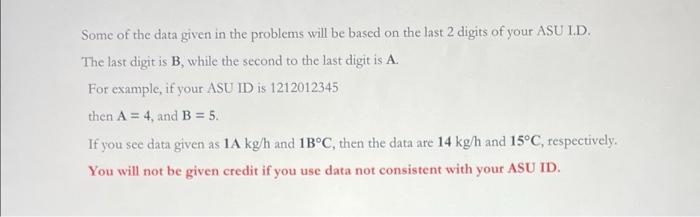

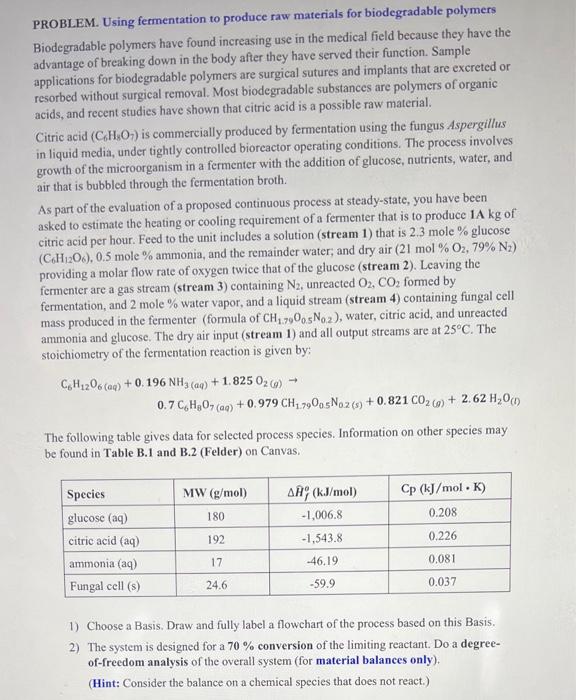

Some of the data given in the problems will be based on the last 2 digits of your ASU ID. The last digitis B, while the second to the last digit is A. For example, if your ASU ID is 1212012345 then A = 4, and B = 5. If you see data given as 1A kg/h and 13C, then the data are 14 kg/h and 15C, respectively. You will not be given credit if you use data not consistent with your ASU ID. PROBLEM. Using fermentation to produce raw materials for biodegradable polymers Biodegradable polymers have found increasing use in the medical field because they have the advantage of breaking down in the body after they have served their function Sample applications for biodegradable polymers are surgical sutures and implants that are excreted or resorbed without surgical removal. Most biodegradable substances are polymers of organic acids, and recent studies have shown that citric acid is a possible raw material. Citric acid (C.H.01) is commercially produced by fermentation using the fungus Aspergillus in liquid media, under tightly controlled bioreactor operating conditions. The process involves growth of the microorganism in a fermenter with the addition of glucose, nutrients, water, and air that is bubbled through the fermentation broth. As part of the evaluation of a proposed continuous process at steady-state, you have been asked to estimate the heating or cooling requirement of a fermenter that is to produce 1A kg of citric acid per hour. Feed to the unit includes a solution (stream 1) that is 2.3 mole % glucose (CH120), 0.5 mole % ammonia, and the remainder water, and dry air (21 mol % O2,79% N;) providing a molar flow rate of oxygen twice that of the glucose (stream 2). Leaving the fermenter are a gas stream (stream 3) containing N2, unreacted O2, CO2 formed by fermentation, and 2 mole % water vapor, and a liquid stream (stream 4) containing fungal cell mass produced in the fermenter (formula of CH 700sNoz), water, citric acid, and unreacted ammonia and glucose. The dry air input (stream 1) and all output streams are at 25C. The stoichiometry of the fermentation reaction is given by: CH1206(aq) +0.196 NH3(aq) +1.825 026) 0.7C.Hg07 (29) +0.979 CH1.79005No.2 (s) +0.821 CO2.() + 2.62 H3060) The following table gives data for selected process species. Information on other species may be found in Table B.1 and B.2 (Felder) on Canvas. MW (g/mol) 180 Cp (kJ/mol. K) 0.208 Species glucose (aq) citric acid (aq) ammonia (aq) Fungal cell (5) 192 ARY (kJ/mol) -1,006.8 -1,543.8 -46.19 -59.9 0.226 17 0.081 24.6 0.037 1) Choose a Basis. Draw and fully label a flowchart of the process based on this Basis, 2) The system is designed for a 70 % conversion of the limiting reactant. Do a degree- of-freedom analysis of the overall system (for material balances only) (Hint: Consider the balance on a chemical species that does not react.) 3) For a citric acid production rate of 1A kg/h, determine the total molar flow rates of the input and output streams (streams 1, 2, 3 and 4) and their compositions in mole %. Clearly show all equations and material balances used in your solution. 4) Find the Standard Heat of Reaction of the fermentation reaction, in kJ/mole glucose 5) If the feed solution (stream 1) enters the bioreactor at a temperature of 1B C, determine the rate at which heat must be added to or removed from (identify which) the fermenter, in kJ/h. Your solution must have an Enthalpy Table. Identify your reference states on top of the table. You may assume that aqueous reference states are also zero at 25C. Clearly show how you got the specific enthalpies of the input and output components. (Hint: Check how Problem 3 in Quiz 3 was solved in the Quiz 3 KEY) Some of the data given in the problems will be based on the last 2 digits of your ASU ID. The last digitis B, while the second to the last digit is A. For example, if your ASU ID is 1212012345 then A = 4, and B = 5. If you see data given as 1A kg/h and 13C, then the data are 14 kg/h and 15C, respectively. You will not be given credit if you use data not consistent with your ASU ID. PROBLEM. Using fermentation to produce raw materials for biodegradable polymers Biodegradable polymers have found increasing use in the medical field because they have the advantage of breaking down in the body after they have served their function Sample applications for biodegradable polymers are surgical sutures and implants that are excreted or resorbed without surgical removal. Most biodegradable substances are polymers of organic acids, and recent studies have shown that citric acid is a possible raw material. Citric acid (C.H.01) is commercially produced by fermentation using the fungus Aspergillus in liquid media, under tightly controlled bioreactor operating conditions. The process involves growth of the microorganism in a fermenter with the addition of glucose, nutrients, water, and air that is bubbled through the fermentation broth. As part of the evaluation of a proposed continuous process at steady-state, you have been asked to estimate the heating or cooling requirement of a fermenter that is to produce 1A kg of citric acid per hour. Feed to the unit includes a solution (stream 1) that is 2.3 mole % glucose (CH120), 0.5 mole % ammonia, and the remainder water, and dry air (21 mol % O2,79% N;) providing a molar flow rate of oxygen twice that of the glucose (stream 2). Leaving the fermenter are a gas stream (stream 3) containing N2, unreacted O2, CO2 formed by fermentation, and 2 mole % water vapor, and a liquid stream (stream 4) containing fungal cell mass produced in the fermenter (formula of CH 700sNoz), water, citric acid, and unreacted ammonia and glucose. The dry air input (stream 1) and all output streams are at 25C. The stoichiometry of the fermentation reaction is given by: CH1206(aq) +0.196 NH3(aq) +1.825 026) 0.7C.Hg07 (29) +0.979 CH1.79005No.2 (s) +0.821 CO2.() + 2.62 H3060) The following table gives data for selected process species. Information on other species may be found in Table B.1 and B.2 (Felder) on Canvas. MW (g/mol) 180 Cp (kJ/mol. K) 0.208 Species glucose (aq) citric acid (aq) ammonia (aq) Fungal cell (5) 192 ARY (kJ/mol) -1,006.8 -1,543.8 -46.19 -59.9 0.226 17 0.081 24.6 0.037 1) Choose a Basis. Draw and fully label a flowchart of the process based on this Basis, 2) The system is designed for a 70 % conversion of the limiting reactant. Do a degree- of-freedom analysis of the overall system (for material balances only) (Hint: Consider the balance on a chemical species that does not react.) 3) For a citric acid production rate of 1A kg/h, determine the total molar flow rates of the input and output streams (streams 1, 2, 3 and 4) and their compositions in mole %. Clearly show all equations and material balances used in your solution. 4) Find the Standard Heat of Reaction of the fermentation reaction, in kJ/mole glucose 5) If the feed solution (stream 1) enters the bioreactor at a temperature of 1B C, determine the rate at which heat must be added to or removed from (identify which) the fermenter, in kJ/h. Your solution must have an Enthalpy Table. Identify your reference states on top of the table. You may assume that aqueous reference states are also zero at 25C. Clearly show how you got the specific enthalpies of the input and output components. (Hint: Check how Problem 3 in Quiz 3 was solved in the Quiz 3 KEY)