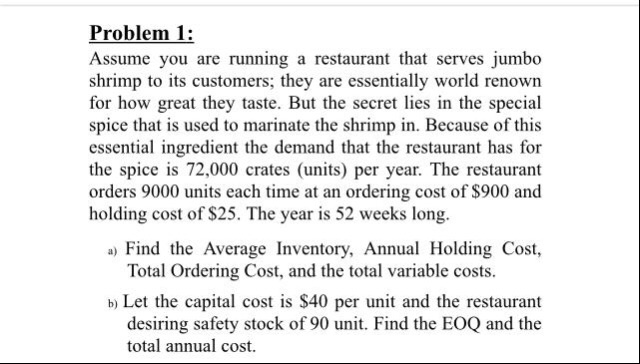

Problem 1: Assume you are running a restaurant that serves jumbo shrimp to its customers they are essentially world renown for how great they taste. But the secret lies in the special spice that is used to marinate the shrimp in. Because of this essential ingredient the demand that the restaurant has for the spice is 72,000 crates (units) per year. The restaurant orders 9000 units each time at an ordering cost of $900 and holding cost of $25. The year is 52 weeks long. a) Find the Average Inventory, Annual Holding Cost, Total Ordering Cost, and the total variable costs. b) Let the capital cost is $40 per unit and the restaurant desiring safety stock of 90 unit. Find the EOQ and the total annual cost. Problem 2: Food Town wishes to determine an optimal order policy for Marino brand pasta. The store sells an average of 320 one-pound packages per week. The cost of placing an order is S30, and the annual holding cost rate is estimated to be 14%. The pasta costs the store $.60 per package. Lead time is estimated to be one week, and the store desires a safety stock of 100 packages. a) How many packages of pasta should Food Town order? b) At what inventory level should the order be placed? Problem 3: Bee's Candy manufactures a variety of candy bars in a number of different sizes. One of its more popular products is the three-ounce Smirk bar. Bee's forecasts that demand for this product should be fairly constant over the next year, totaling 21 million bars. The candy production line, which operates 24 hours a day, 365 days a year, is capable of producing two candy bars per second. A production setup for the three-ounce Smirk bar takes 50 minutes and costs approximately S450. The annual holding cost of a three-ounce Smirk bar is estimated as $0.12 a) What is the optimal production batch size and the length of a production run in hours (including setup b) What is the total annual inventory holding and c What is the number of days between the start times of d) How would your answers to part (a) change if the time)? production setup cost for this policy? successive production runs? annual holding cost decreased to $0.10 per bar? Problem 4: Tim Madsen is the purchasing agent for Computer Center, a large discount computer store. He has recently added the hottest new computer, the Power model, to the store's stock of goods. Sales of this model now are running at about 13 per week. Tim purchases these customers directly from the manufacturer at a unit cost of $3,000, where each shipment takes half a week to arrive. Tim routinely uses the basic EOQ model to determine the store's inventory policy for each of its more important products. For this purpose, he estimates that the annual cost of holding items in inventory is 20 percent of their purchase cost. He also estimates that the administrative cost associated with placing each order is $75. a) Tim currently is using the policy of ordering 5 Power model computers at a time, where each order is timed to have the shipment arrive just about when the inventory of these computers is being depleted. Use the Solver version of the Excel template for the basic EoQ model to determine the various annual costs being incurred with this policy. b) Use this same spreadsheet to generate a table that shows how these costs would change if the order quantity were changed to the following values: 5,7,9, c Use the Solver to find the optimal order quantity Problem 5: One of the largest seling items in J.C. Ward's Department Store is a new model of refrigerator that is highly energy efficient. About 40 of these refrigerators are being sold per month. It takes about a week for the store to obtain more refrigerators from a wholesaler. The desired safety stock is 10 refrigerators. The administrative cost of placing each order is $40. For each refrigerator, the holding cost per month is $8 a) Determine by hand Q* and R. b) Suppose store's uses the continuous-review model with (R, M) policy for controlling inventory, and the customer orders 8 refrigerators while the inventory level was R+2. Determine the adjusted Q for this (R, M) model Suppose store's uses the periodic-review model with (T, M) policy for controlling inventory, and it reviews its inventory every three weeks. How many refrigerators to order if the inventory level was R-8 at a time to place the order