Question

Some tasks and the order in which they must be performed according to their assembly requirements are shown in the following table. These are to

Some tasks and the order in which they must be performed according to their assembly requirements are shown in the following table. These are to be combined into workstations to create an assembly line. The assembly line operates 9 hours per day. The output requirement is 900 units per day.

| TASK | PRECEDING TASKS | TIME (SECONDS) |

|---|---|---|

| A | 29 | |

| B | A | 17 |

| C | A | 15 |

| D | B | 12 |

| E | B | 14 |

| F | C | 19 |

| G | C | 20 |

| H | D | 9 |

| I | E | 8 |

| J | F, G | 16 |

| K | H, I | 8 |

| L | J, K | 7 |

A. What is the required workstation cycle time to meet the desired output rate?

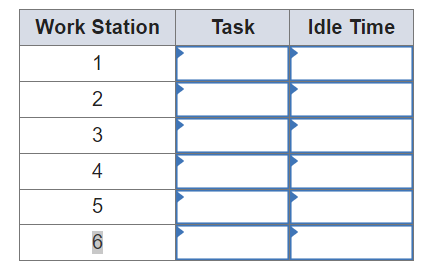

B. Balance the line using the longest task time based on the 900-unit forecast, stating which tasks would be done in each workstation.

Note: Leave no cells blank - be certain to enter "0" wherever required.

C. What is the efficiency of your line balance, assuming it is running at the cycle time determined in part a?

Note: Round your answer to 1 decimal place.

D. After production was started, Marketing realized that they had understated demand and must increase output to 1,000 units. What action would you take?

Note: Round your answer for cycle time down to the nearest whole number.

Round your answer for overtime up to the nearest whole number.

\begin{tabular}{|c|c|c|} \hline Work Station & Task & Idle Time \\ \hline 1 & & \\ \hline 2 & & \\ \hline 3 & & \\ \hline 4 & & \\ \hline 5 & & \\ \hline 6 & & \\ \hline \end{tabular}

Step by Step Solution

There are 3 Steps involved in it

Step: 1

Get Instant Access to Expert-Tailored Solutions

See step-by-step solutions with expert insights and AI powered tools for academic success

Step: 2

Step: 3

Ace Your Homework with AI

Get the answers you need in no time with our AI-driven, step-by-step assistance

Get Started