Question

Solve the following using LP. Golf-Sport is a small-sized company that produces high-quality components for people who build their own golf clubs and prebuilt sets

Solve the following using LP.

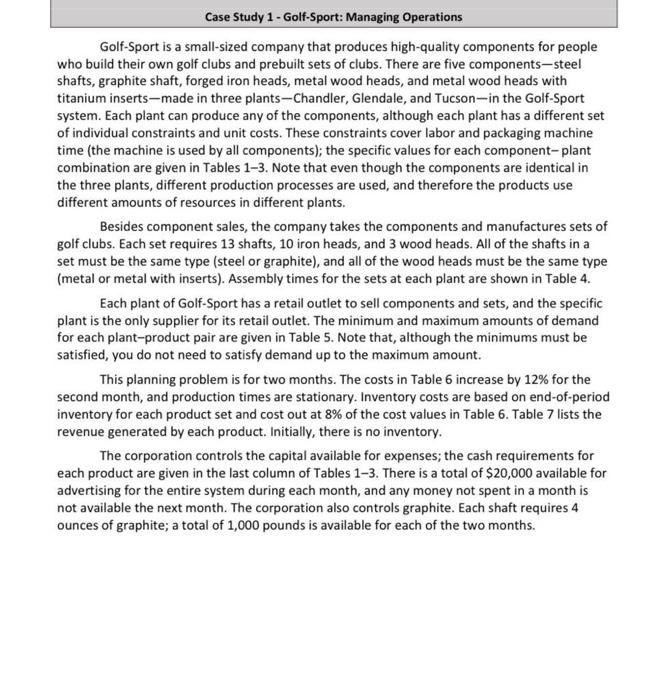

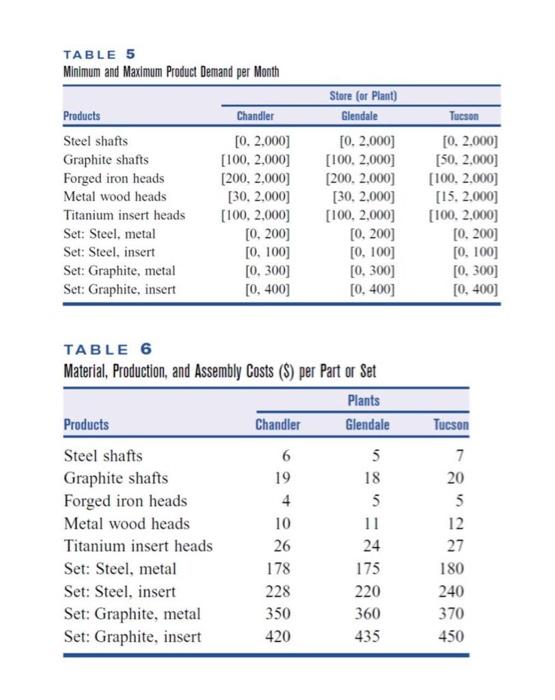

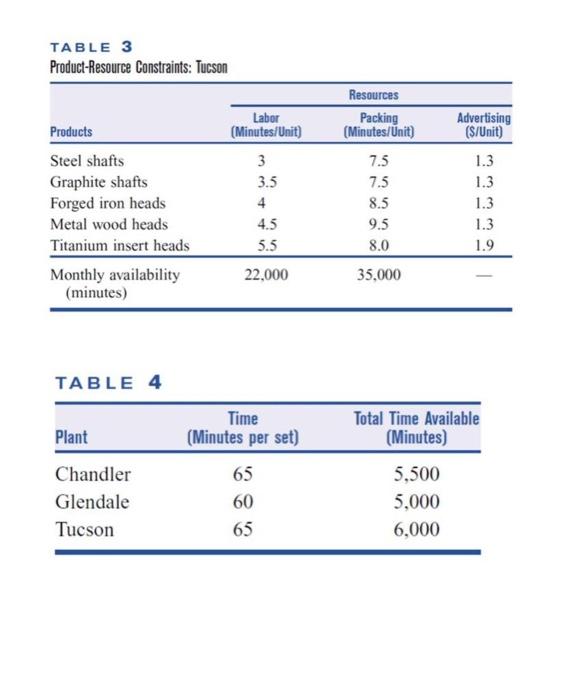

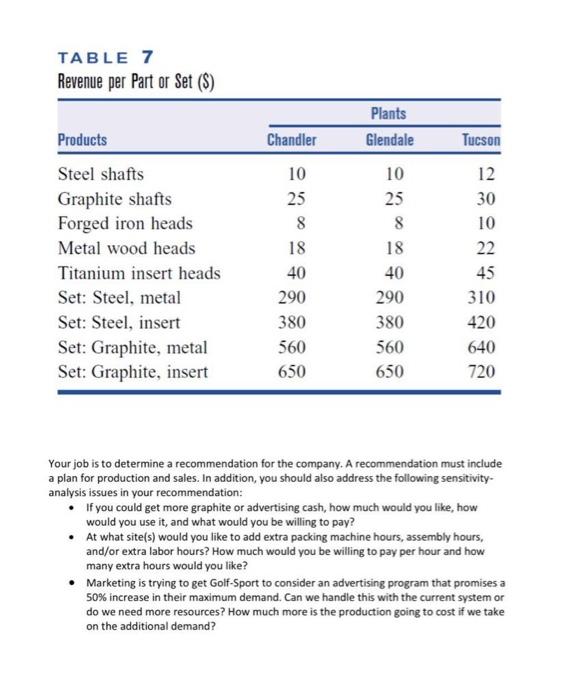

Golf-Sport is a small-sized company that produces high-quality components for people who build their own golf clubs and prebuilt sets of clubs. There are five components? steel shafts, graphite shaft, forged iron heads, metal wood heads, and metal wood heads with titanium inserts? made in three plants? Chandler, Glendale, and Tucson? in the Golf-Sport system. Each plant can produce any of the components, although each plant has a different set of individual constraints and unit costs. These constraints cover labor and packaging machine time (the machine is used by all components); the specific values for each component- plant combination are given in Tables 1-3. Note that even though the components identical in the three plants, different production processes are used, and therefore the products use different amounts of resources in different plants. Besides component sales, the company takes the components and manufactures sets of golf clubs. Each set requires 13 shafts, 10 iron heads, and 3 wood heads. All of the shafts in a set must be the same type (steel or graphite), and all of the wood heads must be the same type (metal or metal with inserts). Assembly times for the sets at each plant are shown in Table 4. Each plant of Golf-Sport has a retail outlet to sell components and sets, and the specific plant is the only supplier for its retail outlet. The minimum and maximum amounts of demand for each plant-product pair are given in Table 5. Note that, although the minimums must be satisfied, you do not need to satisfy demand up to the maximum amount. This planning problem is for two months. The costs in Table 6 increase by 12% for the second month, and production times are stationary. Inventory costs are based on end-of-period inventory for each product set and cost out at 8% of the cost values in Table 6. Table 7 lists the revenue generated by each product. Initially, there is no inventory. The corporation controls the capital available for expenses; the cash

Solve the following using LP ( only linear programming ) by lingo / kendo or excel (no written answers please) .

Case Study 1-Golf-Sport: Managing Operations Golf-Sport is a small-sized company that produces high-quality components for people who build their own golf clubs and prebuilt sets of clubs. There are five components-steel shafts, graphite shaft, forged iron heads, metal wood heads, and metal wood heads with titanium inserts-made in three plants-Chandler, Glendale, and Tucson-in the Golf-Sport system. Each plant can produce any of the components, although each plant has a different set of individual constraints and unit costs. These constraints cover labor and packaging machine time (the machine is used by all components); the specific values for each component-plant combination are given in Tables 1-3. Note that even though the components are identical in the three plants, different production processes are used, and therefore the products use different amounts of resources in different plants. Besides component sales, the company takes the components and manufactures sets of golf clubs. Each set requires 13 shafts, 10 iron heads, and 3 wood heads. All of the shafts in a set must be the same type (steel or graphite), and all of the wood heads must be the same type (metal or metal with inserts). Assembly times for the sets at each plant are shown in Table 4. Each plant of Golf-Sport has a retail outlet to sell components and sets, and the specific plant is the only supplier for its retail outlet. The minimum and maximum amounts of demand for each plant-product pair are given in Table 5. Note that, although the minimums must be satisfied, you do not need to satisfy demand up to the maximum amount. This planning problem is for two months. The costs in Table 6 increase by 12% for the second month, and production times are stationary. Inventory costs are based on end-of-period inventory for each product set and cost out at 8% of the cost values in Table 6. Table 7 lists the revenue generated by each product. Initially, there is no inventory. The corporation controls the capital available for expenses; the cash requirements for each product are given in the last column of Tables 1-3. There is a total of $20,000 available for advertising for the entire system during each month, and any money not spent in a month is not available the next month. The corporation also controls graphite. Each shaft requires 4 ounces of graphite; a total of 1,000 pounds is available for each of the two months.

Step by Step Solution

There are 3 Steps involved in it

Step: 1

Get Instant Access to Expert-Tailored Solutions

See step-by-step solutions with expert insights and AI powered tools for academic success

Step: 2

Step: 3

Ace Your Homework with AI

Get the answers you need in no time with our AI-driven, step-by-step assistance

Get Started