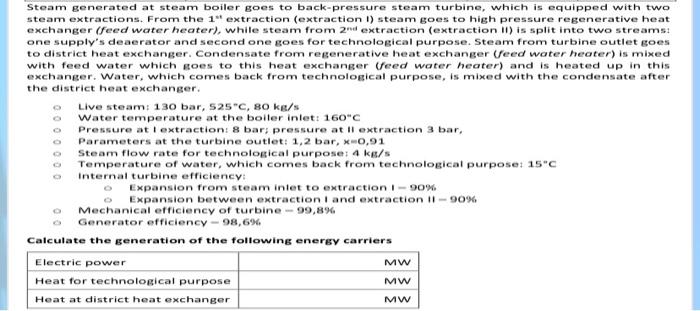

Steam generated at steam boiler goes to back-pressure steam turbine, which is equipped with two steam extractions. From the 1" extraction (extraction 1) steam goes to high pressure regenerative heat exchanger (feed water heater), while steam from 2nd extraction (extraction 11) is split into two streams: one supply's deaerator and second one goes for technological purpose. Steam from turbine outlet goes to district heat exchanger. Condensate from regenerative heat exchanger (eed water heater) is mixed with feed water which goes to this heat exchanger teed water heater) and is heated up in this exchanger. Water, which comes back from technological purpose, is mixed with the condensate after the district heat exchanger. Live steam: 130 bar, 525 "C, 80 kg/s Water temperature at the boiler inlet: 160"C Pressure at I extraction: 8 bar, pressure at Il extraction 3 bar, Parameters at the turbine outlet: 1,2 bar, x 0,91 Steam flow rate for technological purpose: 4 kg/s Temperature of water, which comes back from technological purpose: 15" Internal turbine efficiency: 0 Expansion from steam intet to extraction - 90% Expansion between extraction and extraction II - 90% Mechanical efficiency of turbine - 99,8% Generator efficiency-98,6% Calculate the generation of the following energy carriers Electric power MW Heat for technological purpose MW Heat at district heat exchanger MW 0000000 Steam generated at steam boiler goes to back-pressure steam turbine, which is equipped with two steam extractions. From the 1" extraction (extraction 1) steam goes to high pressure regenerative heat exchanger (feed water heater), while steam from 2nd extraction (extraction 11) is split into two streams: one supply's deaerator and second one goes for technological purpose. Steam from turbine outlet goes to district heat exchanger. Condensate from regenerative heat exchanger (eed water heater) is mixed with feed water which goes to this heat exchanger teed water heater) and is heated up in this exchanger. Water, which comes back from technological purpose, is mixed with the condensate after the district heat exchanger. Live steam: 130 bar, 525 "C, 80 kg/s Water temperature at the boiler inlet: 160"C Pressure at I extraction: 8 bar, pressure at Il extraction 3 bar, Parameters at the turbine outlet: 1,2 bar, x 0,91 Steam flow rate for technological purpose: 4 kg/s Temperature of water, which comes back from technological purpose: 15" Internal turbine efficiency: 0 Expansion from steam intet to extraction - 90% Expansion between extraction and extraction II - 90% Mechanical efficiency of turbine - 99,8% Generator efficiency-98,6% Calculate the generation of the following energy carriers Electric power MW Heat for technological purpose MW Heat at district heat exchanger MW 0000000